Mining method for transitioning underground ore bodies from open stope mining method to caving mining method

A caving mining and mining method technology, which is applied in the field of transition of underground mines from open-field mining to caving mining, can solve the problems of complex construction organization, high loss rate of ore recovery and poor operation safety, etc. The overall economic benefit of the deposit and the effect of extending the service life of the mine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

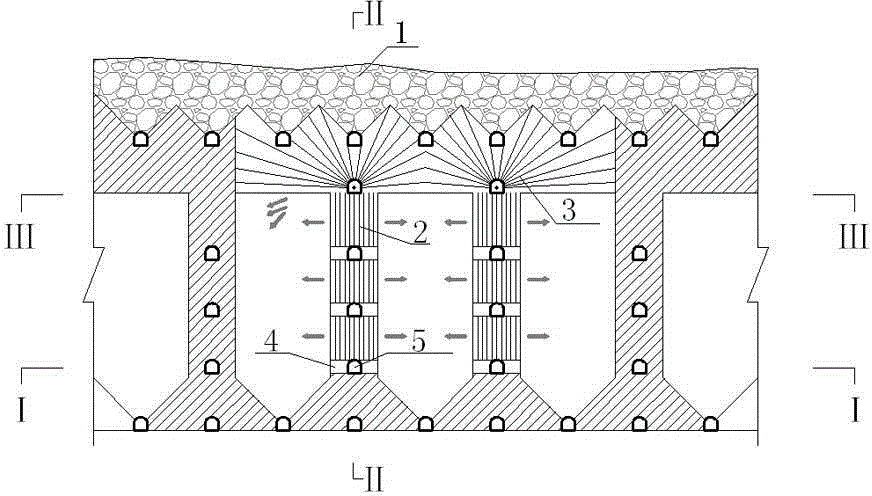

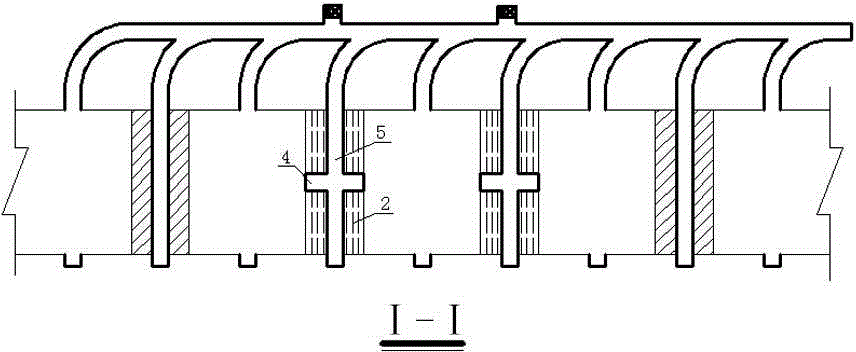

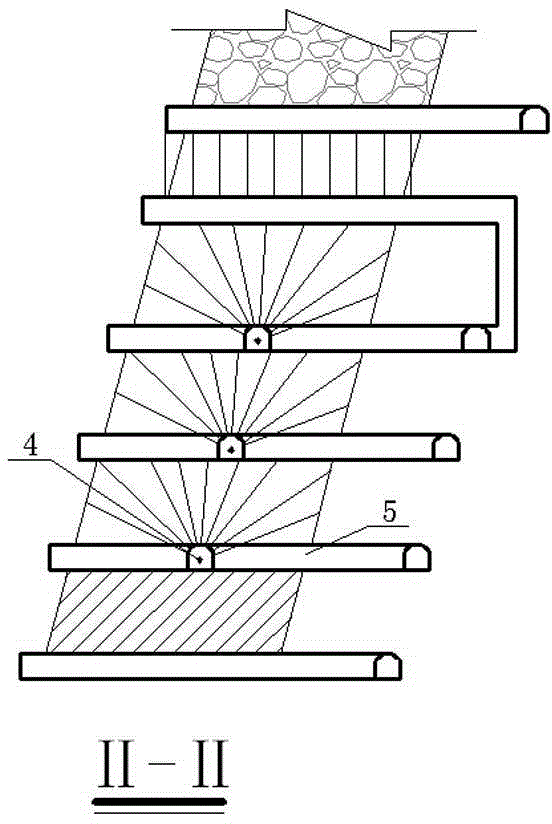

[0029] Taking an underground mine as an example, the mine was mined by the open-field method of segmental rock drilling in the early stage, and later changed to the segmental caving method without pillars due to changes in ore body conditions.

[0030] Specific steps are as follows:

[0031] Step 1: Division of Regions

[0032] 1) Determination of critical exposure area

[0033] The open field method in the segmented rock drilling stage is suitable for ore and surrounding rocks without large fault fracture zones, inclined and steeply inclined medium-thick ore bodies with firmness factor f≥6, tensile strength > 10MPa, and compressive strength > 50MPa. Pillarless segmented caving method is suitable for inclined and steeply inclined thick ore bodies with ore and surrounding rock firmness coefficient 6>f≥2, tensile strength>3MPa, compressive strength>15MPa. Therefore, it is necessary to change the open-field mining method to the caving mining method when encountering an ore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com