Power head guide rail device of heavy drill carriage

A technology of guide rail device and power head, which is applied to supporting devices, drilling equipment, earth-moving drilling, etc., can solve the problems of easy wear and tear of guide rails, short service life of guide rails, poor torsional resistance of guide rails, etc., to ensure accurate positioning and rock drilling. Accuracy, prolonging service life, and reducing the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

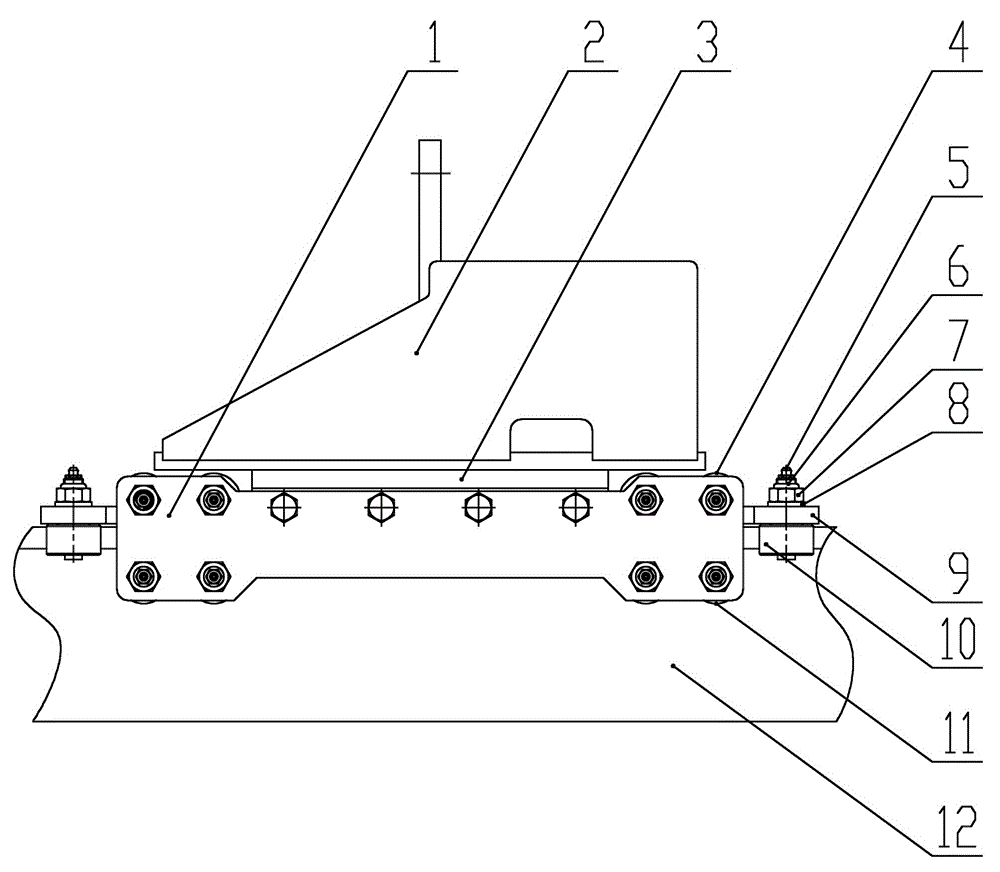

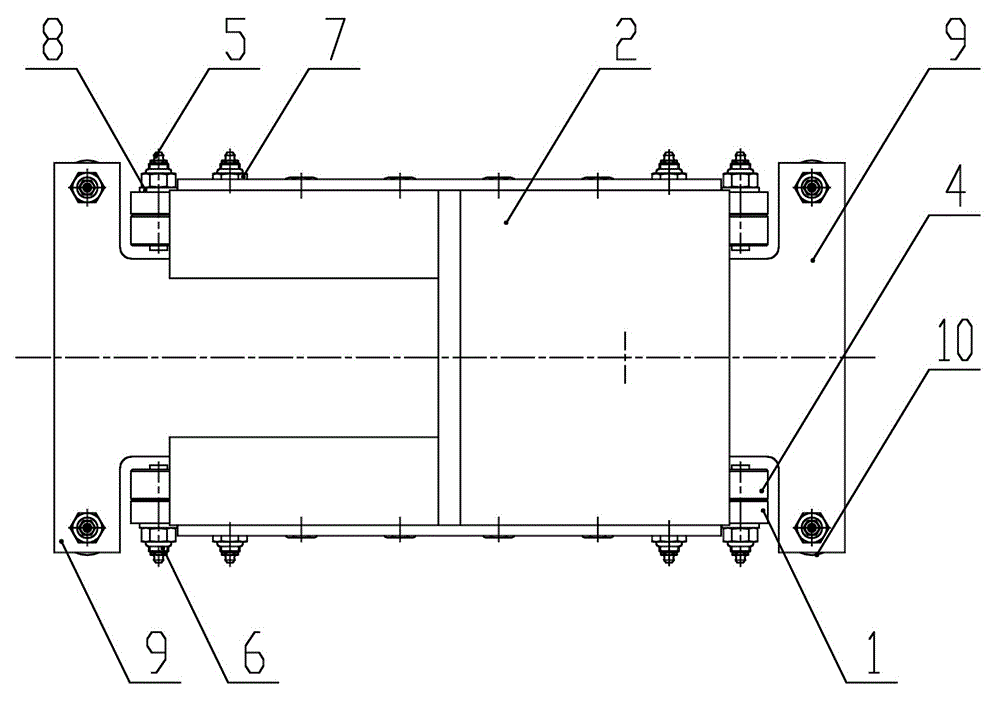

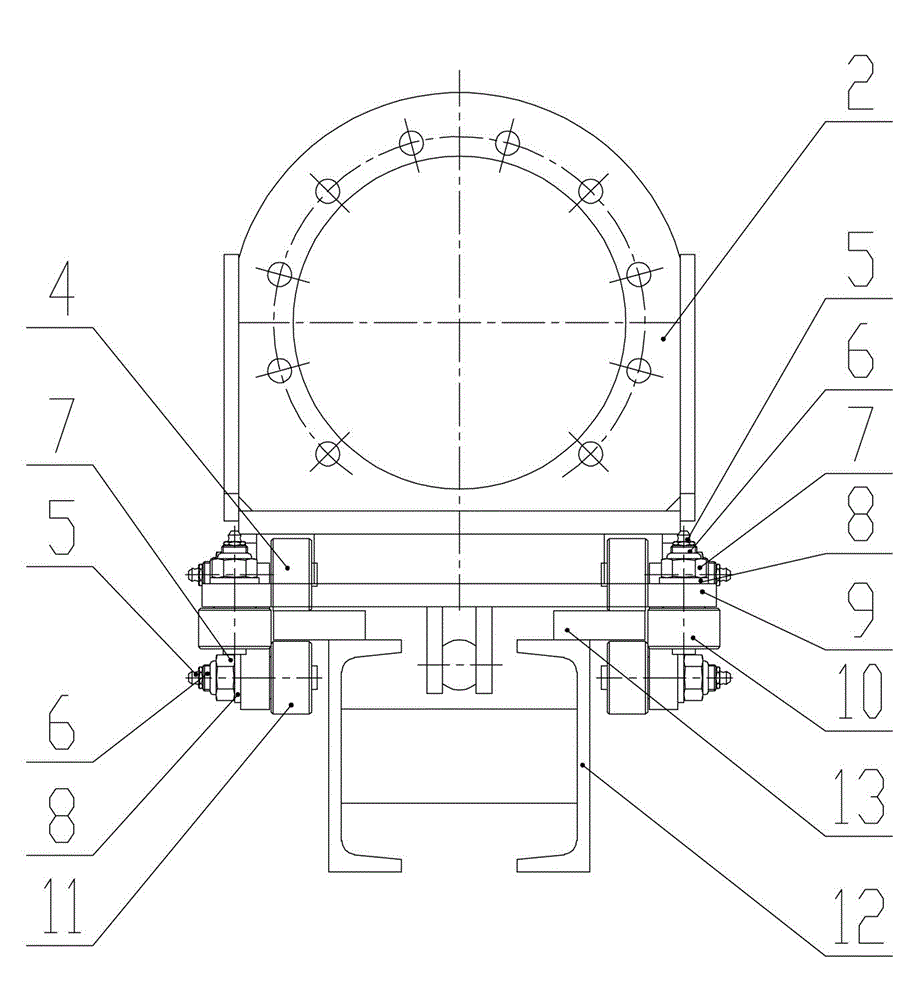

[0015] see Figure 1 to Figure 6 , the present invention includes a guide rail 12, the top of the left and right sides of the guide rail 12 is provided with a guide plate 13 (the present invention describes the structural composition of the guide rail device in terms of the working direction, figure 1 The left and right direction of the guide rail 12 is the working direction, and the left and right sides of the guide rail 12 mentioned here are in the figure 2 The top is reflected as the upper and lower sides), and the guide plate 13 is equipped with a power head fixing frame. The power head fixed frame has a base 2, and the left and right sides of the bottom of the base 2 are provided with connecting blocks 3 arranged oppositely, and a base plate 9 is welded between the two connecting blocks 3, and the front end and the rear end of the base plate 9 protrude outwards respectively. The seat 2 is a T-shaped structure (the present invention describes the structural composition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com