Three-dimensional analysis system and method for product assembly clearance

An analysis system and analysis method technology, which is applied in the field of three-dimensional analysis system for product assembly gaps, can solve the problems of product scrapping, failure to remove, and inability to perform three-dimensional measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

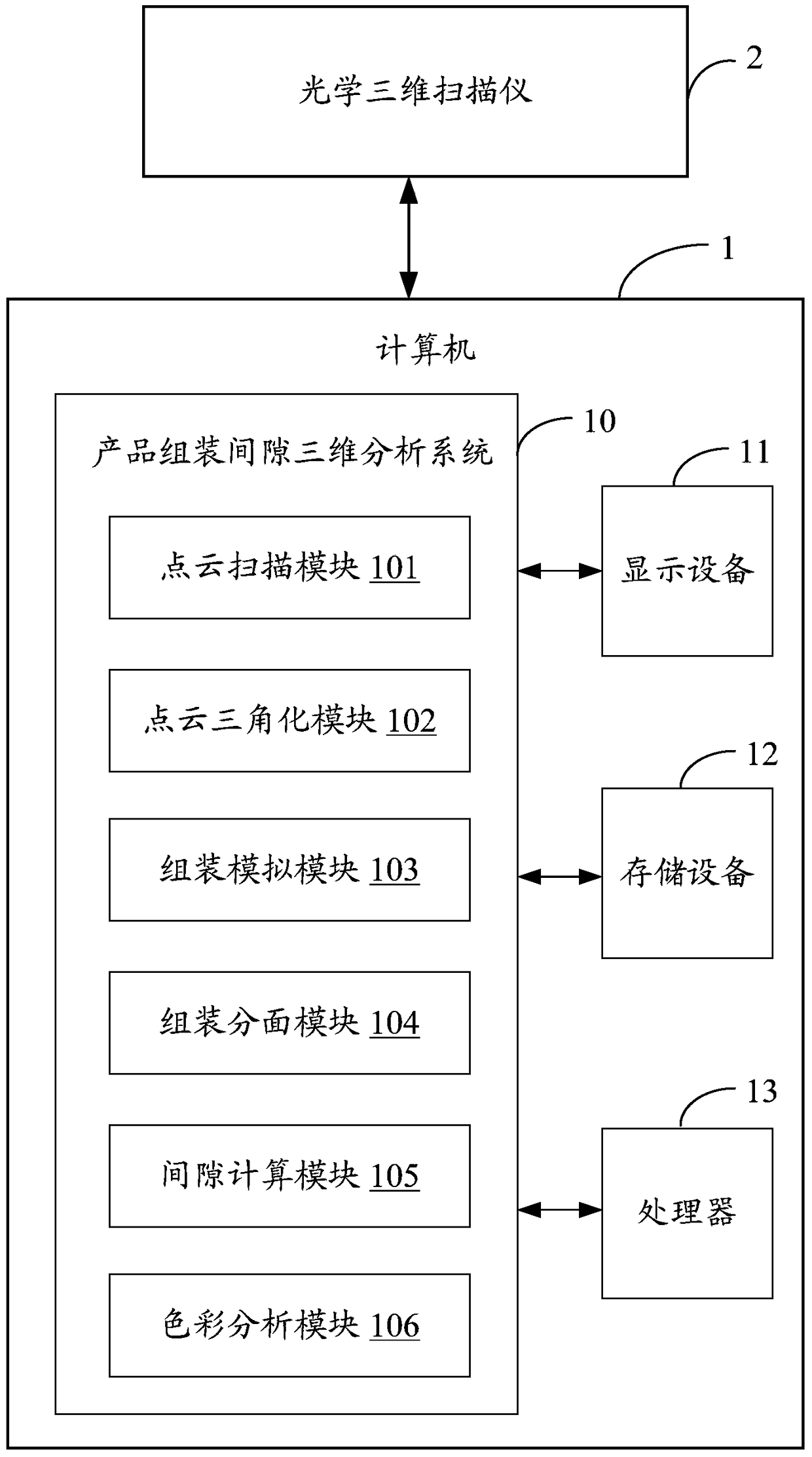

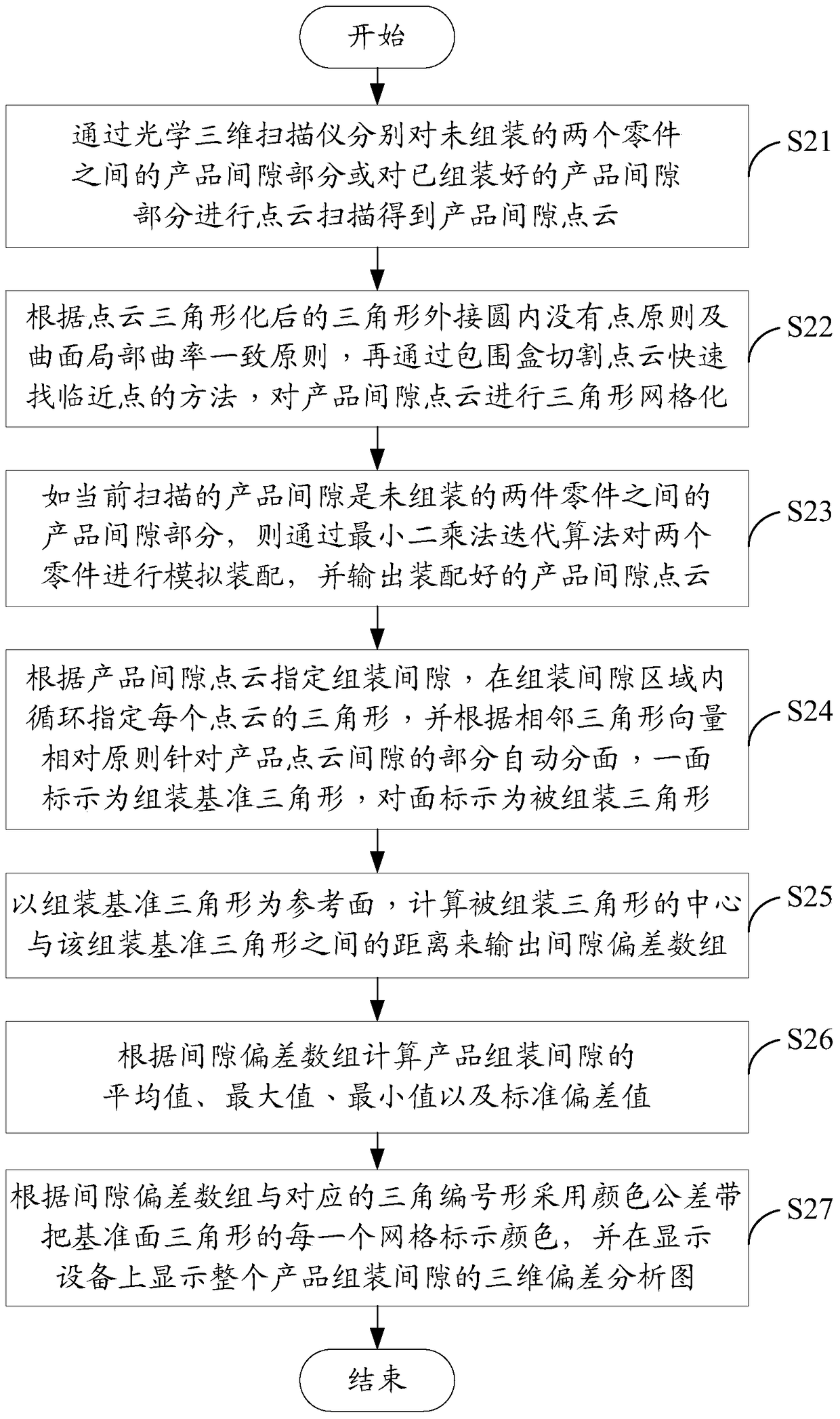

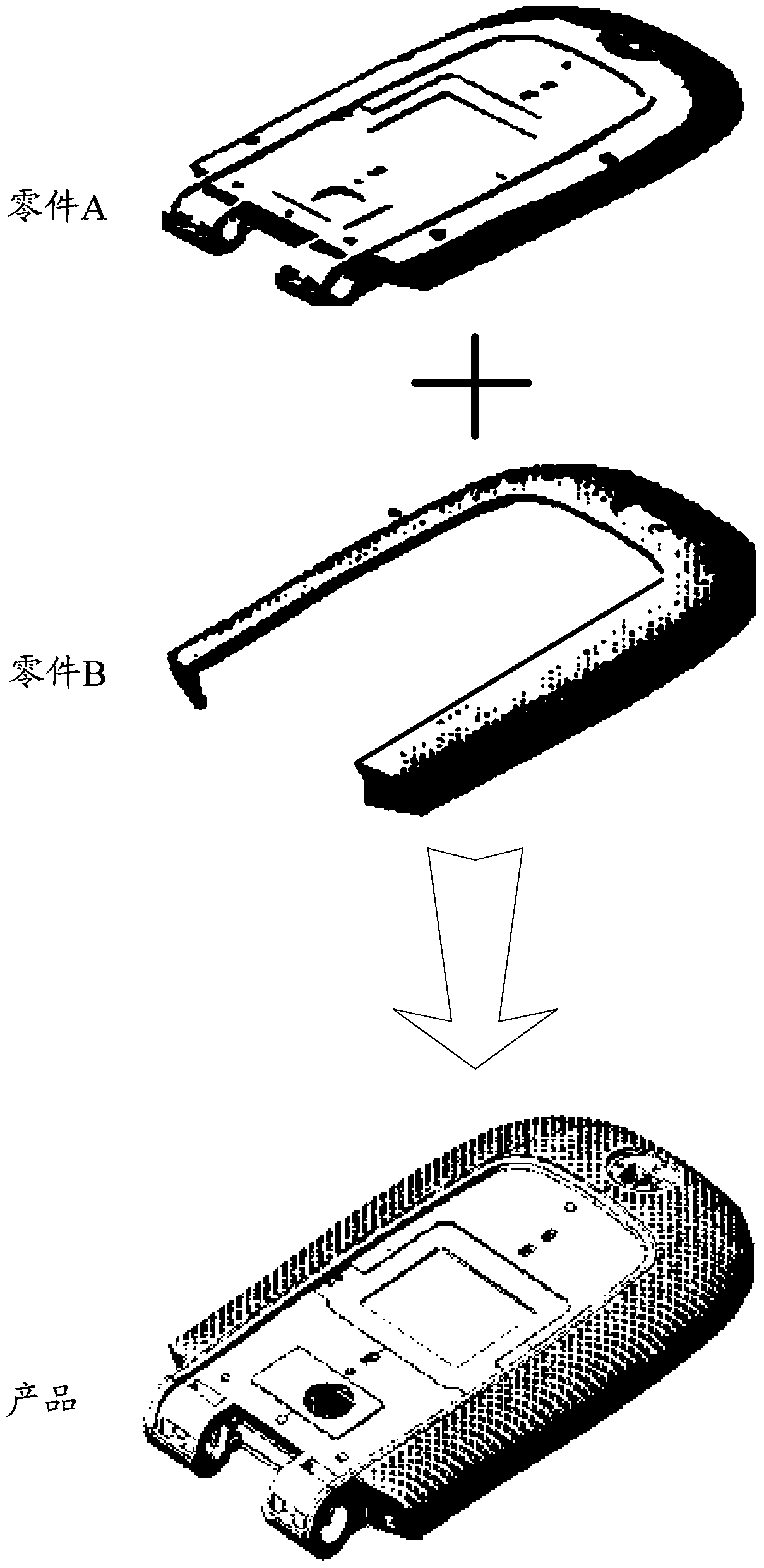

[0026] Refer to figure 1 Shown is a schematic diagram of the operating environment of the preferred embodiment of the product assembly gap three-dimensional analysis system 10 of the present invention. In this embodiment, the product assembly gap three-dimensional analysis system 10 is installed and operated in a computer 1, and the computer 1 also includes, but is not limited to, a display device 11, a storage device 12 and a processor 13. The computer 1 is connected to an optical three-dimensional scanner 2, which is a binocular optical point cloud three-dimensional detection device (charge-coupled device, CCD), which is used to measure the product gap between two unassembled parts Partially or perform point cloud scanning on the gap part of the assembled product to obtain the product gap point cloud. The product assembly gap three-dimensional analysis system 10 calculates the three-dimensional space distance of the product assembly gap according to the product gap point clou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com