Quick changing device for partition board used for achieving dual stations of transverse cutting unit

A double-station and baffle technology is applied in the direction of shearing devices, shearing machine accessories, manufacturing tools, etc., to achieve the effects of improving work efficiency, reliable positioning, and simple and practical overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

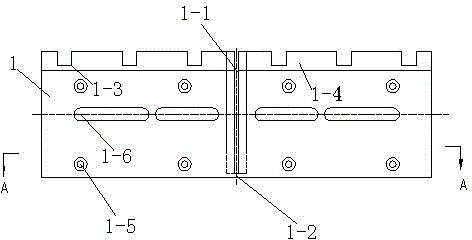

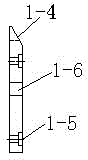

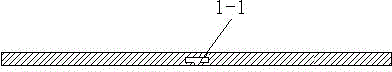

[0026] A reference to a cross-cut double-station quick-change partition device in this embodiment Figure 1-7 , it includes a partition base 1, the partition base 1 is processed by a steel plate with a thickness of 20mm, and the partition base 1 is provided with a T-shaped slot 1-1 with one end blocked, a roller hole 1-3, and an air hole 1-6 And bolt positioning holes 1-5, the upper side is provided with guide landslides 1-4 with large angle chamfers, which facilitates smooth guiding when the steel plate slides down. The bottom of the groove 1-1 is closed, and the T-type quick-change partition 2 cannot pass through, so that the T-type quick-change partition 2 is inserted into the T-type groove 1-1 and automatically positioned by gravity, and the positioning is reliable. The T-type quick-change separator 2 and the T-slot 1-1 are manufactured with tolerance requirements, and the gap is guaranteed to be between 0.05-0.2mm, which can not only be inserted and removed smoothly but a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com