Ceramic substrate ultrasonic cleaning device

A technology for cleaning devices and ceramic substrates, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as affecting the cleaning effect, and achieve improved production efficiency, less contact surface, and better cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

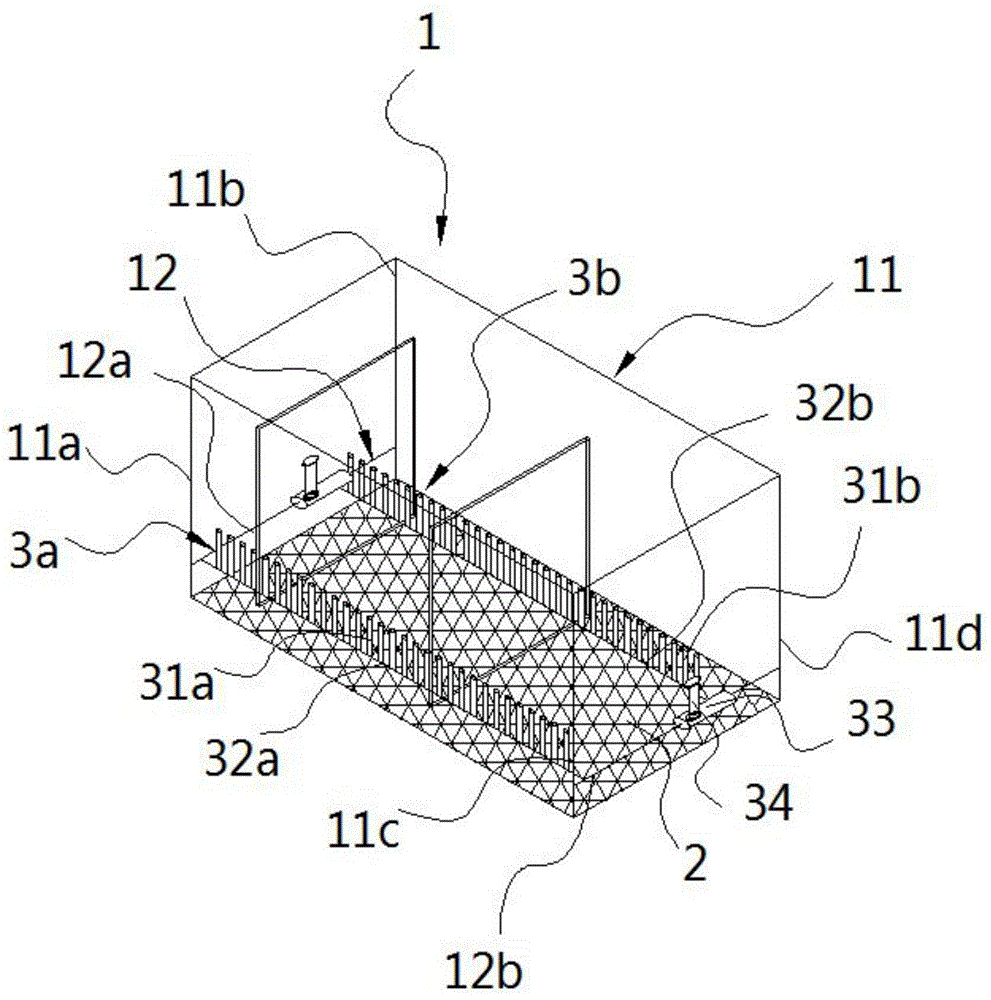

[0011] The ceramic substrate ultrasonic cleaning device of the present invention includes: an ultrasonic cleaning machine and a cleaning frame that can be placed in the ultrasonic cleaning machine, the cleaning frame includes a side frame body 1 and a first slot provided on the side frame body 1 for inserting a substrate 3a, the second slot 3b.

[0012] Such as figure 1 As shown, the side frame body 1 is seamlessly welded by twelve stainless steel columns 11 with a diameter of 6mm, and the twelve stainless steel columns 11 form a cuboid structure. In addition, the stainless steel columns with a diameter of 5mm are used as sliding rods 12a , the two ends are vertically welded to the stainless steel columns 11a and 11b respectively, the stainless steel column with a diameter of 5mm is used as the sliding rod 12b, and the two ends are respectively vertically welded to the stainless steel columns 11c and 11d, due to the seamless welding, the integrity is good, very It is firm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com