Secondary protection small rail car

A rail trolley and secondary protection technology, applied in the direction of railway car body parts, etc., can solve the problem of curtain wall loss and other problems, and achieve the effect of preventing the trolley from falling and having an ingenious and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

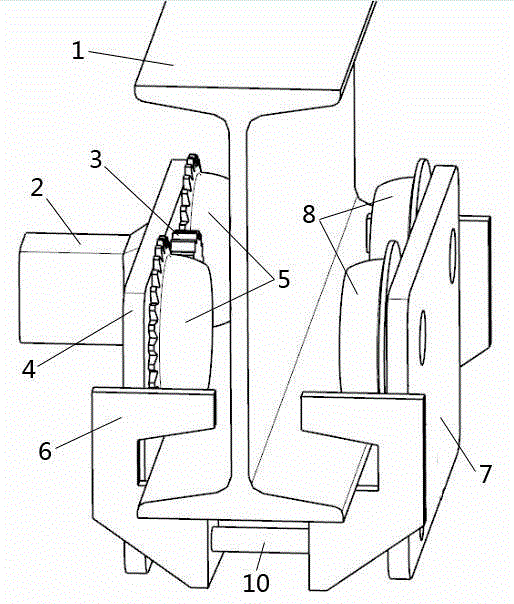

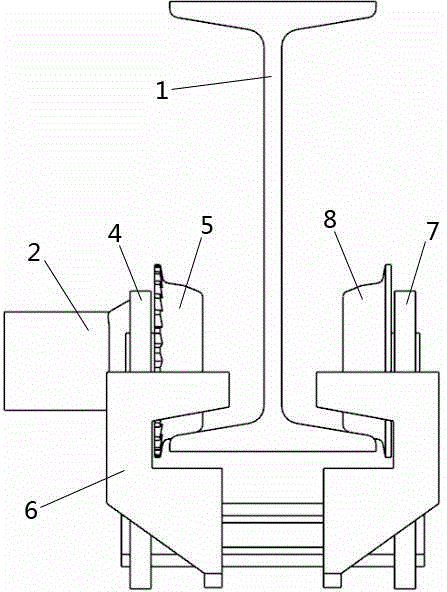

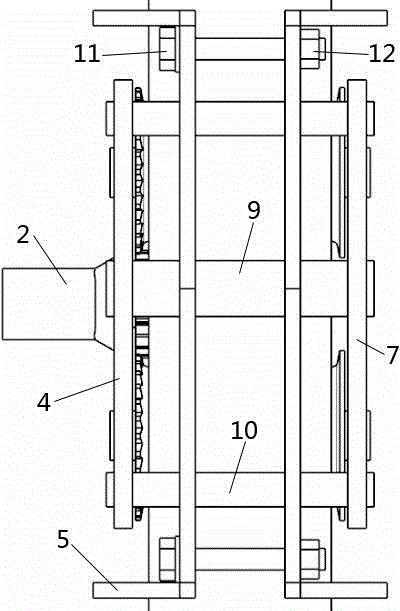

[0011] Such as Figure 1~3 Shown: the present invention mainly consists of I-beam track 1, motor 2, gear shaft 3, driving wheel mounting plate 4, active travel gear 5, secondary protection device 6, driven wheel mounting plate 7, driven traveling wheel 8, crane Head bolts 9, fixing bolts 10, hexagonal bolts 11 and nuts 12; the secondary protection device 6 is connected with the driving wheel mounting plate 4 and the driven wheel mounting plate 7 through bolts; one end of the gear shaft 3 is connected to the motor 2 are connected by a key, and the other end is meshed with two active travel gears 5 through gears.

[0012] For specific applications, such as Figure 1 to Figure 3 As shown, the active travel gear 5 and the driven travel wheel 8 are in contact with the I-beam rail 1, and the motor 2 is connected to drive the gear shaft 3 to rotate through a key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com