Wire gathering device for brush type connector

A wire take-up device and connector technology, which is applied in the direction of brush manufacturing, etc., can solve the problems of high scrap rate, poor quality, and unsatisfactory collection effect of metal wire segments, etc., and achieve the effect of improving product quality and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific physical embodiments of the present invention.

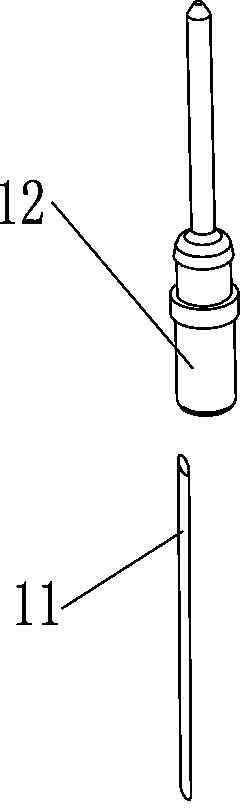

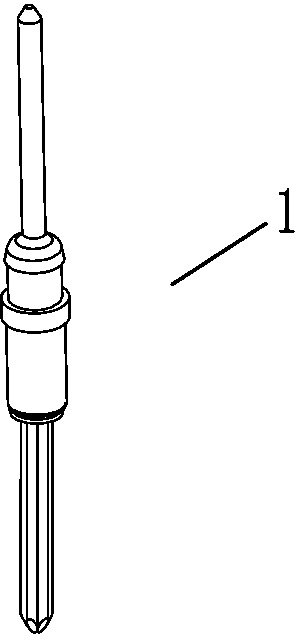

[0033] refer to figure 1 and figure 2 As shown in , the purpose of the present invention is to pull out a roll of continuous wire diameter Φ0.25mm metal wire and cut it into multi-segment metal wire segments 11 of the length required by the brush connector 1. In this embodiment, 7 wire segments are cut each time. After segmenting the metal wire segments 11, gather the 7 metal wire segments 11 into a bunch of metal wire segments, so that the subsequent mechanism can conveniently put on the metal connecting sleeve 12.

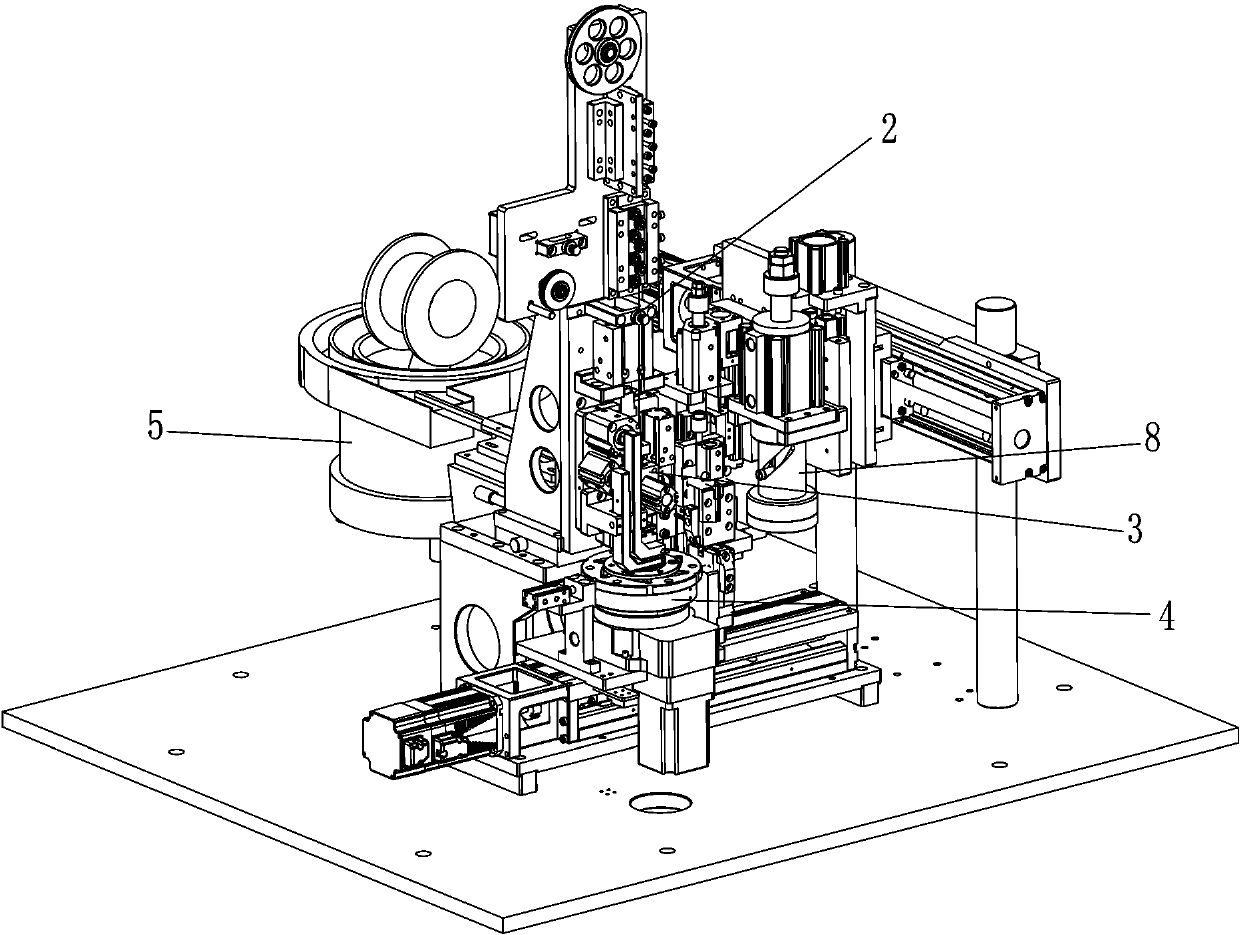

[0034] Such as image 3 and Figure 4 As shown in , the structure of the present invention to realize the above-mentioned purpose automatically includes: a wire releasing mechanism 2 , a wire inserting and cutting mechanism 3 and a wire taking mechanism 4 .

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com