capacitor device

A capacitor and capacitor plate technology, applied in the direction of capacitors, multiple fixed capacitors, fixed capacitor terminals, etc., can solve problems such as damage to, hindering the power improvement of electric drive parts of motor vehicles, and aging of capacitor plate stacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

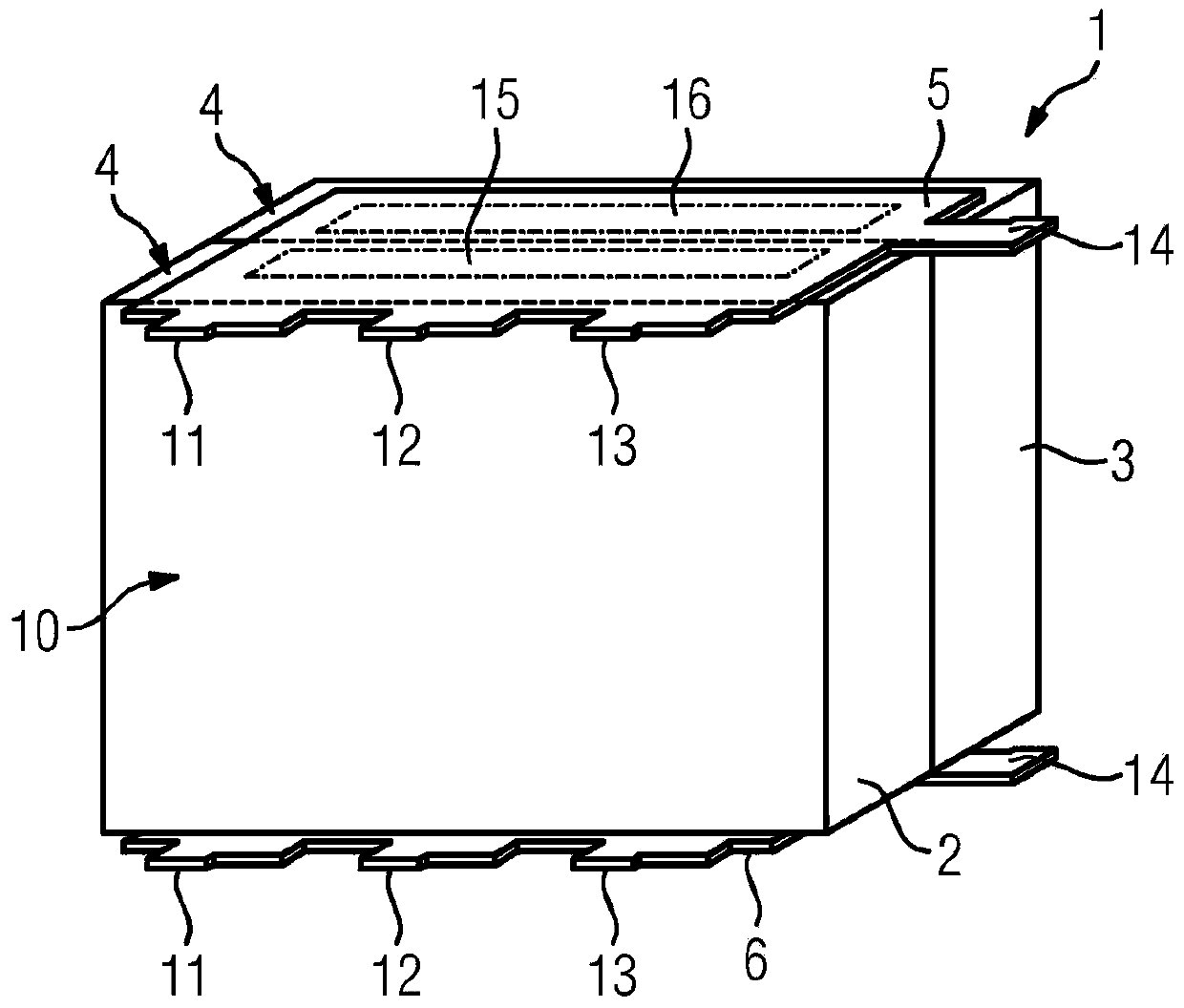

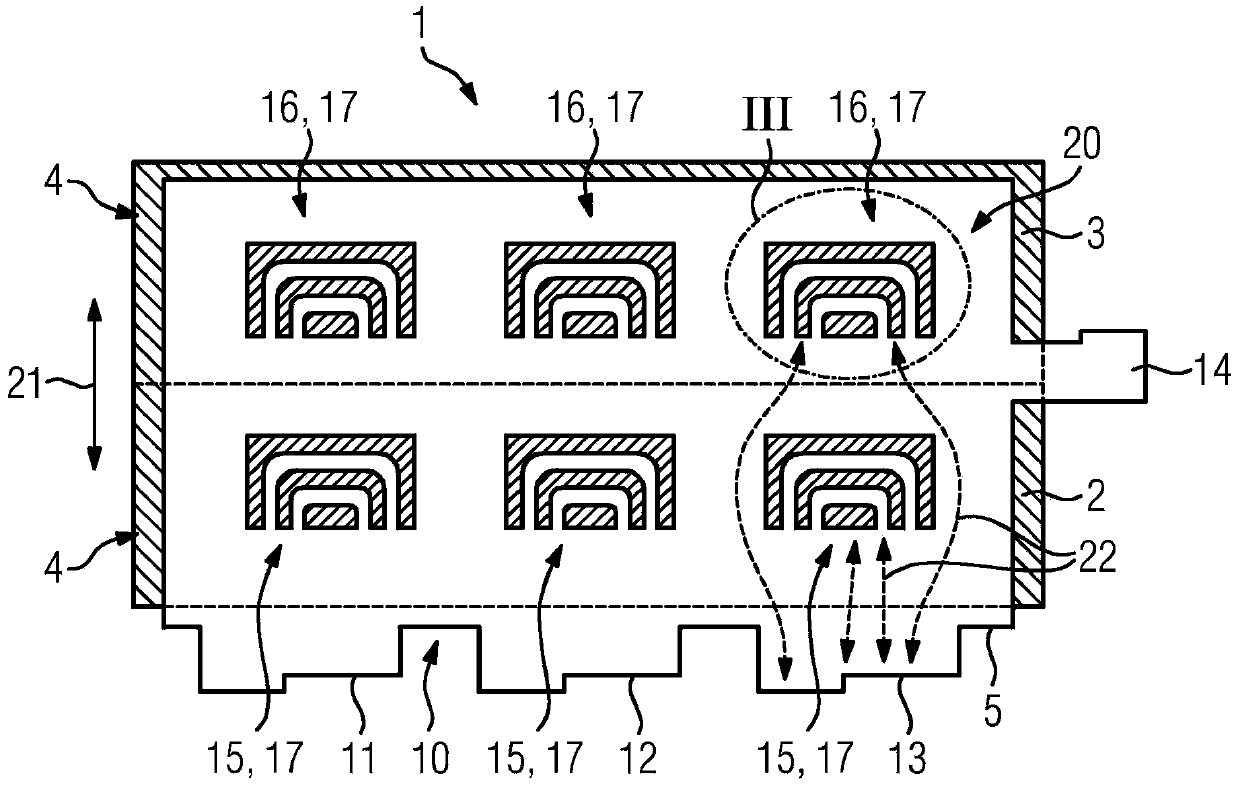

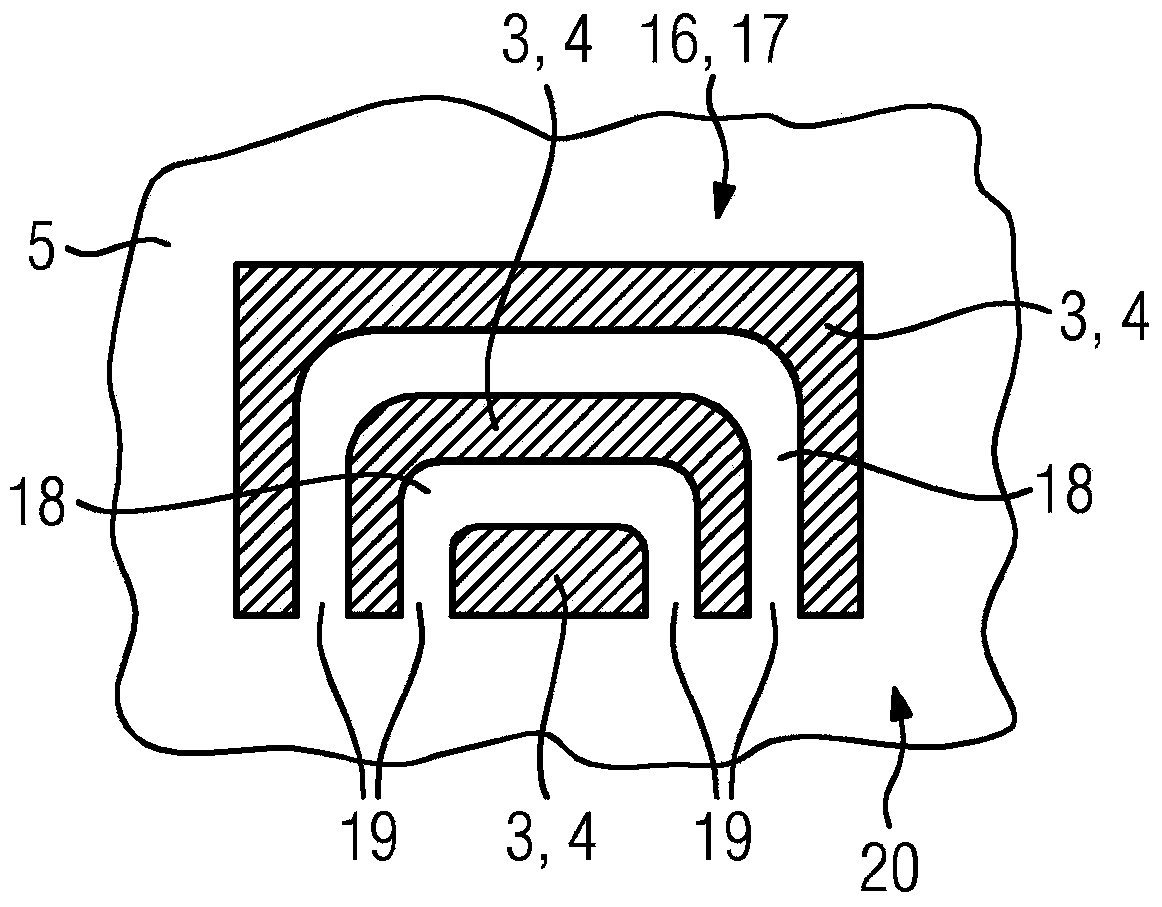

[0033] figure 1 A capacitor arrangement 1 for a (direct current) intermediate circuit of a pulse converter in a drive train of an electric vehicle is shown.

[0034] The capacitor arrangement 1 comprises two capacitor plate stacks 2 and 3 . Capacitor plate stacks 2 and 3 are each a film capacitor, which is conventional per se. Each capacitor plate stack 2 and 3 is formed accordingly from a roll of metallized plastic film, wherein this roll is on both end sides (in accordance with figure 1 are located above and below in the illustration) are metallized to form the connecting surface (hereinafter referred to as Schoob surface (Schoob-Flaechen) 4 ).

[0035] The capacitor arrangement 1 also comprises two busbars for connection to the intermediate circuit, namely a busbar 5 on the high potential side (positive busbar) and a busbar 6 on the low potential side (negative busbar). Each busbar 5 , 6 is formed in each case from a stamped part made of tin-plated copper sheet.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com