A multifunctional creel system

A creel and multi-functional technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of inaccurate control, inability to adjust the position, and non-adjustable position, so as to avoid yarn wear, Ease of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

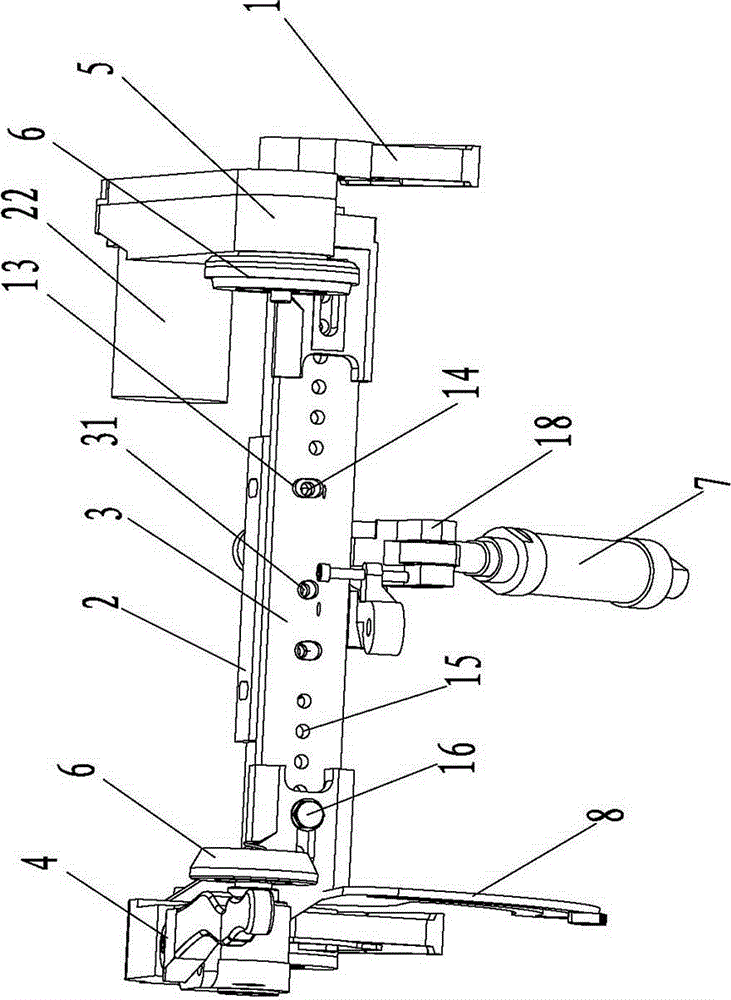

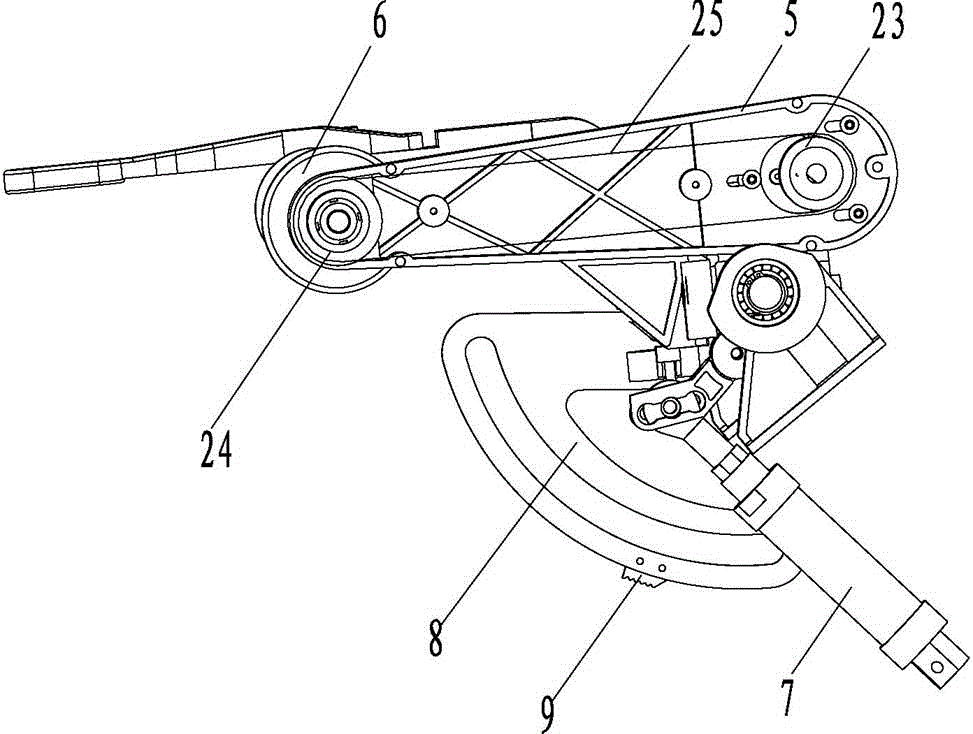

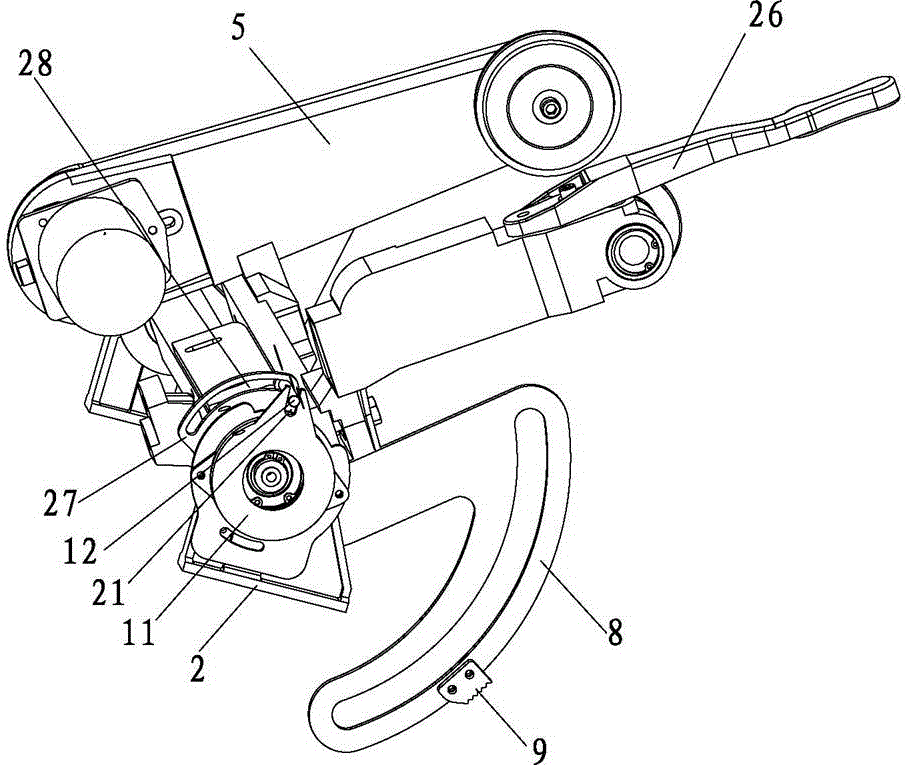

[0030] Please refer to the attached figure 1 to attach Figure 7 As shown, the present invention is a multifunctional creel system, which consists of a frame 1, a base plate 2, a mounting plate 3, a left arm 4, a right arm 5, a top plate 6, a cylinder 7, a rotating arm 8, a clamping plate 9, Movable support plate 10, potentiometer 11 and driving lever 12 etc. are made up of several parts.

[0031] Wherein, the base plate 2 is pivotally connected to the frame 1 so that it can be turned upside down.

[0032] The mounting plate 3 is pivotally connected to the base plate 2 through a pin shaft 31 , so that the mounting plate 3 can rotate relative to the base plate 2 . The mounting plate 3 is provided with an elliptical hole 13 on both sides of the pin shaft 12; a pair of screws 14 pass through the elliptical hole 13 and are screwed to the base plate 2, so as to realize the fixing of the base plate 2 and the mounting plate 2.

[0033] The mounting plate 3 is provided with several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com