Electric main shaft of turning and milling composite machine tool

A compound machine tool and electric spindle technology, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of inflexible start and stop, reduced life, low power, etc., and achieve good cooling effect and efficiency High, fast start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

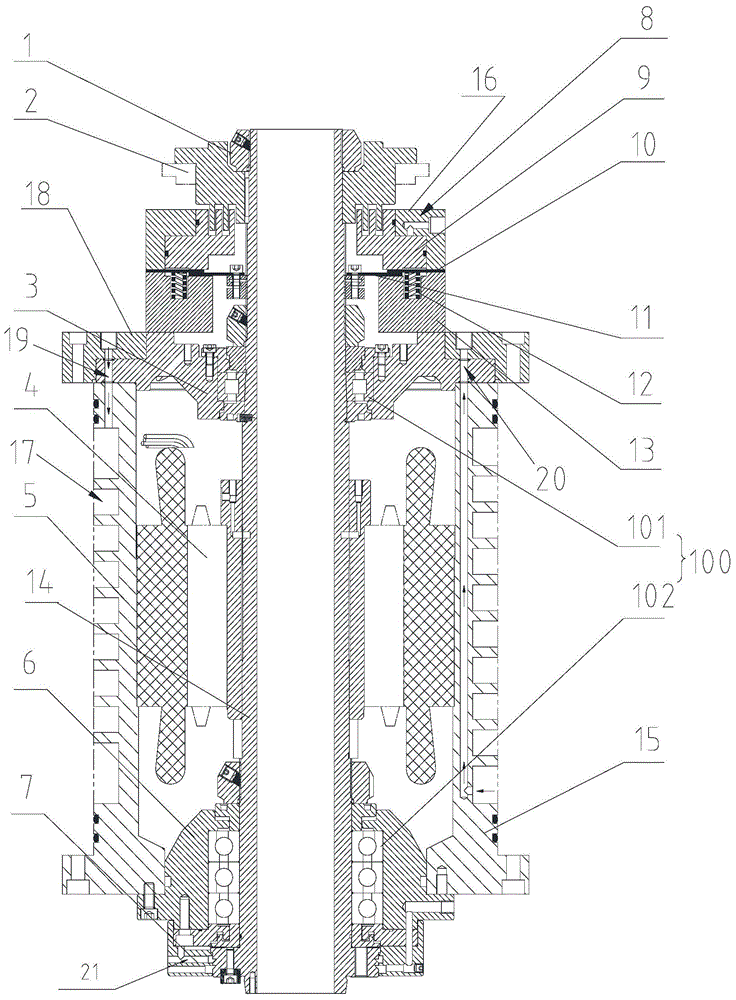

[0017] Such as figure 1 The electric spindle of a turning-milling compound machine tool shown includes a body 15, a shaft core 14, a rotor assembly 4, a stator assembly 5, a brake cylinder 8, a first stop ring 10, a second stop ring 11, a spring 12 and a fixed The seat 13, the shaft core 14 is pierced through the body 15 and pivotally connected with the body 15 through the bearing group 100, the stator assembly 5 is fixed on the inner wall of the body 15, the rotor assembly 4 is fixedly sleeved on the outer periphery of the shaft core 14 and is located in the stator assembly 5, The fixed seat 13 is fixed on the upper end of the body 15 and surrounds the outer side of the shaft core 14. The brake cylinder 8 includes a cylinder body 16 and a piston 9 installed in the cylinder body 16 to move telescopically along the axial direction of the shaft core 14. The cylinder body 16 and the fixed seat 13 is fixed, the first stop ring 10 is located between the bottom surface of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com