Vacuum magnetron sputtering coating magnetic suspension transmission device and application method

A technology of vacuum magnetron sputtering and transmission device, which is applied in the field of magnetic transmission, and can solve the difficulty of adjusting the transmission accuracy of guide rail distance, verticality and parallelism, the easy wear and tear of rack and pinion, guide rail and trolley sliding wheel, and the qualified rate of production products Low and other problems, to achieve the effect of significant operation, improve product quality, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

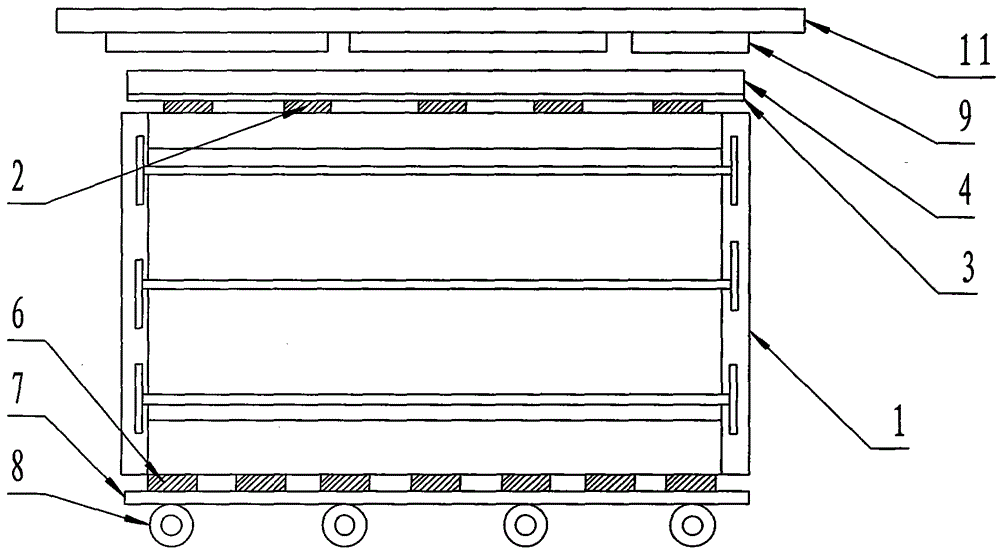

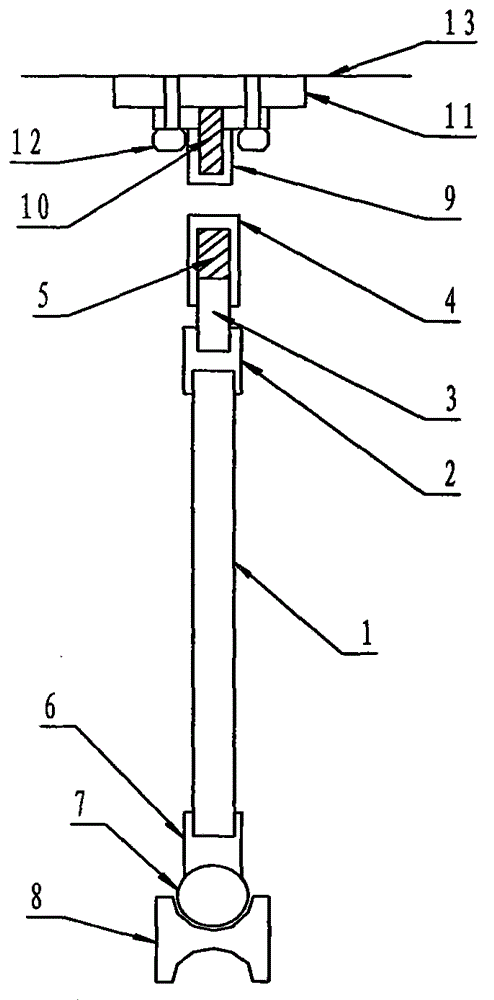

[0024] At least five upper insulating blocks 2 are arranged above the vehicle body 1, at least five lower insulating seats 6 are arranged below, and No. 1 magnetic shoe 3 is arranged between the top of the upper insulating block 2 and the inverted U-shaped magnet sheath 4, and the inverted U-shaped magnet A strong magnetic N pole 5 is set inside the sheath 4, a transmission guide rod 7 is set under the lower insulating seat 6, and the lower part of the drive guide rod 7 is set correspondingly to the transmission wheel 8 of the transmission system; a T-shaped magnet sheath is set above the inverted U-shaped magnet sheath 4 9. A magnetic field action space is reserved between the T-shaped magnet sheath 9 and the inverted U-shaped magnet sheath 4. The T-shaped magnet sheath 9 is provided with a strong magnetic S pole 10, and the T-shaped magnet sheath 9 is provided with a No. 2 magnetic shoe. 11. The T-shaped magnet sheath 9 is fixed on the No. 2 magnetic shoe 11 by screws 12, and...

Embodiment 2

[0026] The section of the upper insulating block 2 is H-shaped, and the upper and lower parts of the upper insulating block 2 form an upper and a lower card slot respectively, the lower card slot is set correspondingly to the top of the car body 1, and the upper card slot is connected to the No. 1 magnetic shoe 3 Corresponding settings below.

Embodiment 3

[0028] A magnet cavity is set in the T-shaped magnet sheath 9, and a strong magnetic S pole 10 is set in the magnet cavity; a magnet cavity is set in the inverted U-shaped magnet sheath 4, and a strong magnetic N pole 5 is set in the magnet cavity. The strong magnetic N pole 5 in the inverted U-shaped magnet sheath 4 corresponds to the top of the No. 1 magnetic shoe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com