Supporting beam structure for automobile air suspension

A technology of air suspension and support structure, which is applied to suspensions, vehicle parts, cantilevers mounted on pivots, etc. Large coefficient, the effect of reducing bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

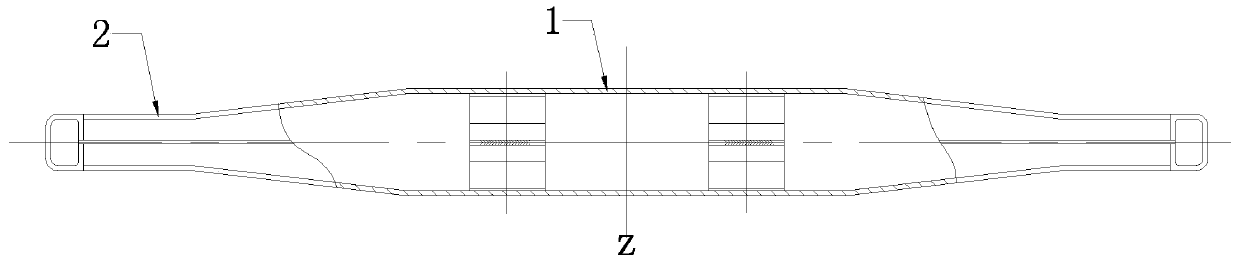

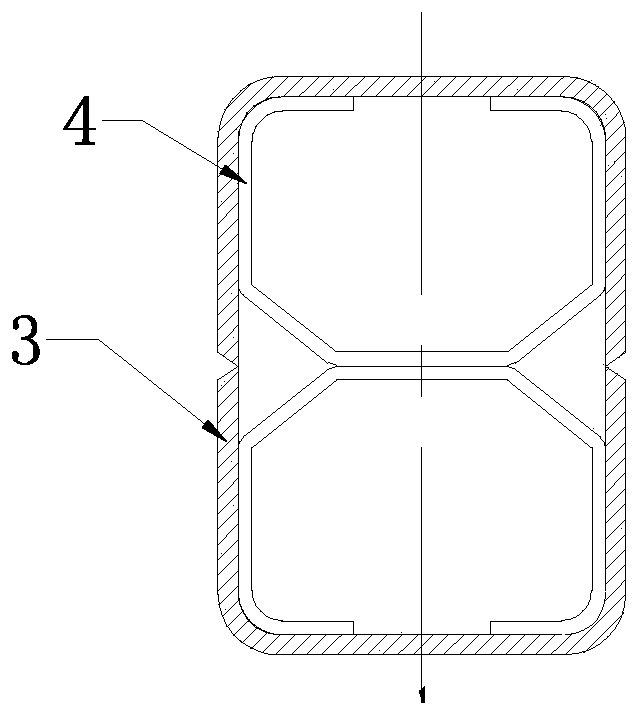

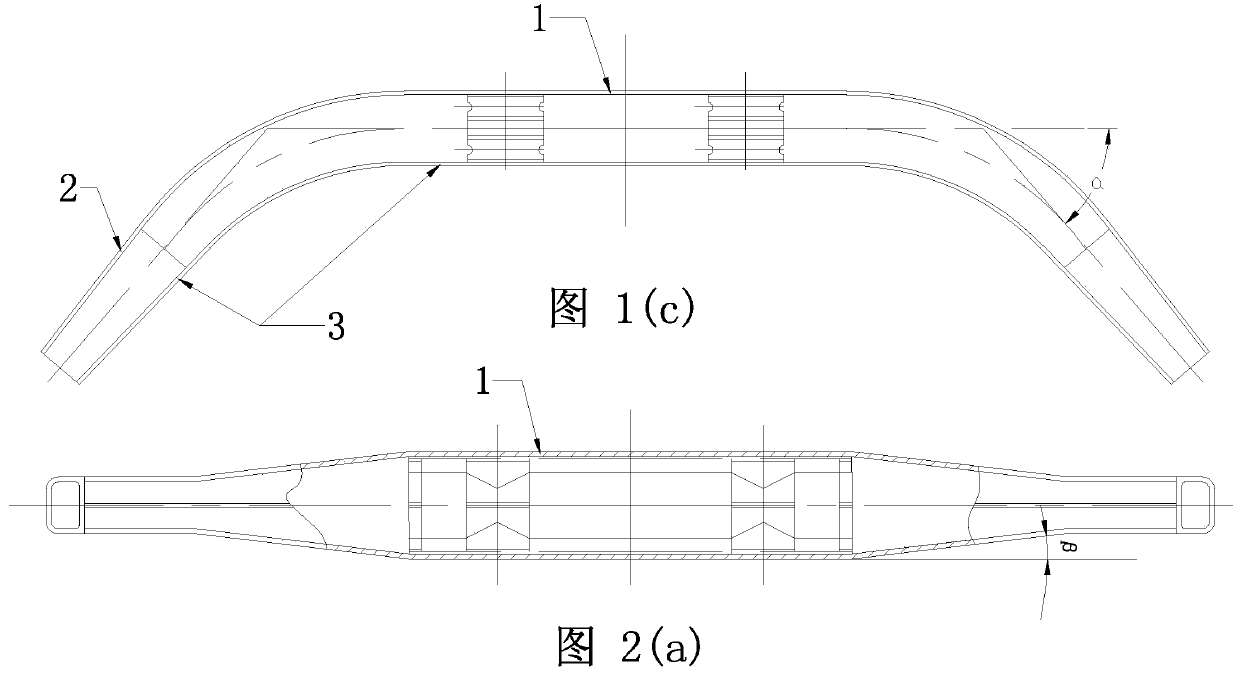

[0074] The support beam structure used for the automobile air suspension in this embodiment is actually a support beam with a split-type reinforced support structure inside the beam body, as shown in Figure 1(a)-Figure 1(c), wherein, In order to make the picture clearer, Figure 1(b) is enlarged at a ratio of 1:3, which includes the central axis section 1 of constant section and the variable section section 2 extending from both sides of the central axis section, the central axis section 1 and the variable section section 2. It has a through-integrated inner cavity, and the variable cross-section section is bent symmetrically along the radial centerline z of the central axis section to form a C-shaped beam structure. The variable section of the included angle forms a C-shaped beam structure. It can be seen from Figure 1 (a) that the C-shaped beam structure is a whole formed by welding the upper and lower halves of the profile, and the central axis section 1 is folded with the va...

Embodiment 2

[0077] The support beam structure used in the automobile air suspension in this embodiment is actually a support beam with a combined reinforced support structure inside the beam body, as shown in Figure 2(a)-Figure 2(c). The supporting frame 4 of the C-shaped structure used in the supporting beam structure of the automobile air suspension of the example is the same as that of the first embodiment, and the difference is that in this embodiment, it is also combined with the supporting frame 4 of the C-shaped structure. A U-shaped piece, that is to say, the support structure is composed of a set of upper support members and a set of lower support members. The upper support member consists of an upper U-shaped piece and an upper support placed in the upper U-shaped piece. The lower support member is composed of a lower U-shaped piece and a lower support frame placed in the lower U-shaped piece. At this time, the outer surface of the upper U-shaped piece is in full contact with the...

Embodiment 3

[0079] As shown in Figure 3(a)-Figure 3(b), in order to make the picture clear, Figure 3(b) has been enlarged at a ratio of 1:3, the support beam used for the air suspension of the automobile in this embodiment The structure is actually a support beam with the same support structure as that of Embodiment 2. It differs from Embodiment 2 only in that the shape of the support beam is different. In this embodiment, the inner surface of the central axis section of the C-shaped beam structure 3 Set as an arched curved surface structure, the middle part of the curved surface arched structure is a straight line segment, and the two sides of the straight line segment are connected with the body of the central axis segment through a curve, as shown in Figure 3 (b), the said inner side The surface refers to the surface where the variable cross-section section 2 extends. The inner side here is only equivalent to the opening direction of the C-shaped beam structure 3, and does not refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com