Rubber-tube clamping linkage apparatus

A linkage device and clamping device technology, applied in the field of mechanical clamping, can solve the problems of slow speed and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

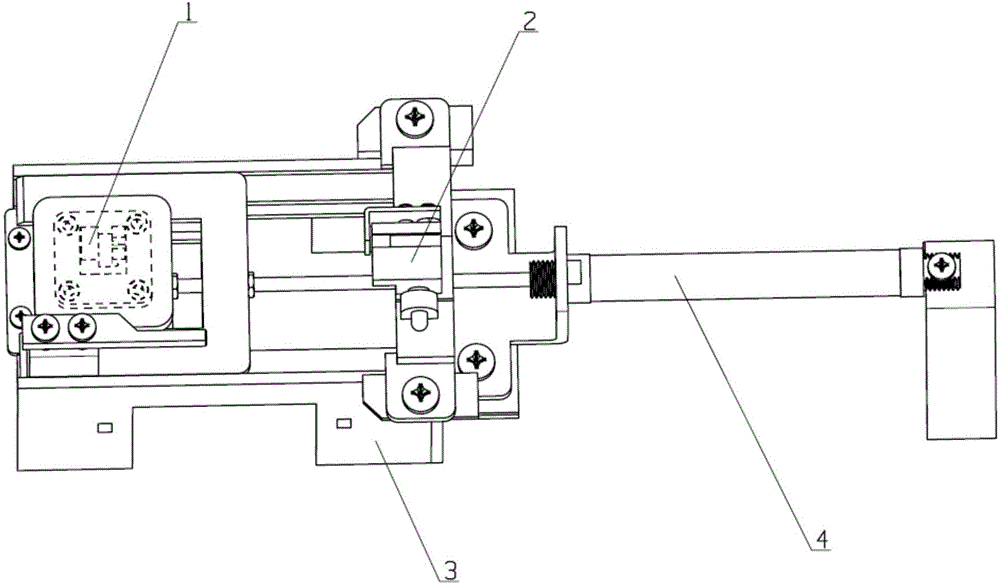

[0023] Such as figure 1 and Figure 7 As shown, a rubber hose clamping linkage device of the present invention includes a stamping mechanism 1, a clamping device 2, a fixed worktable 3 and a cylinder 4, and the stamping mechanism 1 is screwed to the piston rod end 41 of the cylinder 4 through a first nut 401 , the clamping device 2 is installed on the fixed workbench 3 through double screws, and the cylinder 4 is installed on the fixed workbench 3 horizontally.

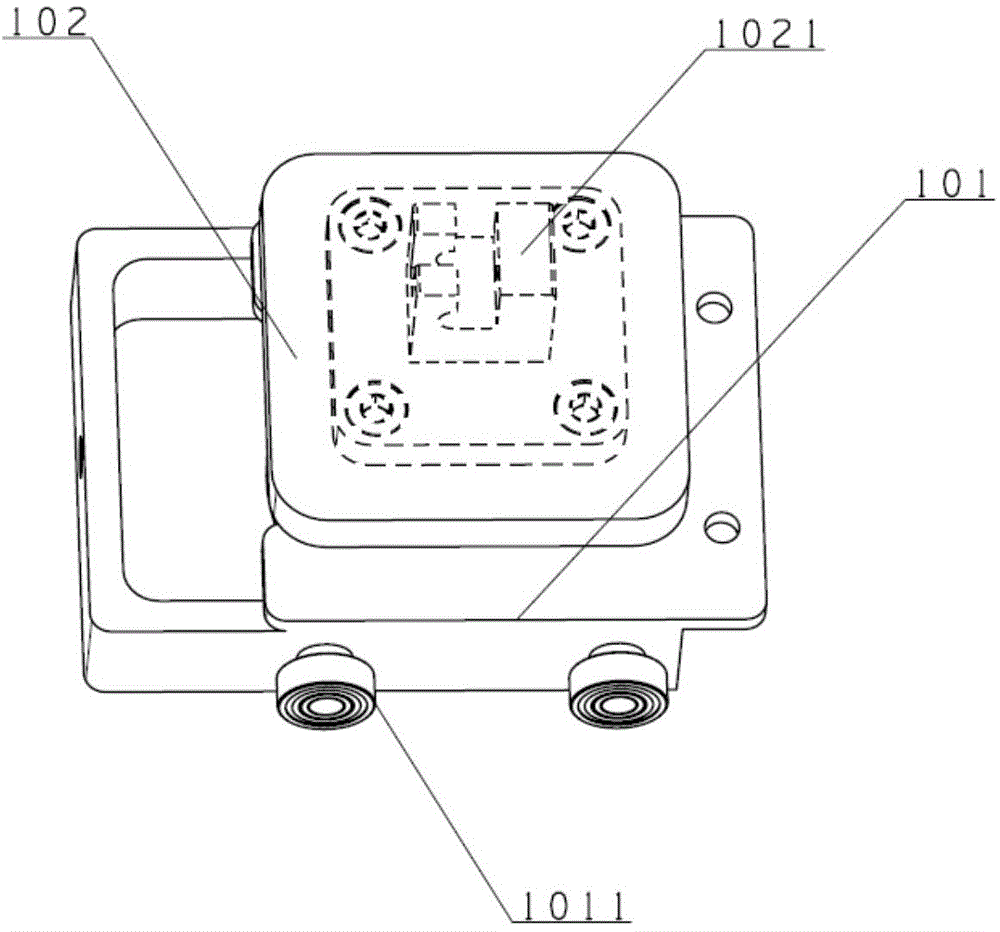

[0024] Such as figure 2 As shown, the stamping mechanism includes a feed trolley 101 and a joint installation platform 102. The feed trolley 101 is designed and installed on the second slide rail 304 of the fixed workbench 2 with bilateral symmetrical rollers 1011. The joint installation platform 102 is provided with a rubber hose joint clamp The holding structure 1021 is used for multi-station joint installation. The joint installation table 102 is installed on the feed trolley 101, and the feed trolley 101 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com