Novel liquid immersion cooling device

A heat sink, liquid immersion technology, applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve problems such as poor flexibility, limited use of liquid immersion systems, and inability to flexibly control liquid immersion temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

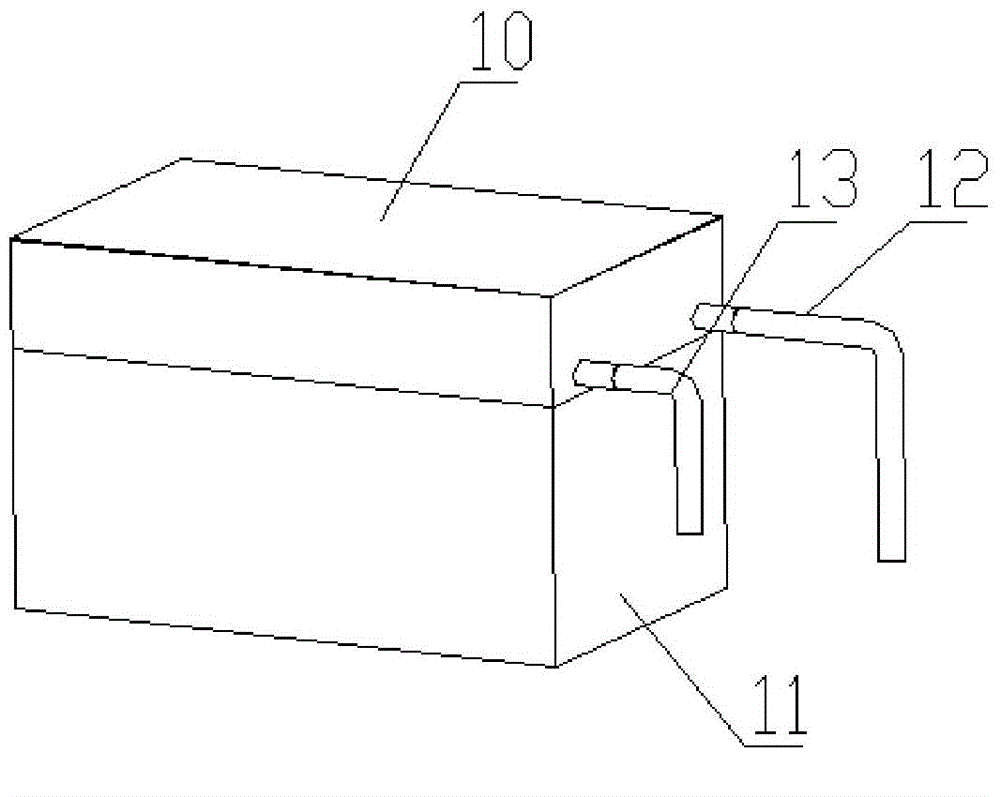

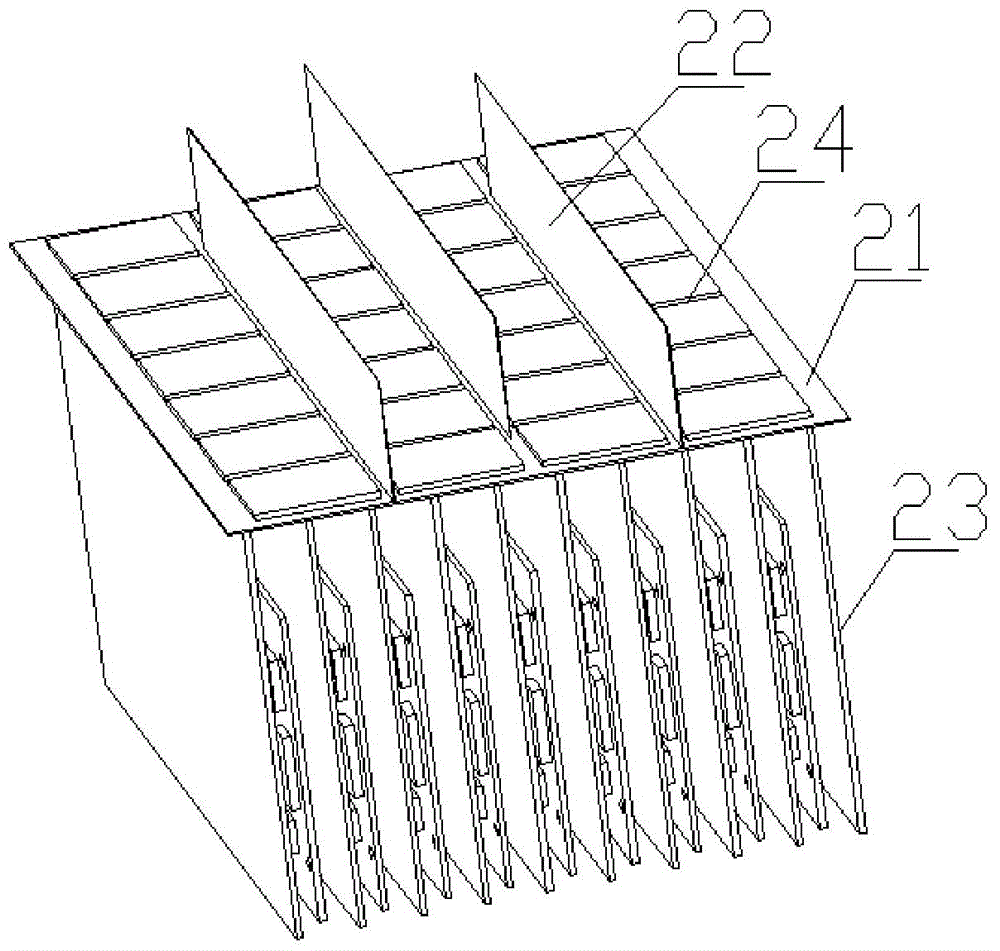

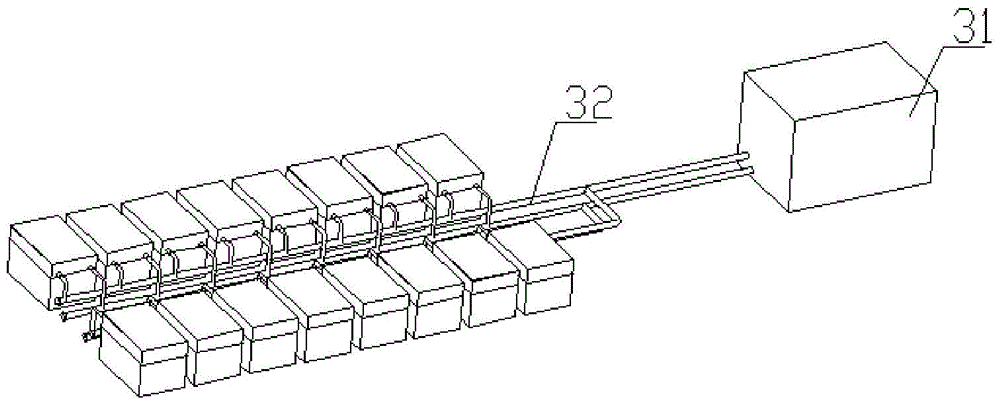

[0020] Several liquid immersion cooling devices provided by the present invention are connected to the chiller 31 through the cooling water pipe 32, and the cooling water enters the liquid immersion cooling device provided by the present invention along the cooling water pipe 32 under the action of the water pump in the chiller 31 The internal circulation of the upper liquid storage bin 10 takes away the heat emitted by the hot surface of the TEC cooling chip 24, which has achieved the purpose of cooling the chips and other electronic devices in the lower liquid storage bin 11. In this way of use, in the outdoor cooling unit, the heated coolant can be further cooled, and this process is continuously circulated, and the heat at the chip can be continuously taken outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com