A guide mechanism for material boxing

A guiding mechanism and boxing technology, applied in the direction of packaging, etc., can solve the problems that materials cannot enter the packaging box smoothly, affect the packaging quality, and the sticking is not very good, etc., and achieve the effect of simple mechanism, reasonable design and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

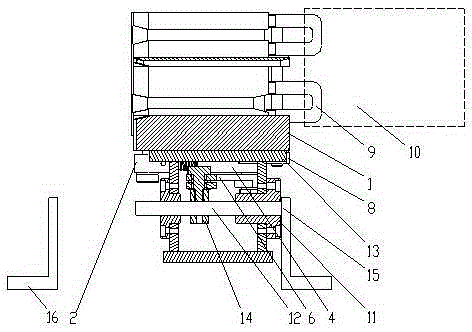

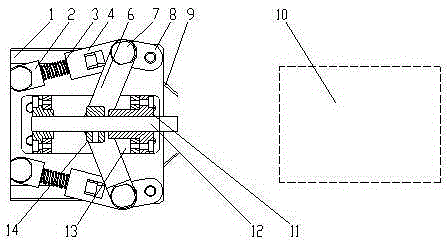

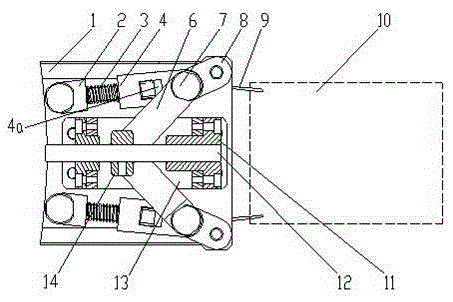

[0012] Such as figure 1 , figure 2 As shown, a material cartoning guide mechanism of the present invention consists of 1 feeding plate, 2 spring rods, 3 springs, 4 supporting rods, 6 connecting rods, 7 rotating pins, 8 short rods, 9 guide plates, 11 supporting sleeves, 12 telescopic shaft, 13 connecting seat, 14 connecting block, 15 front impact plate and 16 rear impact plate. The connecting seat 13 is fixed on the feeding plate 1, and the supporting shaft sleeve 11 is installed on the connecting seat 13. 12 is installed in the supporting shaft sleeve 11, the connecting block 14 is fixed on the telescopic shaft 12 by top screws, a pair of connecting rods 6 are symmetrically installed on the connecting block 14, the connecting rod 6 short rod 8 and the supporting rod 4 are passed through the rotating pin 7 are connected together in a symmetrical distribution, the support rod 4 and the spring 3 are mounted on the spring rod 2, the spring rod 2 is mounted on the feeding plate 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com