Piston ring structure

A piston ring and annular technology, which is applied in the field of internal combustion engines, can solve the problems of overcoming thermal deformation and achieve good self-adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

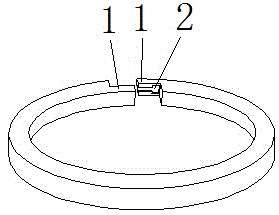

[0020] see figure 1 , figure 2 and image 3 , as can be seen from the figure, the telescopic piston ring of the engine of the present invention, the piston ring is disconnected to form two ports, and the two ports are connected to form a closed ring shape, and the two ports respectively have protrusions protruding forward for overlapping each other One of the protruding parts 1 protrudes smoothly from the inner wall of the end where it is located, and the other protruding part 1 protrudes smoothly along the outer wall of the end where it is located. The sum of the thicknesses of the two protruding parts is the wall thickness of the piston ring. A T-shaped rib is formed on the surface of one of the protrusions facing the other protrusion, and a T-shaped groove 2 for accommodating the T-shaped rib is formed on the opposite surface of the other protrusion. The height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com