Storage failure rate detecting method and storage reliability detecting method of infrared focal plane array chip

An infrared focal plane and array chip technology, applied in the field of infrared focal plane array detectors, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

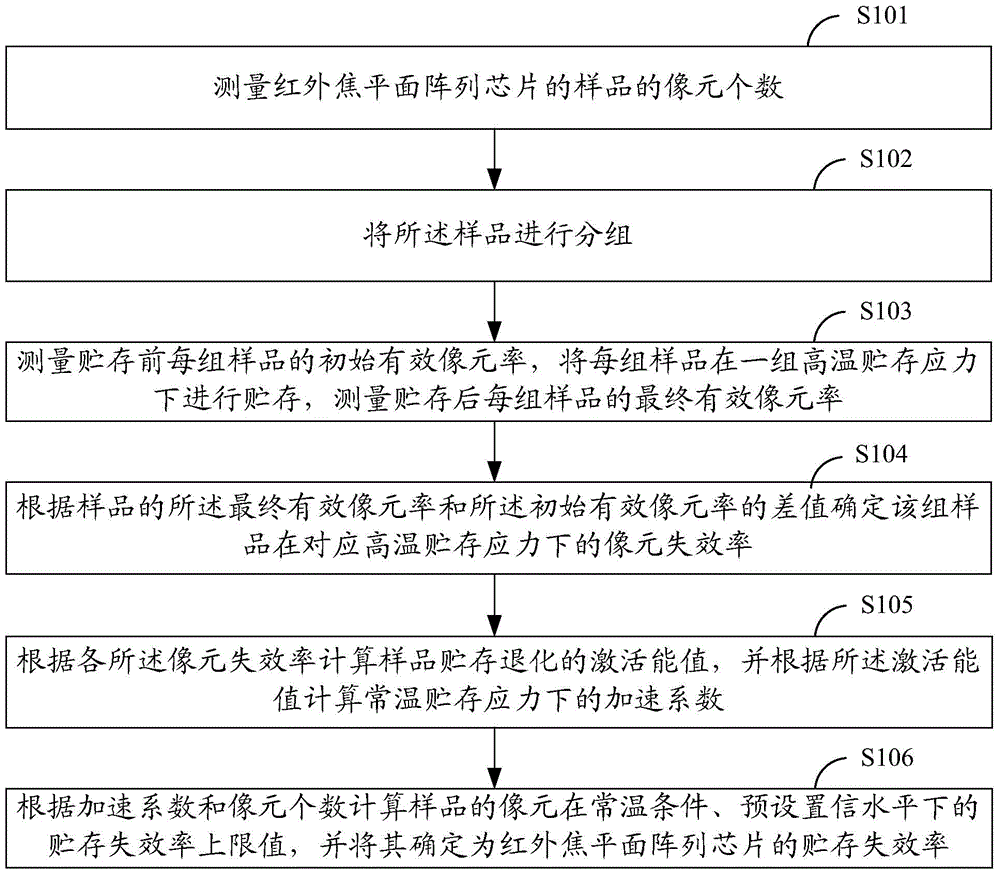

[0024] Such as figure 1 As shown, it is a schematic flow chart of an embodiment of a detection method for the storage failure rate of an infrared focal plane array chip of the present invention, including:

[0025] Step S101: measure the number of pixels of the sample of the infrared focal plane array chip;

[0026] The samples here are samples of the same infrared focal plane array chip. The IRFPA chip is composed of many pixels. For a M×N area array chip, the chip can be regarded as a sample matrix containing M×N units. Based on the degradation characteristics of IRFPA detector materials, high temperature is a sensitive stress that causes the degradation of its detector pixels. Therefore, grouped high-temperature storage tests were carried out to evaluate its storage fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com