A display with integrated touch function and its manufacturing method

A technology of touch function and display screen, which is applied in optics, instrumentation, electrical digital data processing, etc., can solve problems such as complex manufacturing process and waste of raw materials, achieve the effect of saving raw materials and manufacturing costs, and increasing the display aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

[0055] The present invention will be further described in detail through specific examples below.

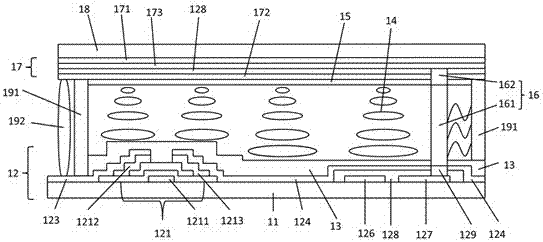

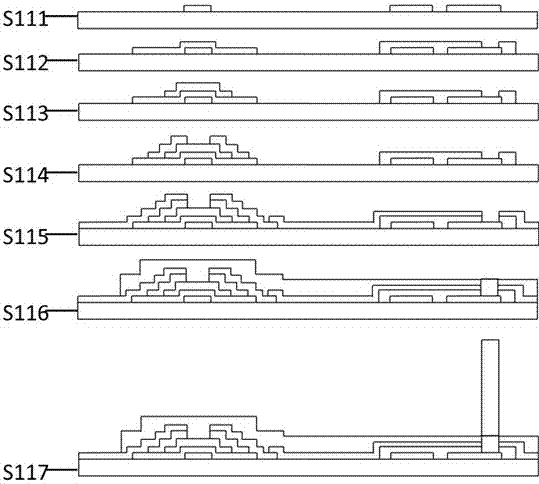

[0056] Such as Figure 1~2 , an integrated touch display screen and a manufacturing method thereof provided in this embodiment, the integrated touch screen includes:

[0057] a first substrate (11);

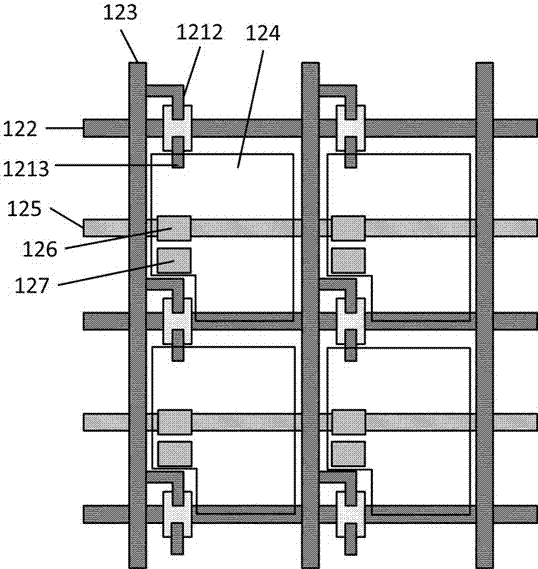

[0058]A thin film transistor layer; including TFT elements (121), first pixel scan lines (122), first pixel data lines (123), first pixel electrodes (124), first touch drive lines (125), first touch A driving electrode (126), a second touch sensing electrode (127); a dielectric layer (128) and several interconnection columns (129); wherein, one end of the first pixel scanning line (122) is connected to the gate of the TFT element (1211), the other end of which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com