a cupping device

A cupping device and tank body technology, which is used in suction containers, suction devices, physical therapy, etc., can solve the problems of tank body deformation, troublesome operation by operators, and difficult to accurately control, and achieve precise adjustment of strength and high one-way valve. Switching efficiency, strong negative pressure adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

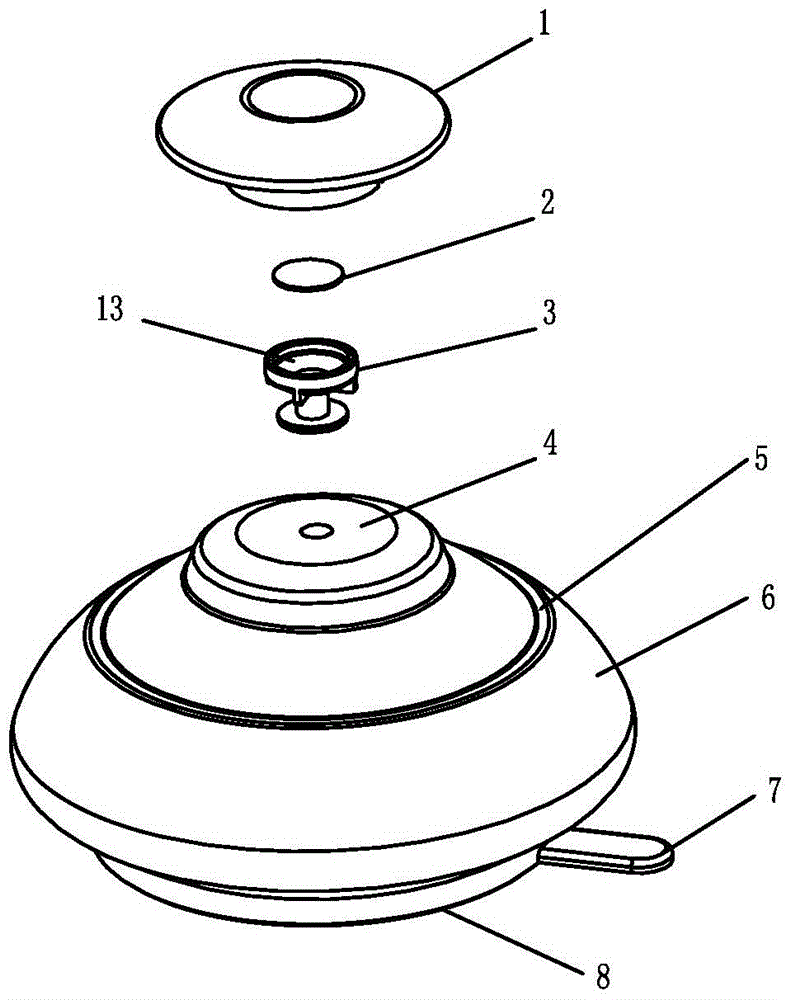

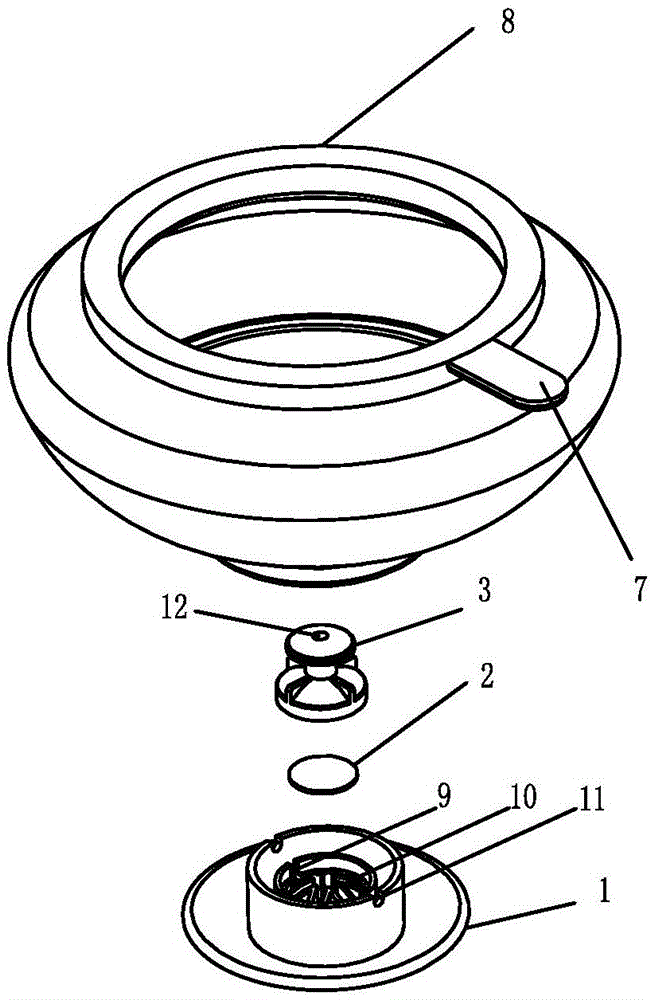

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , the cupping device includes a silicone tank body 6 with a tank bottom 4 and an open tank mouth 8, and the tank body 6 of the cupping device is provided with a one-way air valve that can only be exhausted outside the tank.

[0018] Such as figure 2 , 3 , as an optimized solution, the one-way air valve is arranged at the bottom 4 of the cupping device, and a valve cap 1 is arranged outside the one-way air valve. Further, the one-way air valve includes a valve body 3, a sealing sheet 2, and a support frame 10 arranged sequentially from the inside to the outside of the tank, the sealing sheet 2 covers the valve body 3, and the support frame 10 is connected to the The outer surface of the sealing sheet 2 is in contact.

[0019] Such as Figure 4 , for the above embodiments, the support frame 10 is provided with a bonnet 1 outside, or the support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com