A spring loaded device

A technology of loading device and loading rod, which is applied in the field of pulverized coal crushing and grinding, can solve the problems of complex hydraulic system, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

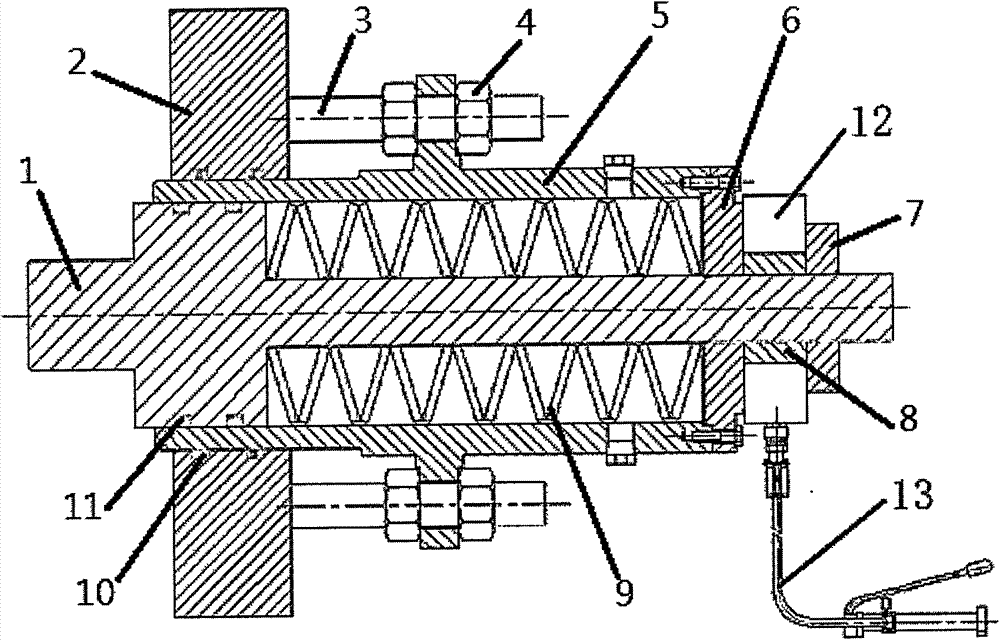

[0017] In order to make the present invention more obvious and understandable, a preferred embodiment is hereby described in detail in conjunction with the accompanying drawings as follows:

[0018] First, according to the extrusion force required when the grinding roller 20 crushes and grinds the raw coal 21 into qualified coal powder, select a suitable disc spring group 9 so that the maximum and minimum working loads of the disc spring group 9 meet the requirements of the grinding roller 20. Requirements. combine figure 1 , first follow the figure 1 Assemble the spring loading device, because the loading force generated by the disc spring group 9 is very large, it is necessary to tighten the loading nut 8 by means of the hydraulic cylinder 12, the hydraulic cylinder 12 is a ring structure, and there are 8 evenly distributed wrenches on the loading nut hole. When tightening, the hydraulic cylinder 12 is set on the outside of the loading nut 8 first, then the lock nut 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com