Novel piezoelectric pump

A piezoelectric ceramic pump and piezoelectric ceramic technology are applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machinery, etc., which can solve the problems of small deformation, low efficiency, and low output flow, and achieve output Effects of increased flow rate and output pressure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

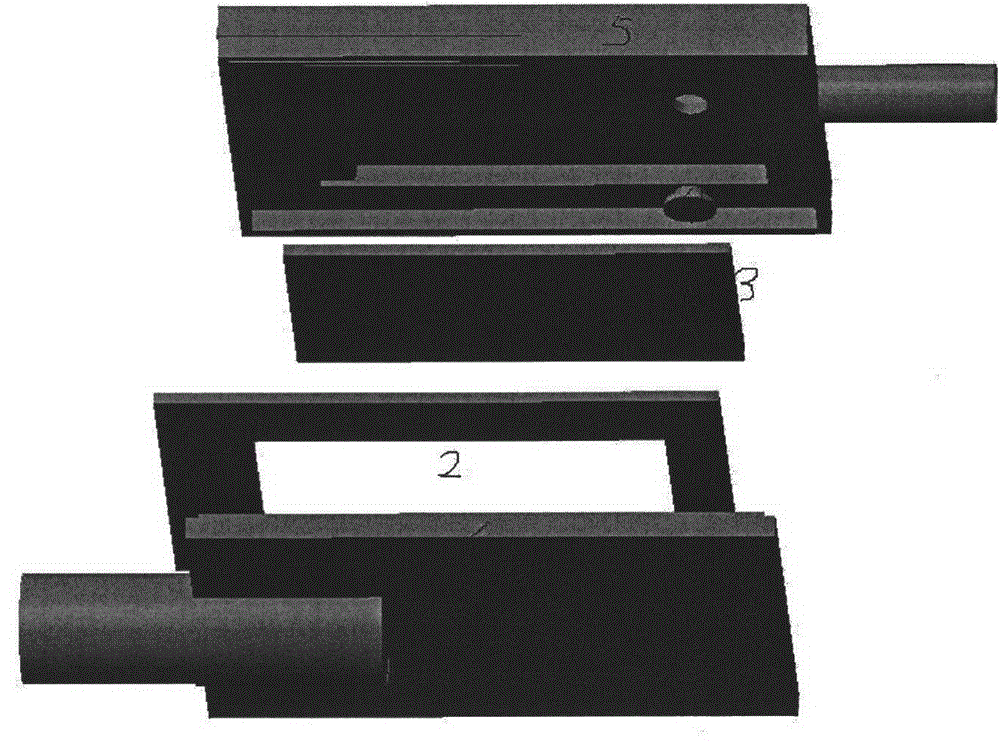

[0014] Square or rectangular pump cavity, square or rectangular piezoelectric vibrator terminal fixed

[0015] figure 2 : 1 Lower housing 2 One-way sealing ring 3 Piezoelectric vibrator 4 One-way valve membrane 5 Upper housing

[0016] The pump casing is composed of upper and lower parts, and there is a square or rectangular groove in the middle of the upper and lower casings. The width of the piezoelectric vibrator piece is smaller than the width of the housing slot, and the length is greater than the length of the housing slot. The one-way sealing ring is sandwiched between the upper and lower housings, and the piezoelectric vibrator piece is located on one side of the one-way sealing ring and is in contact with the one-way sealing ring. The three edges of the piezoelectric vibrator piece maintain a certain gap with the side wall of the groove, and the other side is fixed on the side wall of the groove.

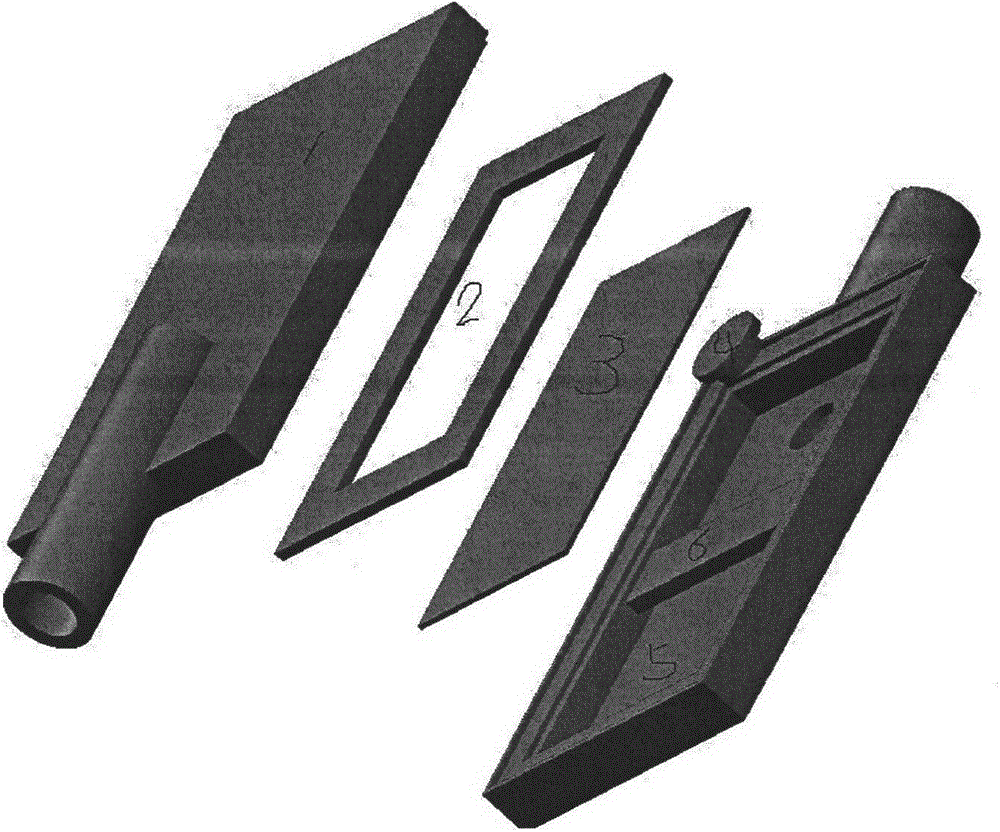

Embodiment approach 2

[0018] Square or rectangular pump cavity, fixed in the middle of square or rectangular piezoelectric ceramics

[0019] The pump casing is composed of upper and lower parts, and there is a square or rectangular groove in the middle of the upper and lower casings. There is a beam in the center of the slot for fixing the piezoelectric vibrator piece. The piezoelectric vibrator piece is smaller than the slot on the casing. The one-way sealing ring is sandwiched between the upper and lower housings, and the piezoelectric vibrator piece is located on one side of the one-way sealing ring and is in contact with the one-way sealing ring. A certain gap is maintained between the edge of the piezoelectric vibrator piece and the side wall of the slot.

[0020] image 3 : 1 Lower housing 2 One-way sealing ring 3 Piezoelectric vibrator 4 One-way valve membrane 5 Upper housing

[0021] 6 piezoelectric vibrator fixed beam

Embodiment approach 3

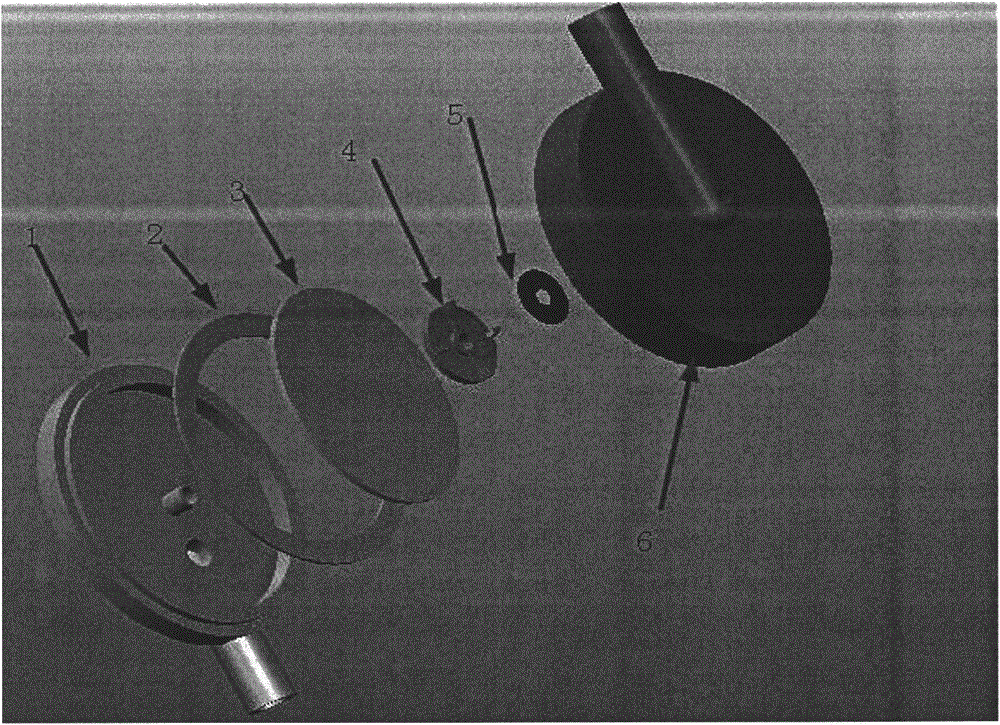

[0023] Circular pump cavity, circular piezoceramic disc, fixed elastic membrane seal at the midpoint

[0024] Figure 4 : 1 upper shell 2 piezoelectric vibrator 3 elastic sealing film 4 one-way valve film 5 lower shell

[0025] The pump casing is composed of upper and lower parts, and there is a circular cavity in the middle of the upper and lower casings. There is an elastic film between the upper and lower shells to divide the cavity into upper and lower parts. The edge of the film is corrugated so that the edge of the film can be fixed between the upper and lower shells and the film itself can vibrate. The piezoelectric vibrator piece is located on one side of the membrane, and its diameter is smaller than that of the cavity. Two one-way valves are arranged on the casing of the cavity on the other side, and the fluid directions are opposite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com