Bending device for full-automatic welding machine for volume control piece

A fully automatic welding and volume control technology, which is applied in manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of low production efficiency, manpower consumption, and increased processing time, so as to improve production efficiency, reduce personnel operations, shorten The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

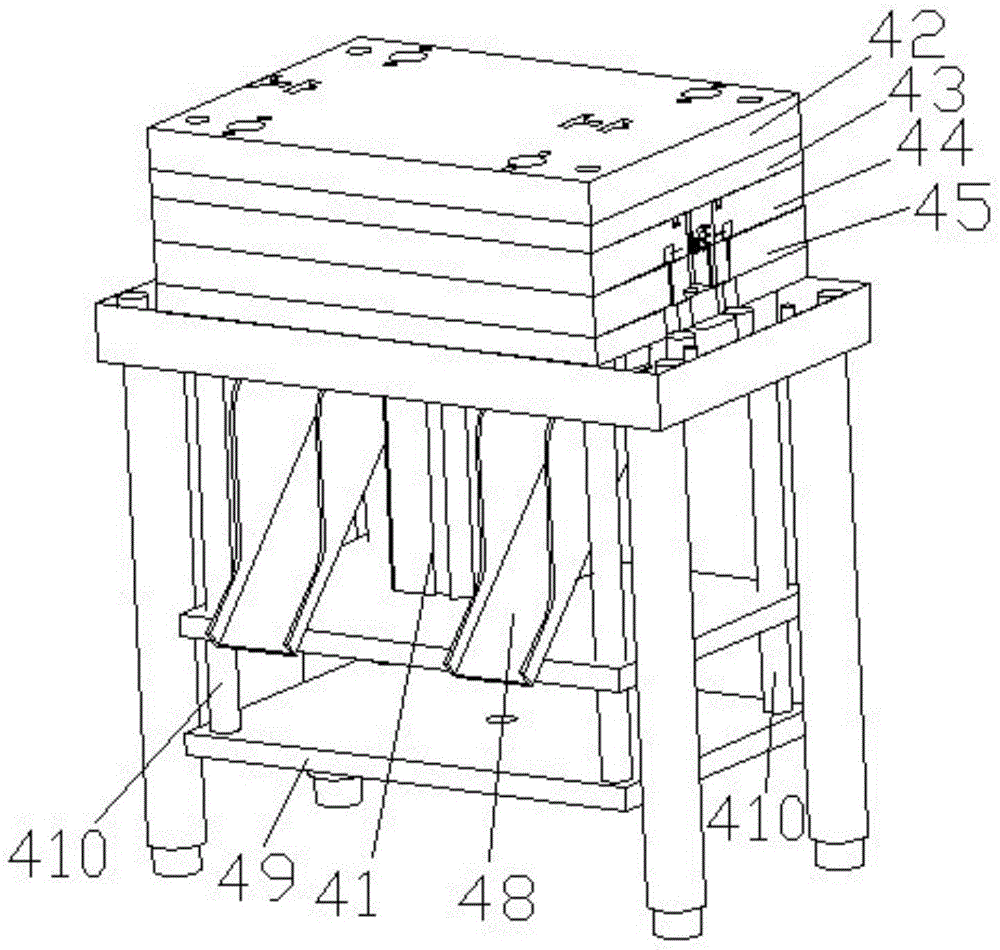

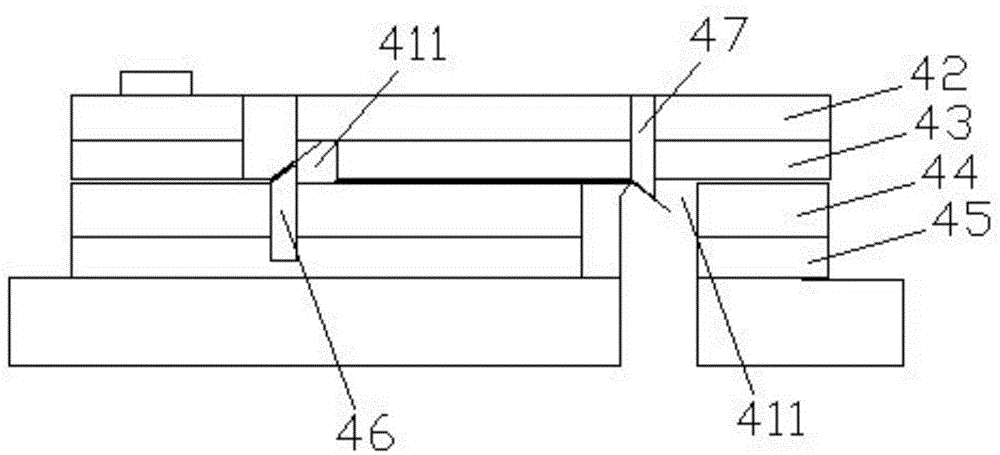

[0014] attached figure 1 It is the bending device used for the automatic welding machine of the volume control part according to the present invention, which includes a bending upper and lower driving device 41, a bending splint 42, a bending upper die 43, a bending stripping plate 44, and a bending lower die 45. Bending lower punch 46, bending upper punch 47, bending slide plate 48, top plate 49 and bending guide column 410; the bending splint 42, bending upper die 43, bending stripper 44 and the bending lower die 45 are stacked sequentially from top to bottom, the top plate 49 is connected to the bending splint 42 through the bending guide column 410, and the upper end of the bending lower punch 46 is a sharp angle inclined upward at 45°, so The lower end of the bending upper punch 47 is a sharp angle inclined downward at 45°, and the bending lower punch 46 and the bending upper punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com