Method for automatically cleaning net cage underwater

An automatic cleaning and net cage technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of inconsistent diameter of net clothes, difficulty in moving up and down, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

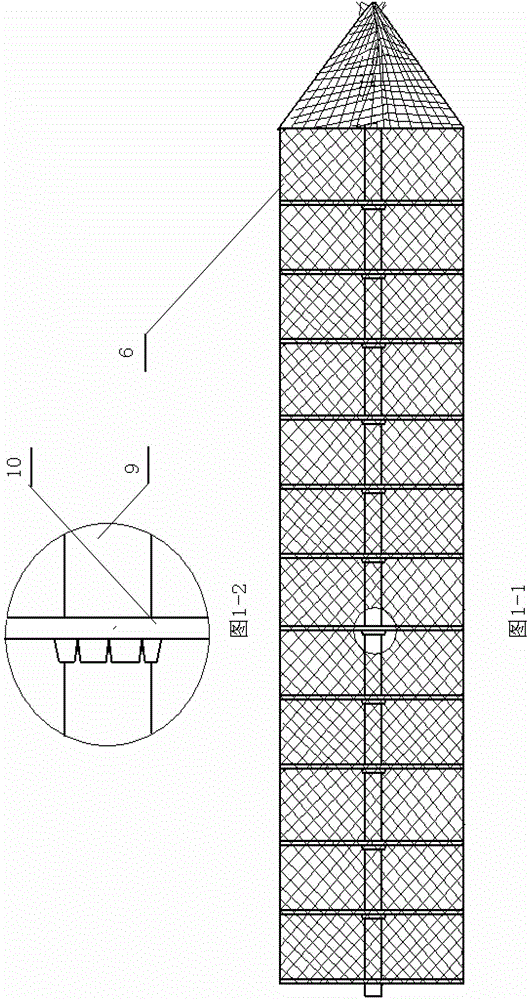

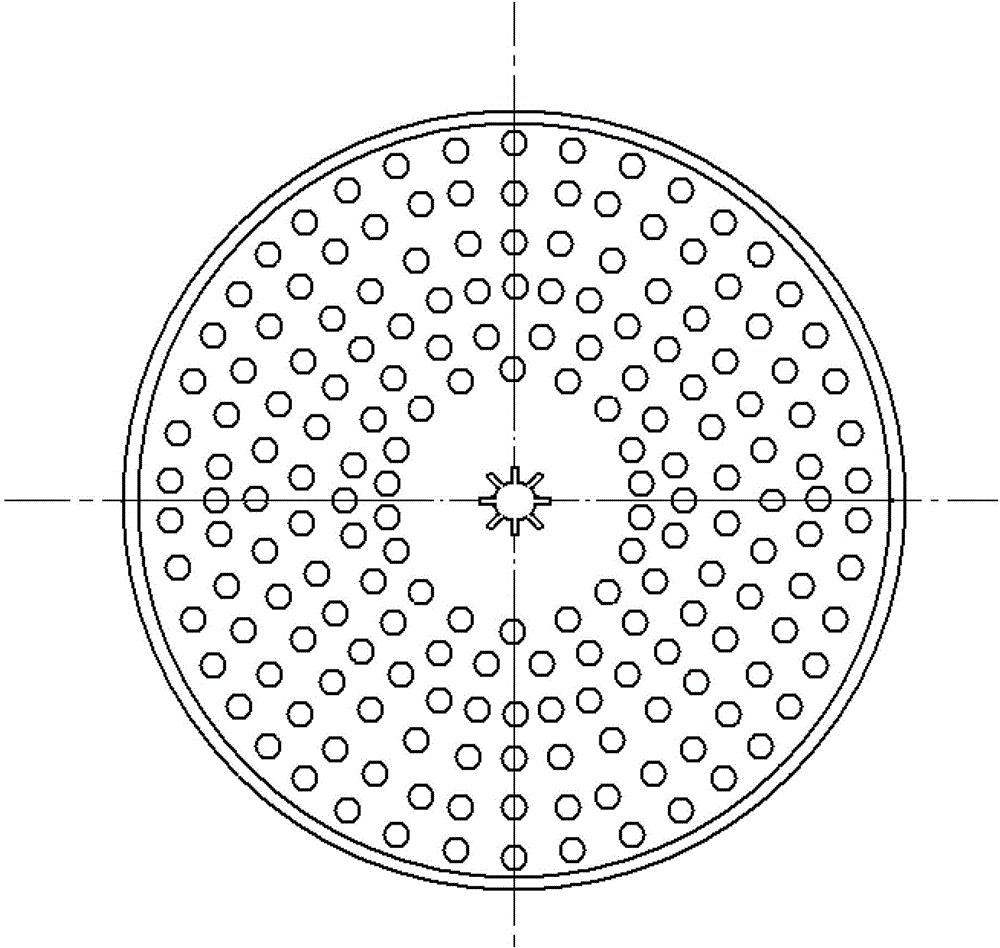

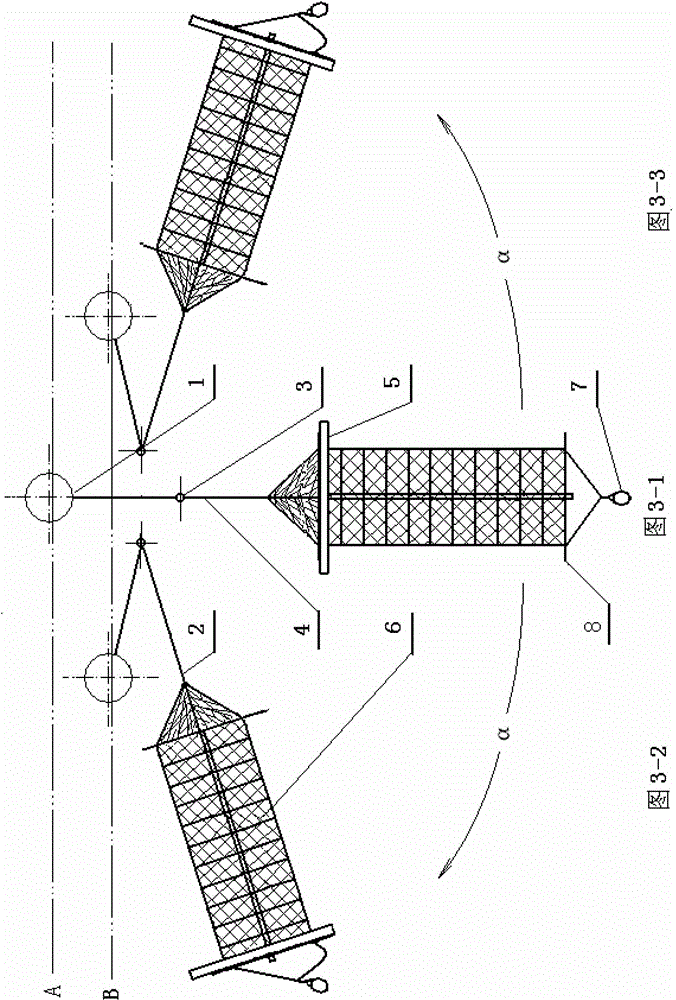

[0010] according to figure 2 Compress or injection mold the cage partition at one time, so that there is a round hole in the center of the cage partition, and there are a number of evenly distributed gaps around the round hole that are equal in length and perpendicular to the round hole. Sewn together to make a mesh cage. When in use, pass the bamboo poles with a diameter larger than the round hole in the middle of the cage through the round hole in the center of each cage partition in turn, and pull the cage until it is in the longest propped up state. Set the net scraper on the net cage, and install steering wheel-shaped positioning rings on the upper and lower partitions of the net cage so that the net scraper cannot leave the net cage up and down. Install a sandbag under the net cage to prolong the time that the net cage hangs on the sea surface. The net cage is connected with the raft body by the suspension rope, and the raft body is connected with the buoyancy ball by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com