A kind of preparation method of separator for high-strength lithium-ion battery

A lithium-ion battery, high-strength technology, applied to battery components, circuits, electrical components, etc., can solve the problems of low physical properties and high conductivity of polymer separators, and achieve the effect of decreased conductivity and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

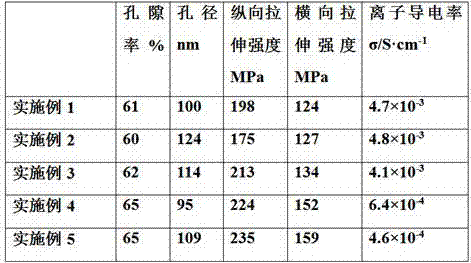

Examples

Embodiment 1

[0023] The preparation method of high-strength lithium-ion battery diaphragm, the steps are:

[0024] Step 1: Take 60Kg of polypropylene, 4Kg of silicon carbide powder, 3Kg of titanium oxide powder, 8Kg of chlorinated polyethylene, 4Kg of stearic acid, 5Kg of polysulfide rubber, 1Kg of tolyldiureidosilane, and plasticizer phthalic acid Dioctyl 4Kg, mixed evenly, put into the side feed hopper of the twin-screw extruder, melted, kneaded, extruded, cooled, dried, pelletized, and film-made to obtain the base material, the screw of the twin-screw extruder The temperature is controlled between 180°C and the screw speed is controlled at 170 rpm;

[0025] Step 2, zirconia powder 5Kg, pentaerythritol stearate 2Kg, surfactant lecithin 4Kg, antioxidant (antioxidant 1010) 0.5Kg, stabilizer dibutyltin dilaurate 0.5Kg, organic solvent, stir Uniformly, a mixed solution is obtained;

[0026] Step 3: Heat the substrate to 90°C and keep it for 60 minutes, then at this temperature, apply the m...

Embodiment 2

[0028] The preparation method of high-strength lithium-ion battery diaphragm, the steps are:

[0029] Step 1: Take 100Kg of polypropylene, 10Kg of silicon carbide powder, 6Kg of titanium oxide powder, 16Kg of chlorinated polyethylene, 10Kg of stearic acid, 10Kg of polysulfide rubber, 3Kg of tolyldiureidosilane, and plasticizer phthalic acid Dioctyl ester 8Kg, mix evenly, put into the side feeding hopper of twin-screw extruder, melt, knead, extrude, cool, dry, cut into pellets, film-making, obtain base material, the screw of twin-screw extruder The temperature is controlled between 200°C and the screw speed is controlled at 190 rpm;

[0030] Step 2, mix 12Kg of zirconia powder, 5Kg of pentaerythritol stearate, 7Kg of surfactant lecithin, 0.8Kg of antioxidant (antioxidant 1010), 0.8Kg of stabilizer dibutyltin dilaurate, organic solvent, and stir Uniformly, a mixed solution is obtained;

[0031] Step 3. Heat the base material to 110°C and keep it for 90 minutes. Then, at this t...

Embodiment 3

[0033] The preparation method of high-strength lithium-ion battery diaphragm, the steps are:

[0034] Step 1: Take 80Kg of polypropylene, 8Kg of silicon carbide powder, 5Kg of titanium oxide powder, 12Kg of chlorinated polyethylene, 6Kg of stearic acid, 8Kg of polysulfide rubber, 2Kg of tolyldiureidosilane, and plasticizer phthalic acid Dioctyl ester 6Kg, mix uniformly, put into the side feeding hopper of twin-screw extruder, melt, knead, extrude, cool, dry, cut into pellets, film-making, obtain base material, the screw of twin-screw extruder The temperature is controlled between 190°C and the screw speed is controlled at 180 rpm;

[0035] Step 2, zirconia powder 8Kg, pentaerythritol stearate 4Kg, surfactant lecithin 5Kg, antioxidant (antioxidant 1010) 0.7Kg, stabilizer dibutyltin dilaurate 0.7Kg, organic solvent, stir Uniformly, a mixed solution is obtained;

[0036] Step 3: Heat the base material to 100°C and keep it for 80 minutes. Then, at this temperature, apply the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com