Combined in-situ shallow layer geotherm measurement drill

A combined and in-situ technology, which is applied to drill bits, drilling equipment, and earthwork drilling and production, can solve problems such as measurement error, in-situ measurement, soil disturbance, etc., and achieve the effect of convenient installation, disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

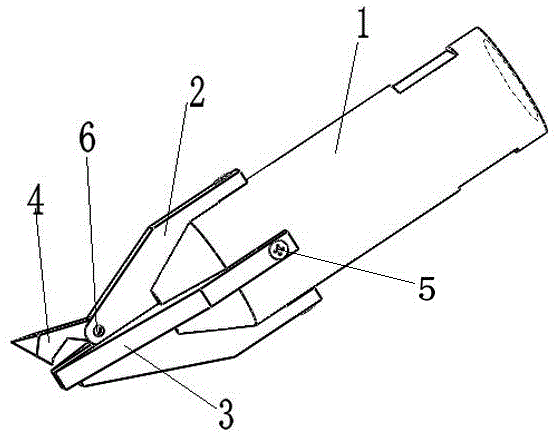

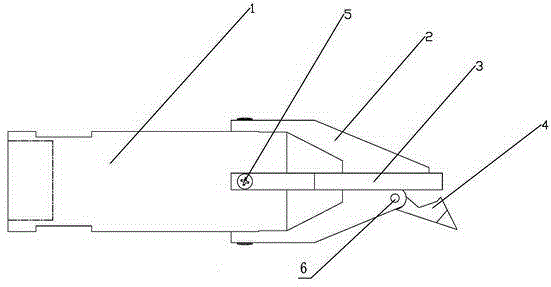

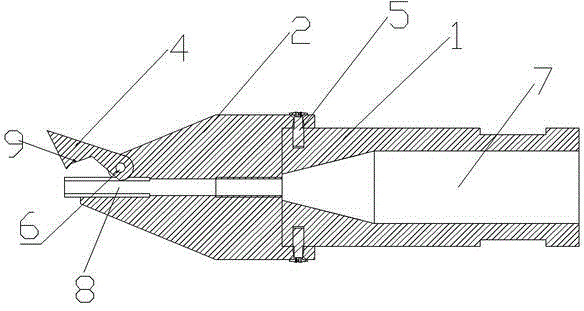

[0012] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment is composed of a drill body 1, a first cutting edge 2, a second cutting edge 3, a movable cone tip 4, a screw 5 and a pin 6. The front end of the drill body 1 is a conical structure and has a cross-shaped groove. The cone angle of the conical structure is 40°~60°. The first cutting edge 2 and the second cutting edge 3 are inserted into the cross-shaped groove and connected to the drill bit body 1 through the screw 5. The first cutting edge 2 and the second cutting edge 3 It is in the shape of a cross, and the maximum width of the first cutting edge 2 and the second cutting edge 3 is 3-5 mm larger than the outer diameter of the drill body 1 . The lower part of the movable cone point 4 is designed to be arc-shaped, and the movable cone point 4 is installed in the arc-shaped hole groove of the first cutting edge 2 through the pin 6. The movable cone point 4 is closely matched with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com