Separating flotation method of low-grade complex lead-antimony-zinc

A low-grade, lead-antimony-zinc technology, applied in flotation, solid separation, wet separation, etc., can solve problems that do not involve separation technology solutions, and achieve the goal of expanding resource utilization, improving economic benefits, and improving operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

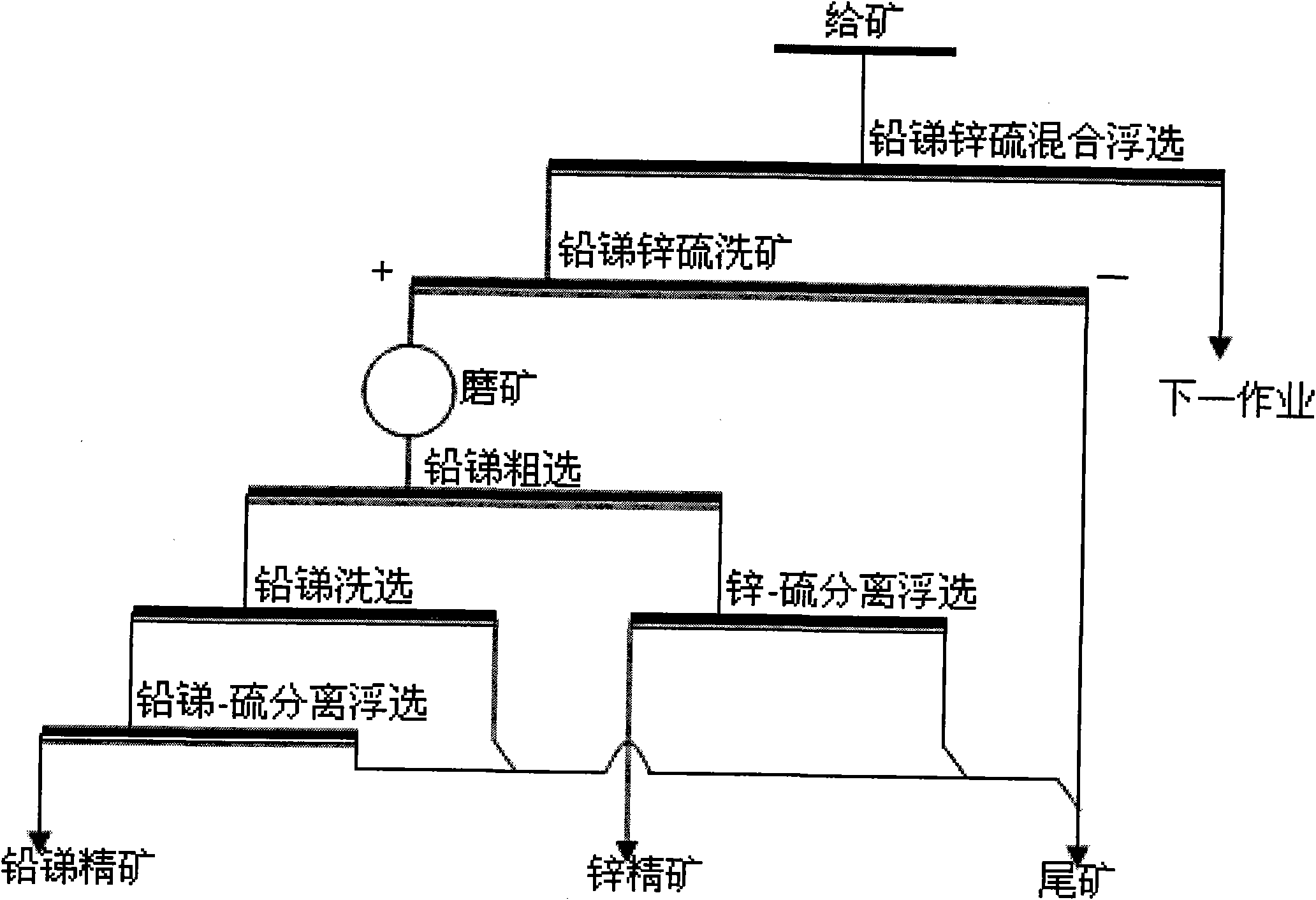

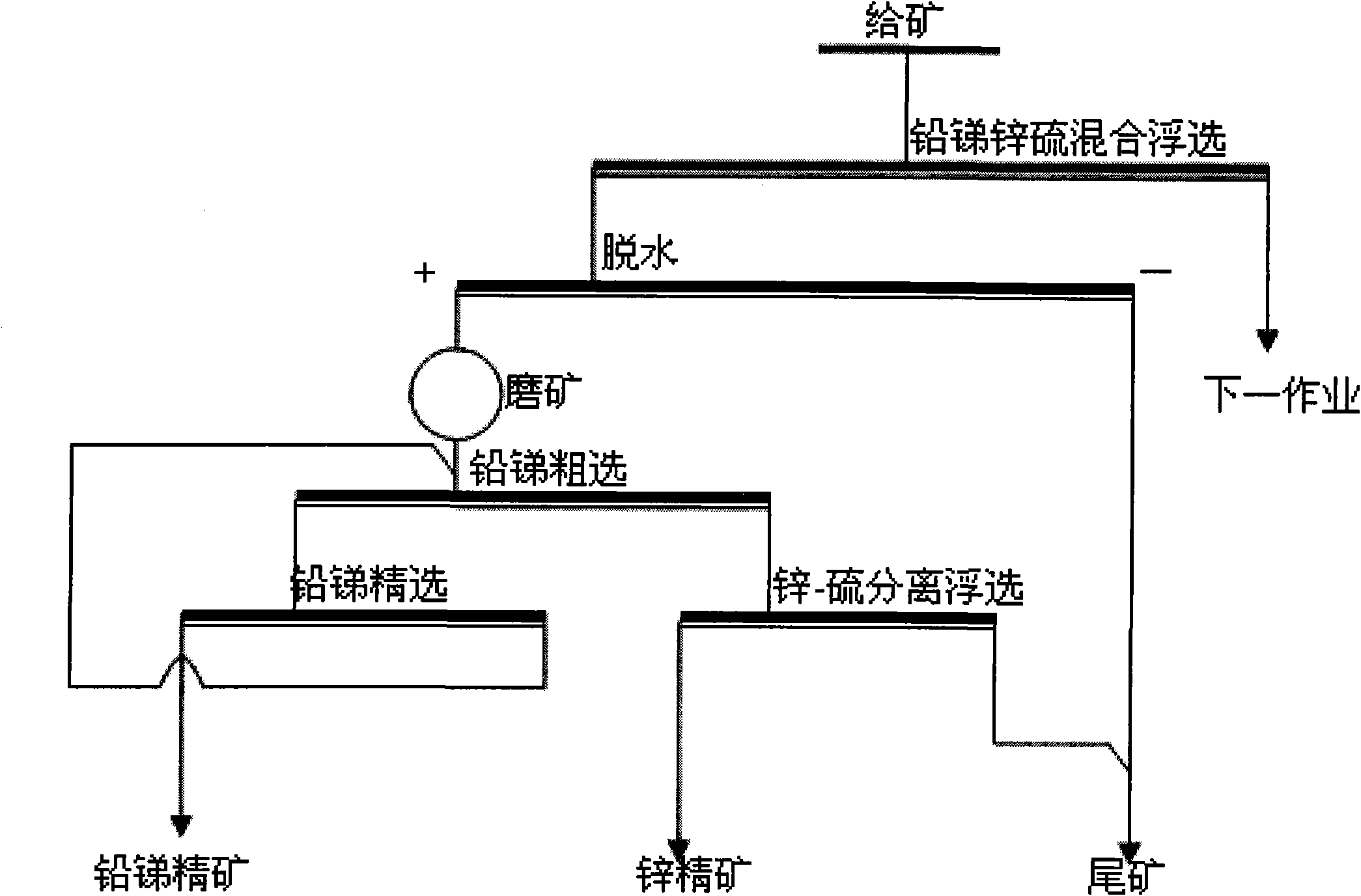

Method used

Image

Examples

Embodiment

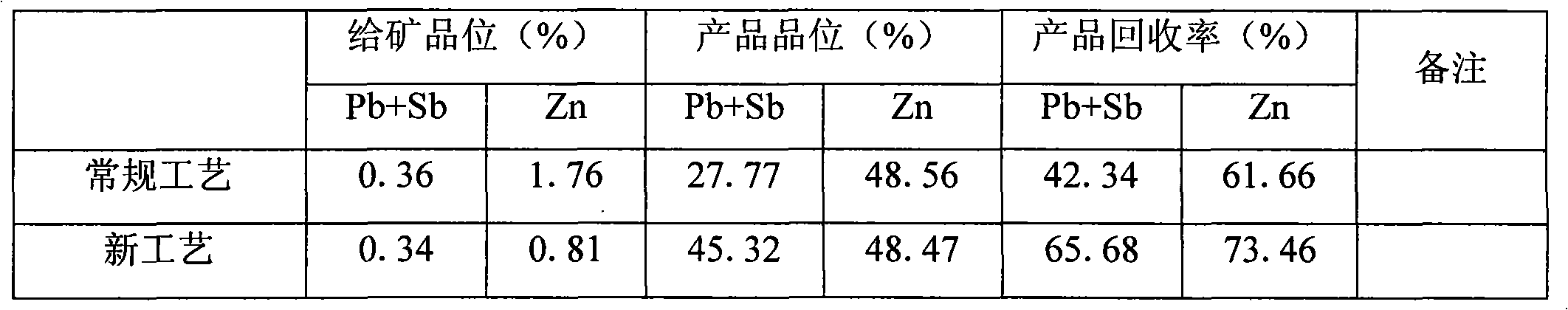

[0075] The present invention first performs mixed flotation on sulfide minerals containing lead + antimony 0.35% and zinc 1.8%, and then washes the produced foamed lead-antimony-zinc-sulfur mixed concentrate without adding any chemicals and only adding 4t / t The clear water is used in the thickener and classifier to remove the influence of excess chemicals, slime, and some impurities on the flotation, and the impurities and overflow are discarded as tailings; the surface pollution of the ore particles is cleaned again by the sand settling machine, Create fresh surface and create conditions for the action of chemicals; the ore pulp after grinding enters the roughing of lead and antimony with a concentration of 35%, adding 0.2Kg / t ethyl disulfide nitrogen, 0.15Kg / t zinc sulfate, and 0.1Kg / t sodium cyanide , 2.5Kg / t lime and other beneficiation agents, the output contains 2-6% lead and antimony, and the recovery rate of the operation is greater than 90%. The lead-antimony foam conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com