Equipment for online detection of vacuum degree of cans and its inspection head

A technology of vacuum degree and canning, which is applied in the direction of vacuum gauge, measuring device, measuring fluid pressure, etc. It can solve the problems of high work intensity, large test error, high false detection and missed detection rate, and improve the inspection efficiency and speed up the printing process. The effect of checking speed and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

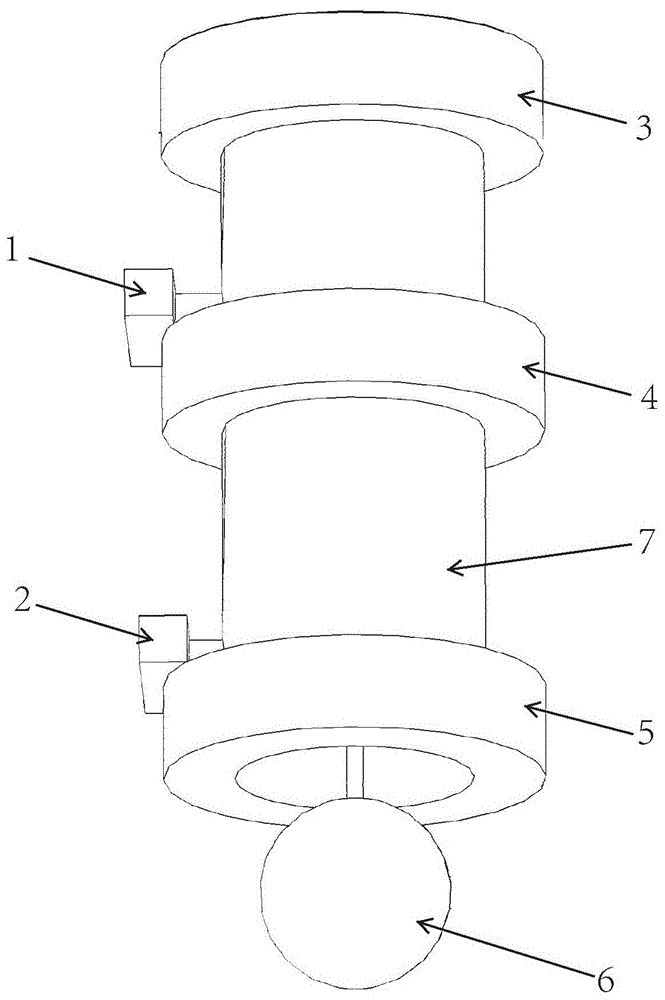

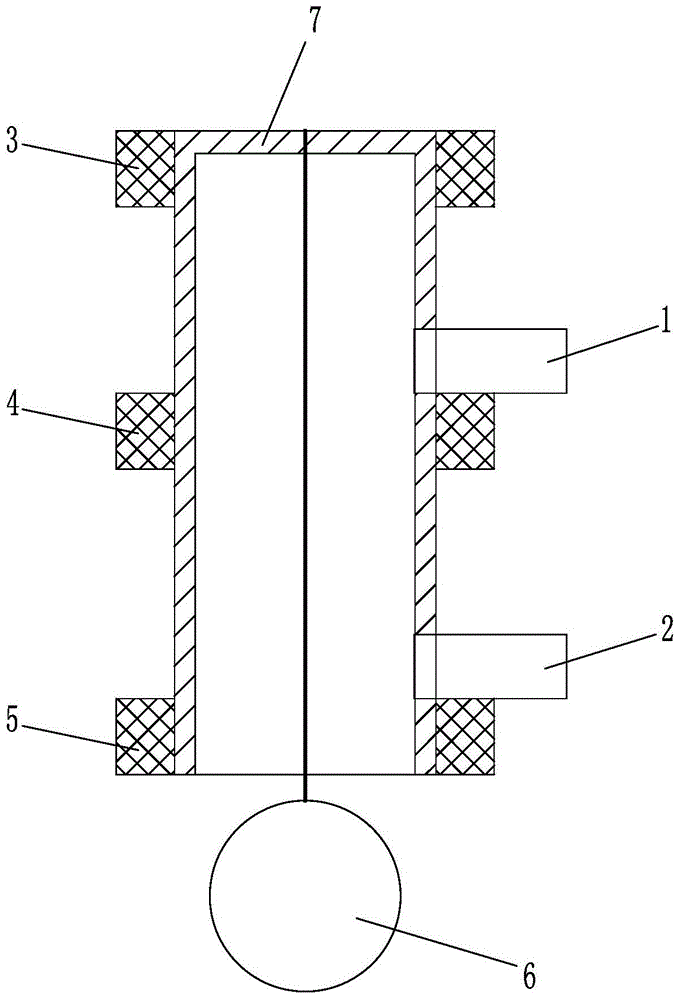

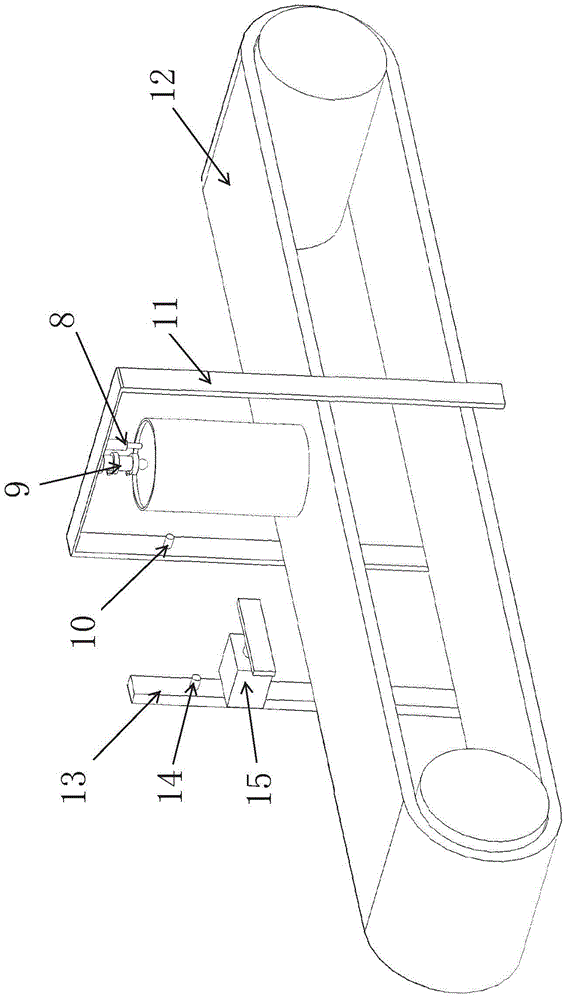

[0029] Such as figure 1 , figure 2 The shown inspection head includes a cylindrical inspection head housing 7, on which a coil A3, a coil B4 and a coil C5 are sequentially installed from top to bottom, and the inside of the inspection head housing 7 is suspended by a rope There is a metal percussion ball 6, which is located outside the inspection head shell 7 and below the coil C5 when the metal percussion ball 6 is naturally drooping. A metal percussion ball that can detect metal percussion balls is installed on the inspection head shell 7 between the coil A3 and the coil B4. 6, the photoelectric switch A1 of the inspection head, the inspection head housing 7 between the coil B4 and the coil C5 is equipped with the photoelectric switch B2 of the inspection head that can detect the metal knocking ball 6; when the inspection head is working, it includes the following steps:

[0030] 1) The coil A3 is energized, the coil B4 is energized for 5-50 milliseconds, and the metal per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com