Blasting experiment device for injection hose assembly of wheeled fire extinguisher

A technology for hose assemblies and experimental devices, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of poor health of operators, low test quality and efficiency, and low degree of automation, so as to protect physical health, The effect of reducing human operation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

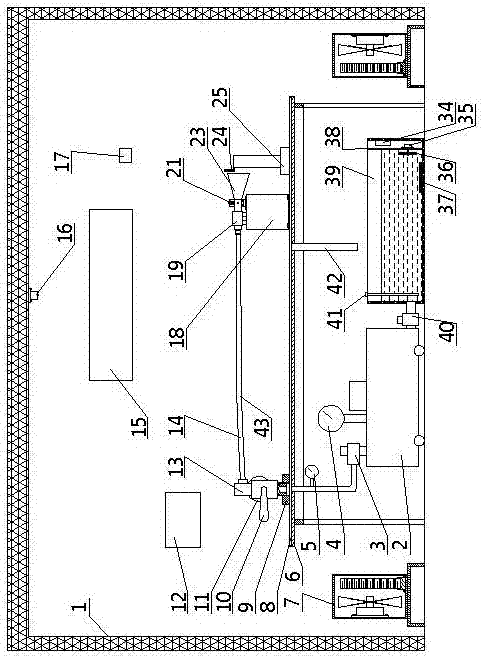

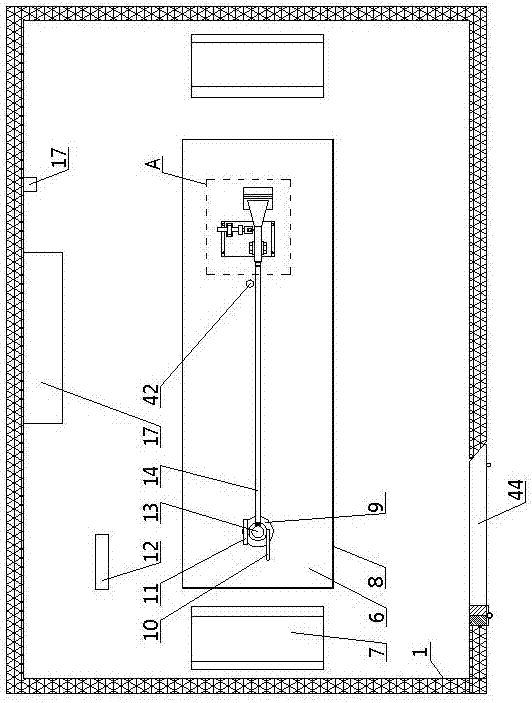

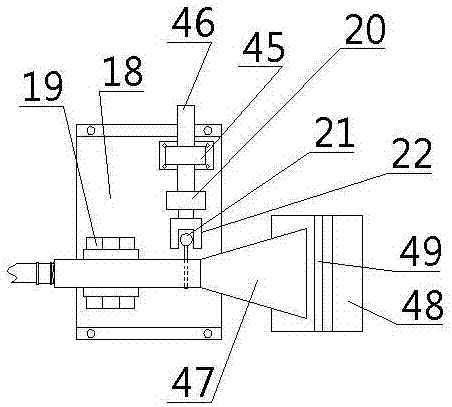

[0021] Accompanying drawing is a kind of specific embodiment of the present invention.

[0022] The blasting experiment device of the spray hose assembly of the cart-type fire extinguisher of the present invention comprises an explosion-proof chamber 1, a workbench 6, a water pressurization mechanism, a display PLC controller 12 and a heater 7, and is characterized in that: inside the explosion-proof chamber 1 A table-type workbench 6 is provided, and the workbench 6 is provided with a trolley-type fire extinguisher spray hose assembly sample 43 clamping and fixing structure, the fire extinguisher head 13 of the sample is connected with a water booster mechanism, and the nozzle end of the sample A water sensor 24 and an injection valve switch wrench opening and closing mechanism are provided; a heater 7 and an air conditioner 15 for adjusting the indoor temperature are also installed in the explosion-proof chamber 1, and an indoor temperature sensor 17 for detecting the indoor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com