Cutting device for full-automatic welding machine for volume control piece

A technology of automatic welding and cutting device, applied in the field of cutting device, can solve the problems of low production efficiency, labor consumption, processing time increase, etc., and achieve the effect of improving production efficiency, reducing personnel operation, and shortening processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

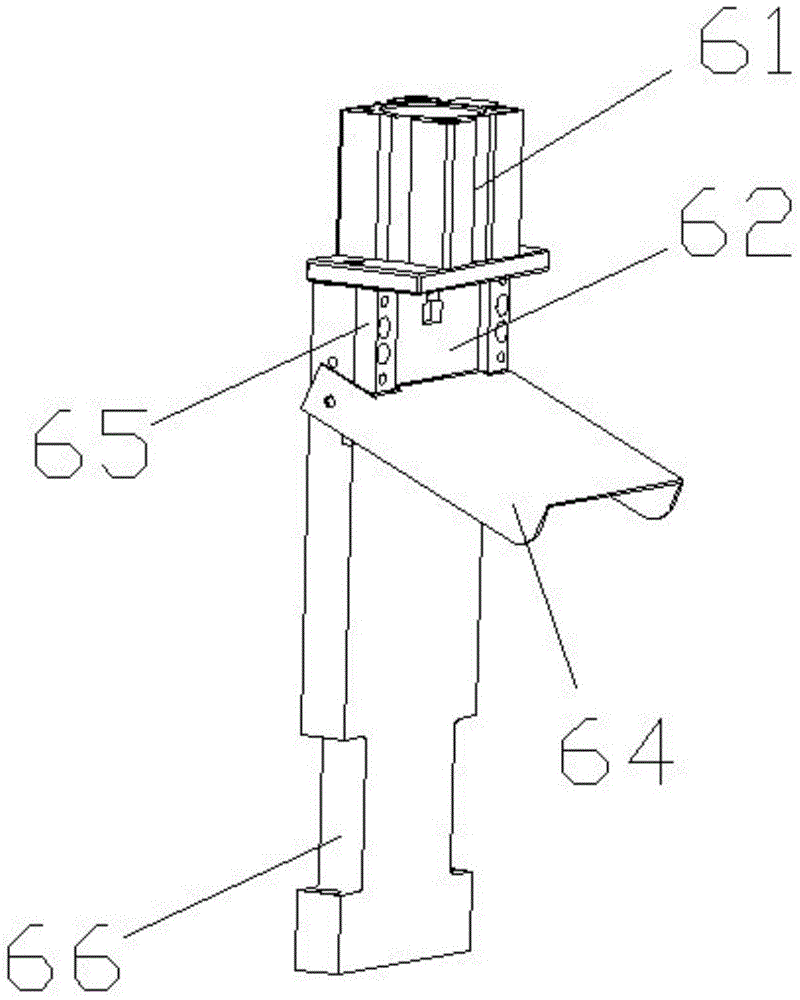

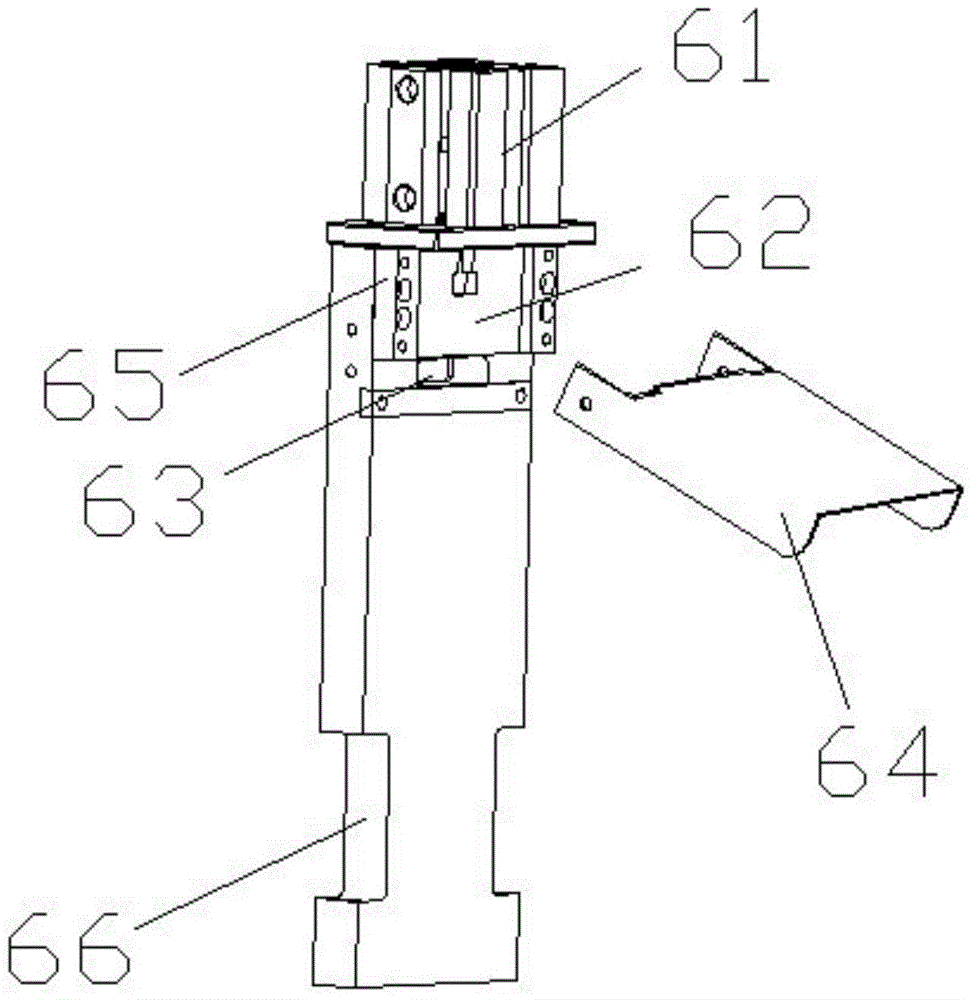

[0014] as attached figure 1 , 2 Shown is the cutting device for the volume control part automatic welding machine according to the present invention, which includes a cutting drive device 61, a cutting punch 62, a cutting edge 63 and a strip baffle 64; the height of the cutting edge 63 is the same as the guide The height of the material rack is even, and the strip material can enter from the cutting edge 63; the cutting punch 62 is arranged above the front part of the cutting edge 63, and can move up and down to cut off the waste belt; the cutting drive device 61 is arranged on the cutting edge. Above the head 62, the strip baffle plate 64 is arranged on the top of the cutting edge 63 to prevent the waste strip from upturning during cutting; the both sides of the cutting punch 62 are provided with punch guide rails 65, which give the cutting punch 62 The up and down movement is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com