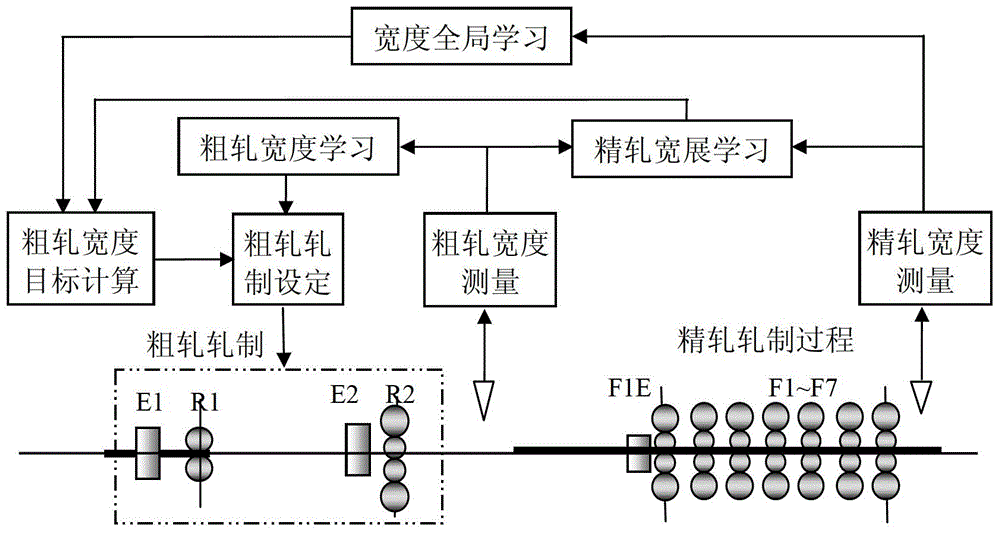

Comprehensive self-adaptive control method of width of rough rolling band steel

A technology of self-adaptive control and self-adaptive calculation, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as difficult optimization learning of dog-bone model, failure of slab to work, difficulty in learning width model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

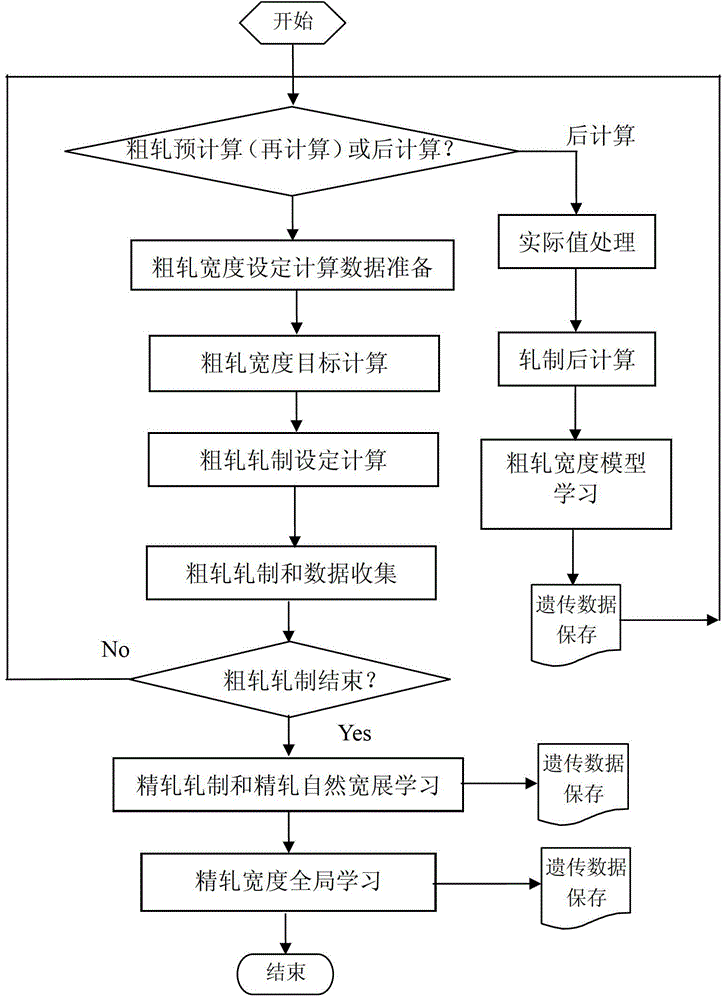

Method used

Image

Examples

Embodiment

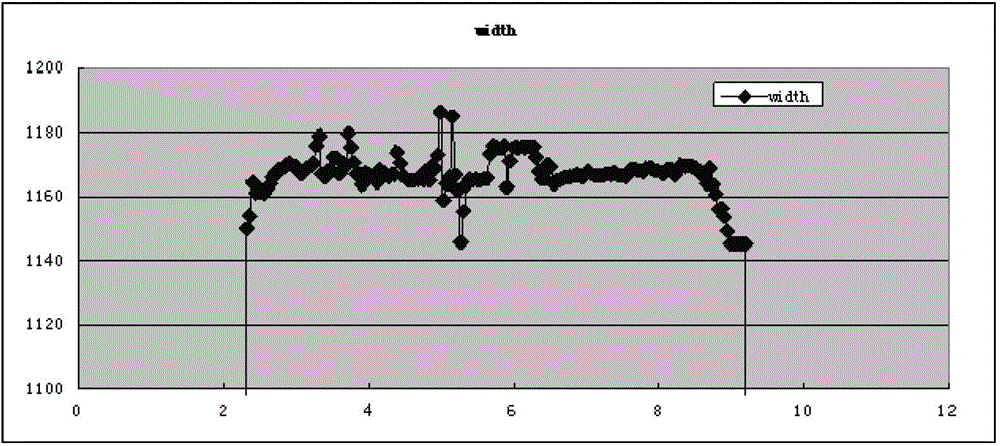

[0221] Strip steel inlet width: Width=1200.0mm;

[0222] Strip finish rolling width target: FMWTarget=1160.0mm;

[0223] E1 roll diameter: E1Diam=800.0mm;

[0224] E2 roll diameter: E2Diam=1190.0mm;

[0225] Rough rolling inlet temperature: 1100°C;

[0226] Incoming material thickness: 230mm

[0227] R1 roll diameter: R1Diam=1300.0mm

[0228] R2 roll diameter: R2Diam=1230.0mm

[0229] Roughing Width Target Calculation

[0230] Calculated value of natural width of finishing rolling: W FMspread =-5.6mm

[0231] Width margin process correction value: MarginTechnic=0

[0232] Basic value of width margin: MarginBase=7.5mm

[0233] Width margin learning value: MarginInher=0mm

[0234] Then Margin=7.5mm

[0235] Effective depression of E3 width: dW E3effect =dW E3 -W E3dog =5.0-4.0=1.0mm

[0236] Rough rolling target width system correction W HMI =0mm

[0237] Width global correction value W Inherglobal =1.5mm

[0238]Then calculate the rough rolling width control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com