scroll compressor

A scroll compressor and scroll technology, applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of reduced reliability, reduced efficiency, and reduced performance, so as to prevent performance decline and suppress Effect of reduced reliability, reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

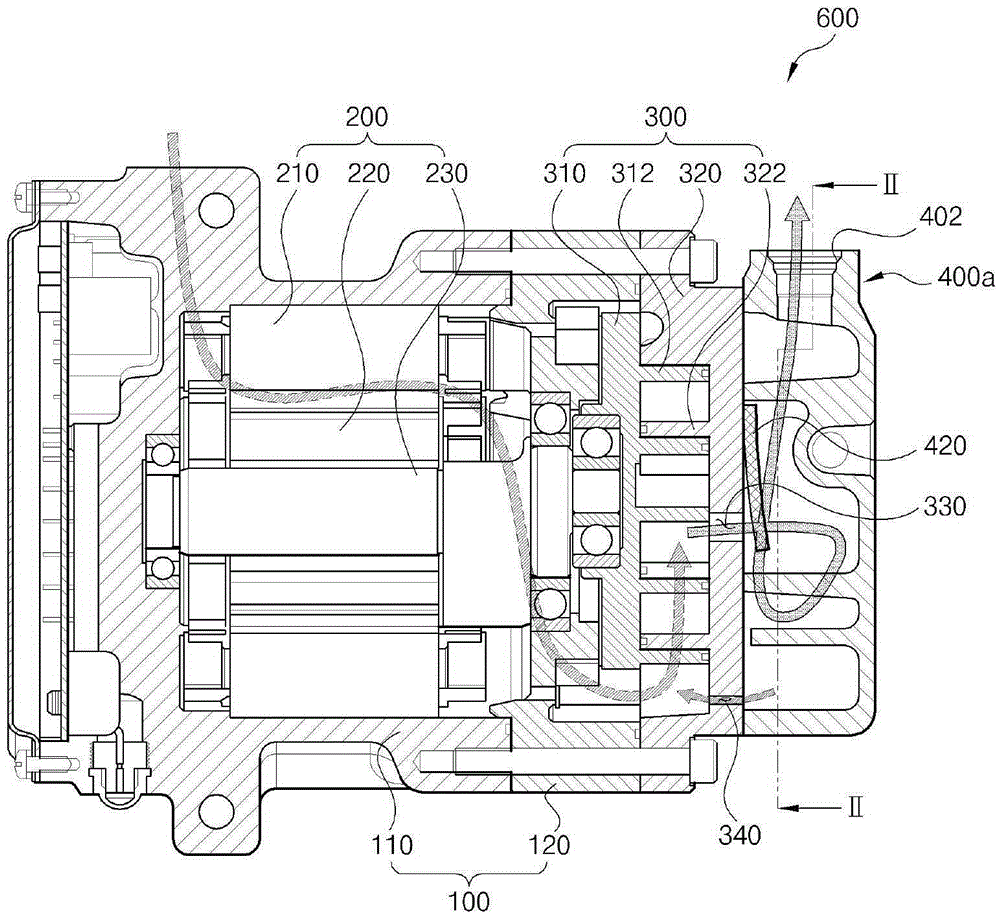

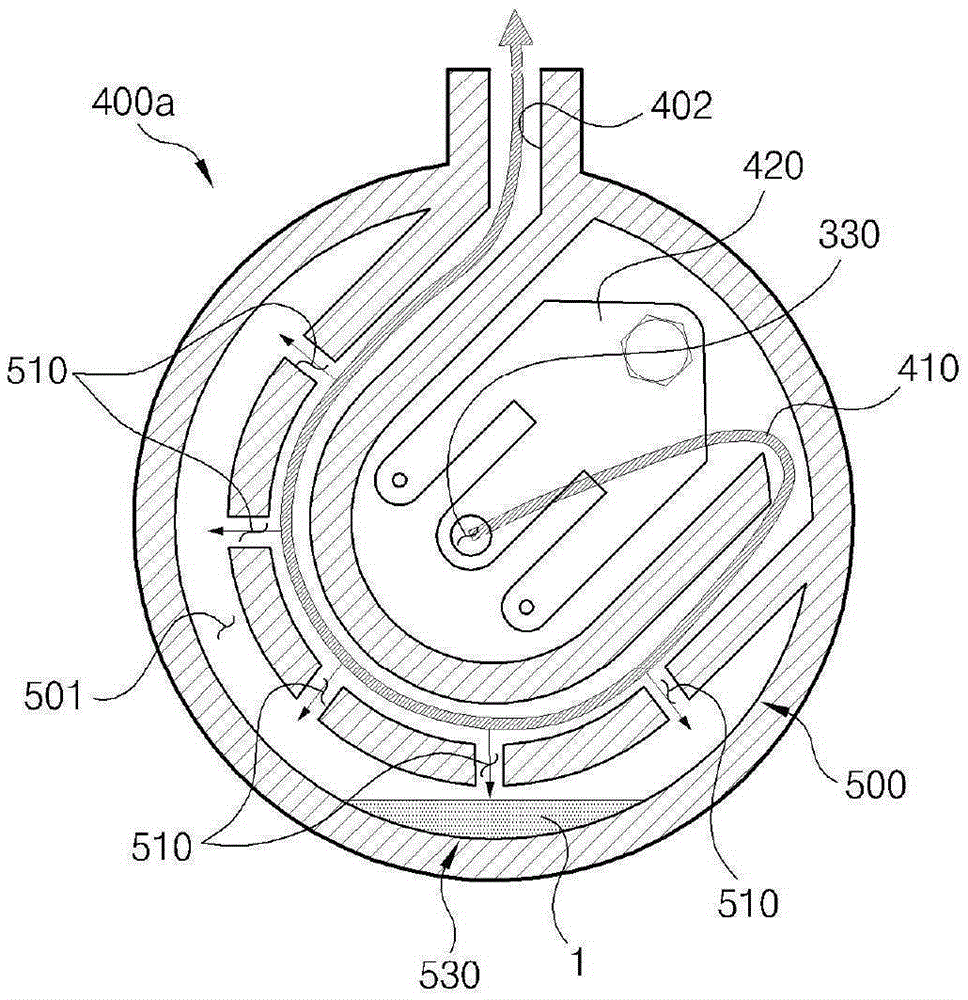

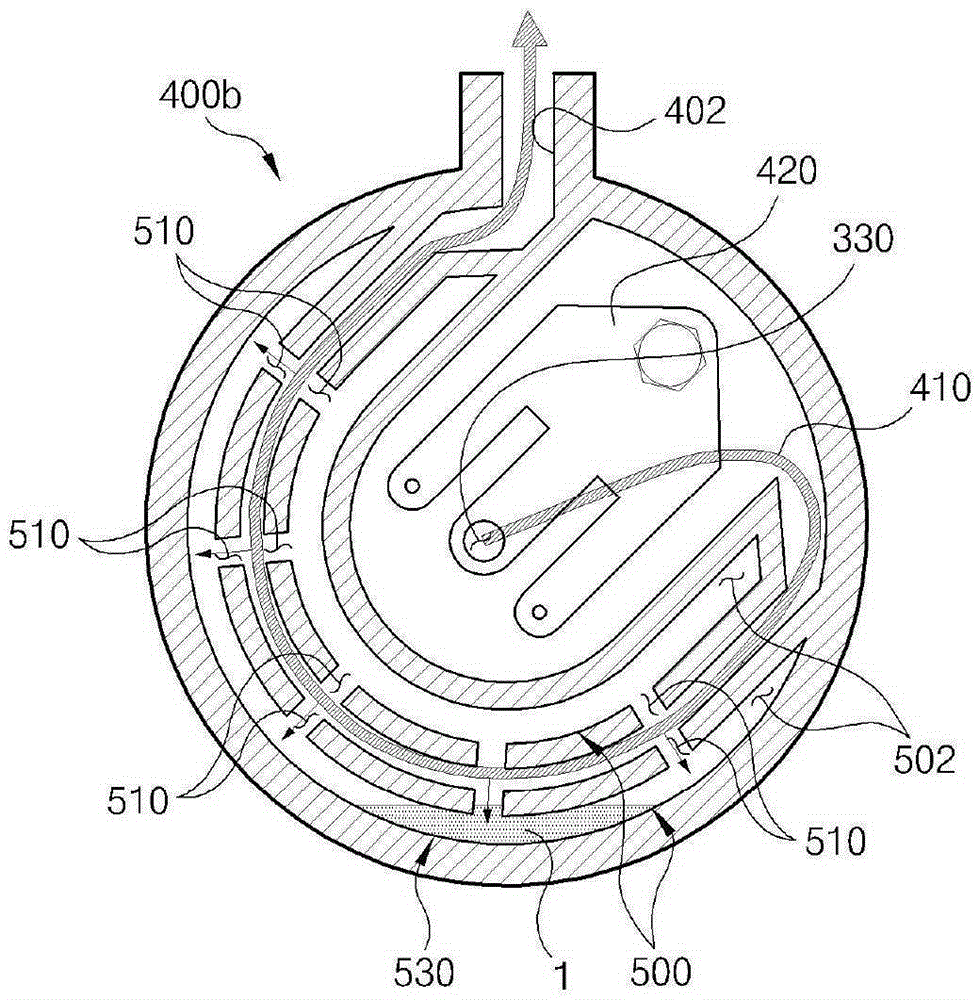

[0023] The present invention relates to a scroll compressor, which includes: a main casing having a suction port for sucking refrigerant from the outside; a driving unit arranged at a side of the main casing. internally and generates torque; a scroll compression unit including an orbiting scroll and a fixed scroll, the orbiting scroll is rotated by torque transmitted from the drive unit and has helical rotating teeth , the fixed scroll is engaged with the main casing to be fixed and has helical fixed teeth meshing with the rotating teeth; and a discharge casing is engaged with the main casing and has An inlet through which high-pressure refrigerant compressed by the scroll compression unit flows into the inside and a discharge port through which the refrigerant flowed into the inside through the inlet is discharged, wherein the discharge casing includes: a discharge passage, the a discharge channel is formed spirally from the inlet and communicates with the discharge port form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com