Rigid frame continuous beam double-layer urban elevated road

An elevated road and rigid frame technology, which is applied to the field of rigid frame continuous beam double-deck urban elevated roads, can solve the problems that the lateral dimension of the bridge pier cannot be too small, the logistics and traffic flow cannot be cleared, and the national economic development is restricted. High force and small landing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

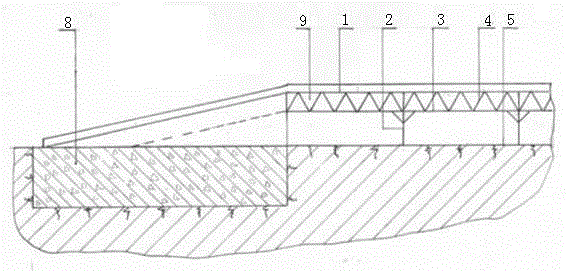

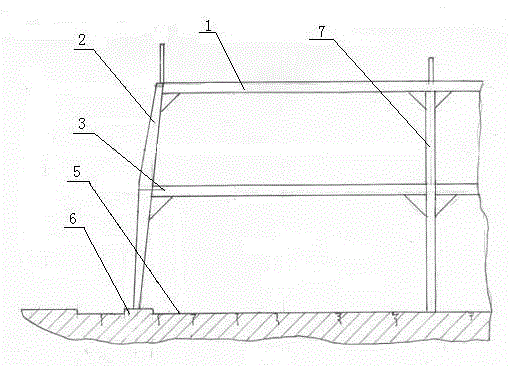

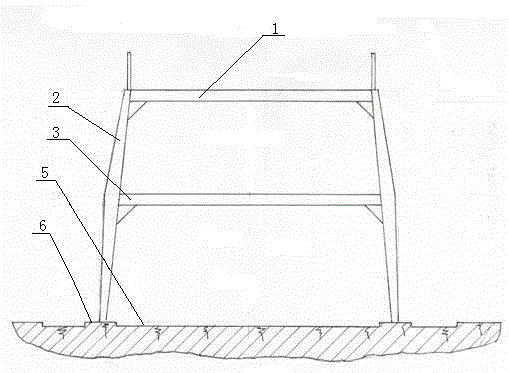

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Accompanying drawing is the specific embodiment of the present invention. This embodiment is a double-layer urban viaduct with rigid frame continuous girders, including a bridge body, continuous girders 9, roadside columns 2 and bridgehead piers 8, and is characterized in that: the bridge body adopts a frame-shaped continuous girder structure, the upper road 1 and the middle layer The road 3 is the upper and lower sides of the frame, and the two sides between the upper road 1 and the middle road 3 form a truss structure with several oblique rods 4, and the roadside columns 2 and continuous beams 9 form a rigid frame structure, and its upper part is large in size and high in bearing capacity. , the lower part size is small and falls on the roadside flower bed 6, does not account for the area of ground road 5. The bridgehead pier 8 is a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com