Monomer recovery device in carbon fiber precursor production and method thereof

A technology for recycling carbon fiber precursors and monomers, which is applied in the field of monomer recovery devices in the production of carbon fiber precursors. It can solve the problems that the temperature control of the tower kettle cannot be automatically controlled, and achieve the effect of reducing personnel operations and avoiding misoperations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention is further described below in connection with the examples.

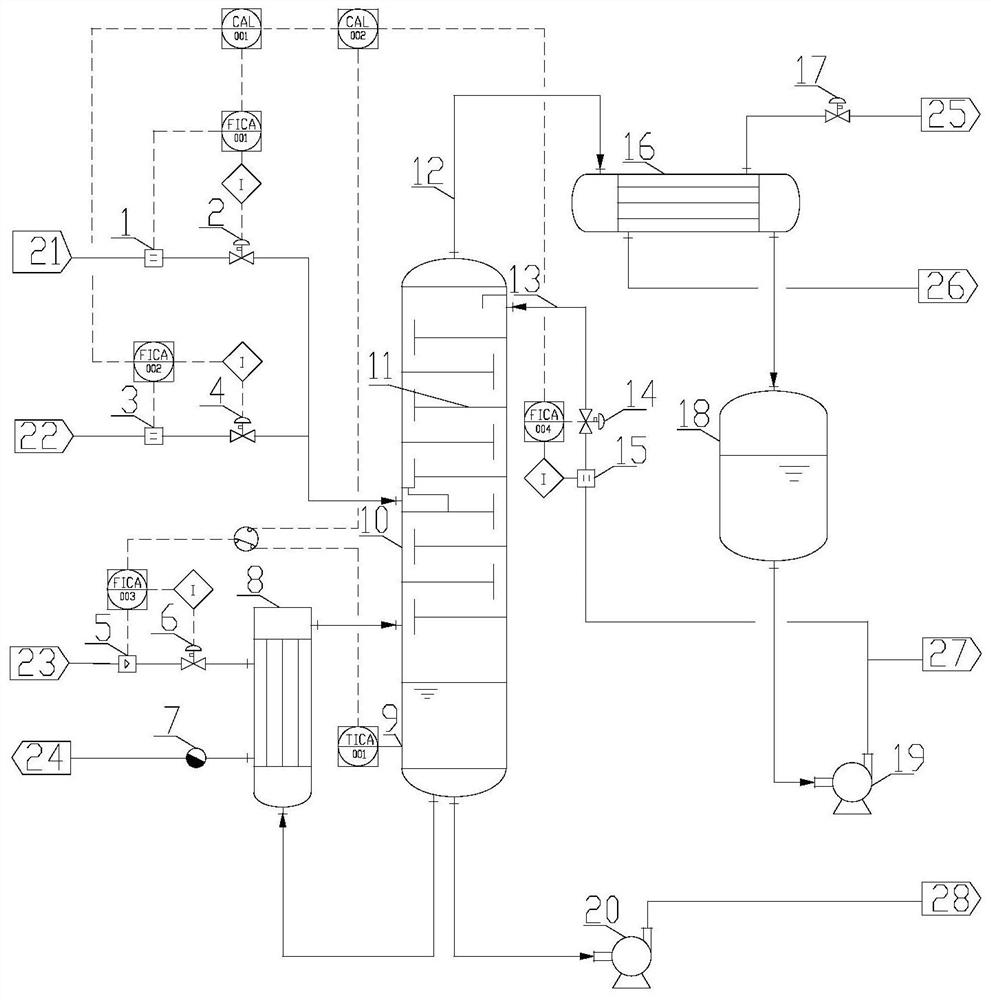

[0031] like figure 1 , The present invention provides a monomer recovery apparatus production of carbon fiber precursor, which is provided with a feed flow meter M1. 1, M1 feed control valve 2, M2 feed flow meter 3, M2 feed adjusting valve 4, the steam feed flow meter 5, steam feed control valve 6, the steam condensate trap 7, 8 reboiler, monomer recovery column 10, plates 11 monomer recovery column, reflux control valve 14; 15, 15 reflux flow meter ; 16, overhead condenser 16; 17, chilled water control valve 17; 18, reflux drum 18; 19, return pump 19; 20, recovery tower bottom pump 20.

[0032] The index process control procedure, provided the feed flow meter M1 and M2 feed 1 flow meter 3, and constitute FICA001 FICA002 circuit controlled by the feed control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com