Tobacco sheet coating liquid containing natural pigment and preparing method thereof

A technology of tobacco flakes and natural pigments, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of increasing production links, changing the taste of tobacco flakes, and increasing the difficulty of flavoring, so as to reduce production processes, improve appearance, and prepare The effect is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

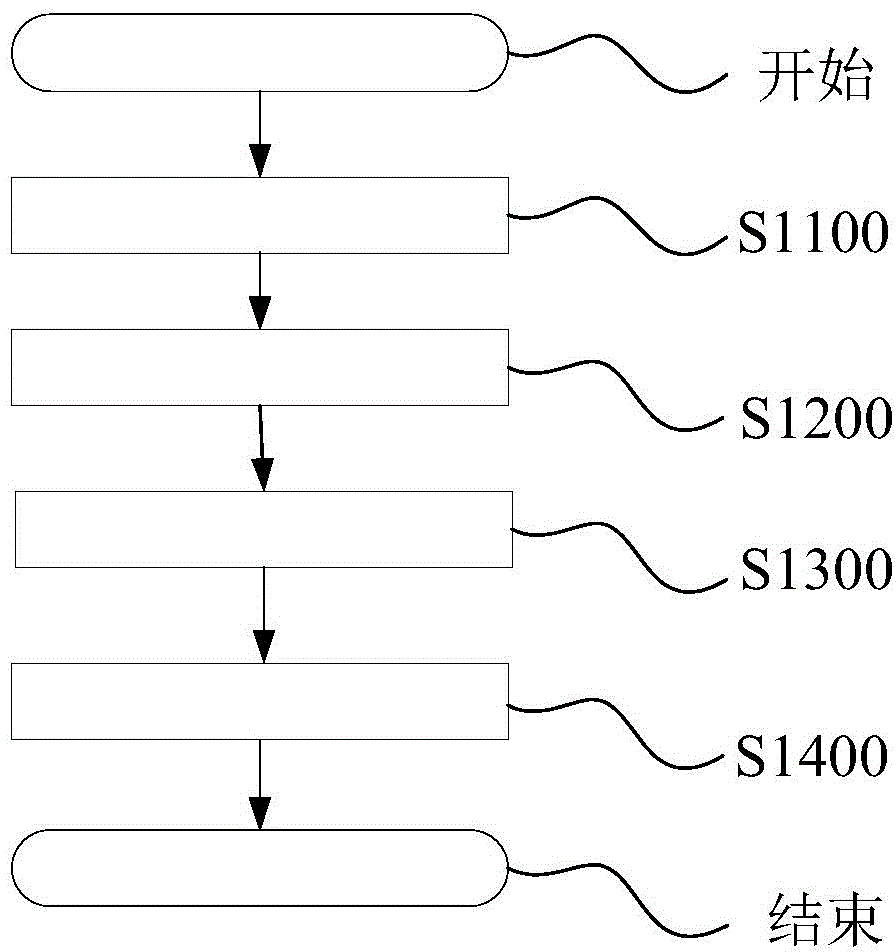

[0025] figure 1 A schematic flow chart showing the preparation method of the tobacco coating solution containing natural pigments of the present invention. Such as figure 1 Shown, the preparation method of this tobacco sheet coating liquid, comprises the steps:

[0026] Primary extraction step S1100: Extract 10-50 parts by weight of the raw material of the appearance improving agent with an extraction solvent to obtain an extract A;

[0027] Secondary extraction step S1200: Dilute the extraction solution A with the extraction solvent to form a diluted extraction solution A, and use the diluted extraction solution A to extract 60-120 parts by weight of tobacco fragments and / or tobacco stems to obtain an extraction solution B ;

[0028] Concentration treatment step S1400: Concentrate the extract B to a density of 1.0-1.5g / cm 3 ;

[0029] Wherein, in the primary extraction step S1100, it is preferable to pulverize the raw material of the appearance improving agent into a pow...

Embodiment 1

[0044] Weigh 50 kg of dried gardenia fruit and 600 kg of tobacco leaf fragments, crush the dried gardenia fruit to a powder with a particle size of less than 10 mm, and crush the tobacco leaf fragments to a powder with a particle size of less than 1.5 mm. Place the crushed dried gardenia fruit in 500kg of water, heat at 40°C, stir and extract for 3 hours, and obtain the extract A containing the appearance improving agent. Add 5000 kg of water to the above extract A to obtain 5400 kg of diluted extract A, put the crushed tobacco leaf fragments in the diluted extract A, heat at 60°C, and stir for 2 hours to obtain mixed extract B. Concentrate the above extract B in vacuum at 45°C until the density is 1.1g / cm 3 Left and right, the tobacco sheet coating liquid is obtained.

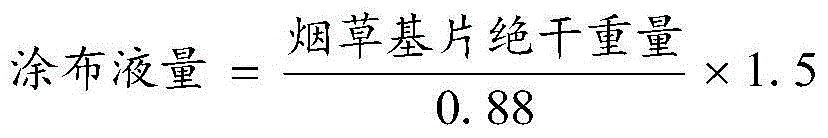

[0045] Based on the weight of the tobacco sheet coating liquid, the coating liquid is diluted with 1.4 times of water, and then saturately coated on the paper-making tobacco sheet by a rolling coating method....

Embodiment 2

[0047] Weigh 100 kg of dried gardenia fruit and 1200 kg of tobacco leaf fragments, crush the dried gardenia fruit to a powder with a particle size of less than 10 mm, and crush the tobacco leaf fragments to a powder with a particle size of less than 1.5 mm. Put the crushed dried gardenia fruit in 500kg of water, heat at 70°C, stir and extract for 0.5h, filter to obtain the extract A1 containing the appearance improving agent and dried gardenia pomace; add 500kg of water to the dried gardenia pomace, heat at 70°C , stirring and extracting for 0.5h, and filtering to obtain the extract A2 containing the appearance improving agent. The extracts A1 and A2 were mixed to obtain the extract A. Add 5200 kg of water to the above extract A to obtain 6000 kg of diluted extract A, put the pulverized tobacco leaf fragments into the diluted extract A, heat at 40°C, and stir for 2 hours to obtain mixed extract B. Concentrate the above extract B in vacuum at 45°C until the density is 1.1g / cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com