High-precision heavy-load assembly robot

A large-load, robotic technology, applied in the field of robotics, can solve problems such as reduced operational reliability, large workshop space occupation, and reduced structural rigidity, achieving the effects of simple control and implementation, compact installation, and reduced control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

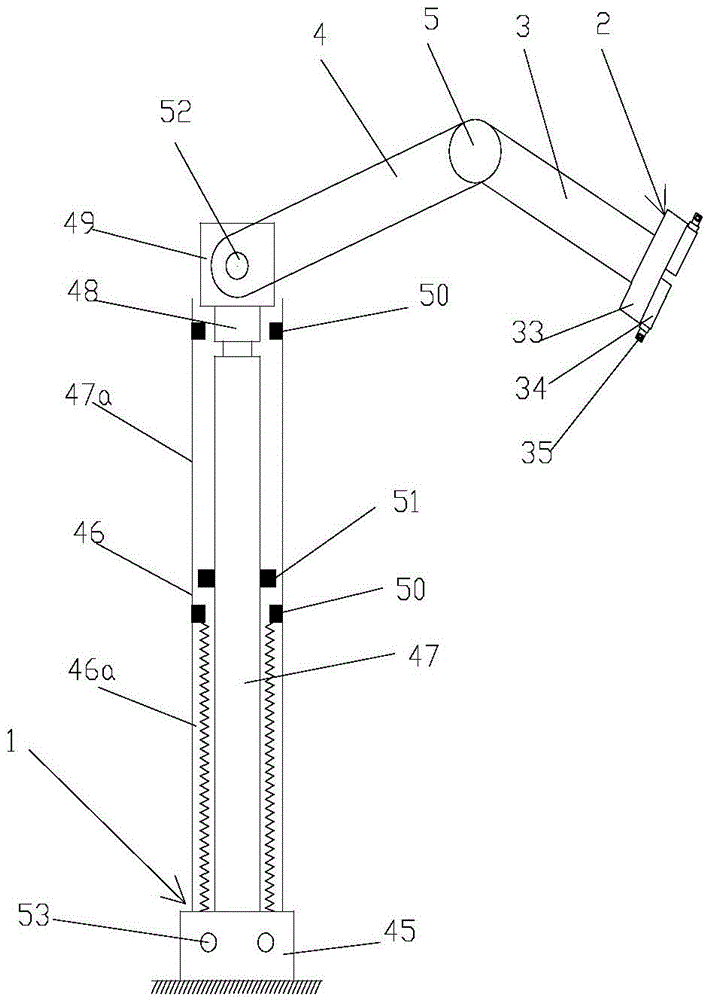

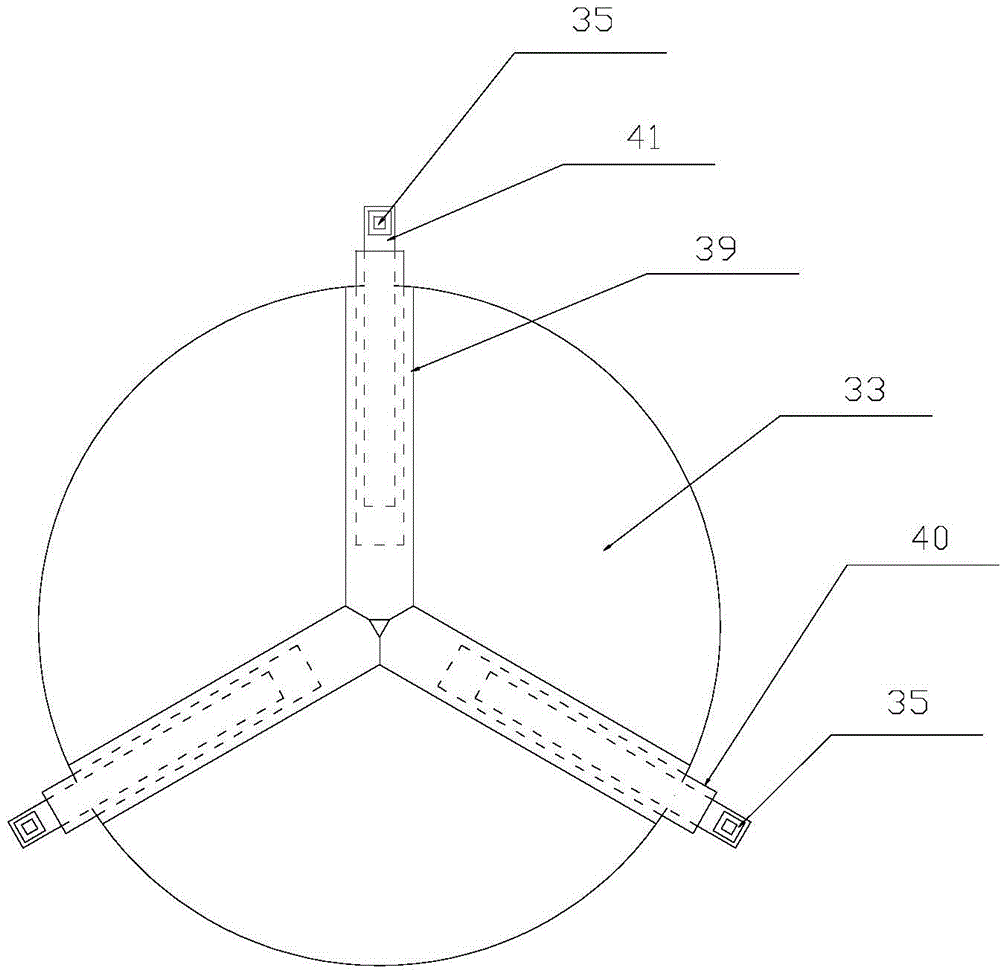

[0032] As shown in the figure: the high-precision and large-load assembly robot of this embodiment includes a base assembly 1, an arm assembly, an end effector 2 and a control system. The arm assembly includes a forearm 3, a rear arm 4 and a forearm 3 respectively. A compound joint 5 that is articulated with the rear arm 4 and can realize the lateral swing, pitch and revolution motion of the forearm 3. The end effector 2 is connected to the forearm 3, and the rear arm 4 is arranged in cooperation with the base assembly 1 in a manner that can be turned up and down. The rear arm 4 can also rotate in a vertical plane;

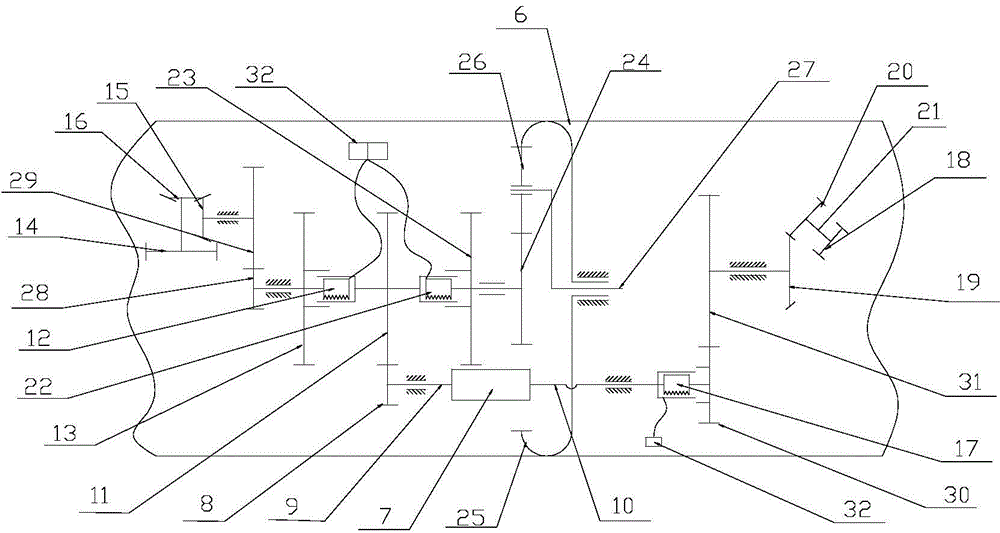

[0033] The compound joint 5 includes a joint housing 6 and a motion drive assembly. The motion drive assembly includes a main drive device, a side swing motion transmission assembly, a pitch motion transmission assembly and an epicyclic motion transmission assembly. The main drive device includes a main drive motor 7 and a main drive The gear transmission pair, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com