Bonding method of belt on belt conveyor

A belt conveyor and bonding method technology, which is applied in the field of metallurgical rolling, can solve the problems of high cost of replacing new products, dismantling the rack, etc., and achieve the effects of reducing maintenance and replacement time, increasing production efficiency, and improving production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

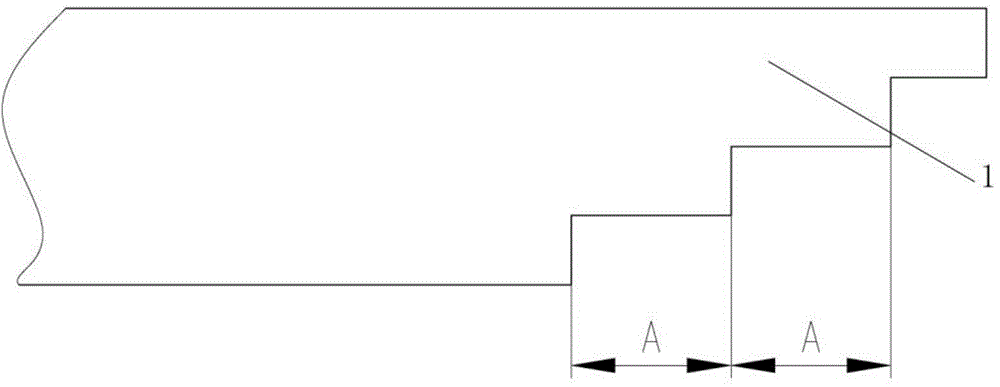

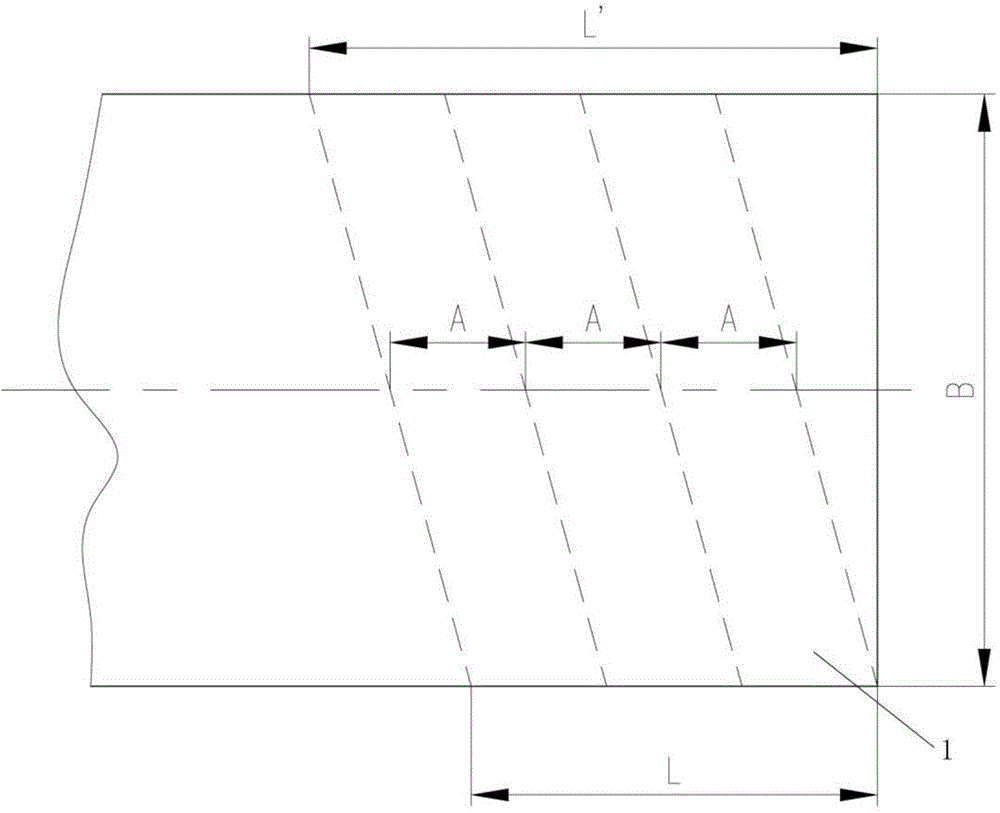

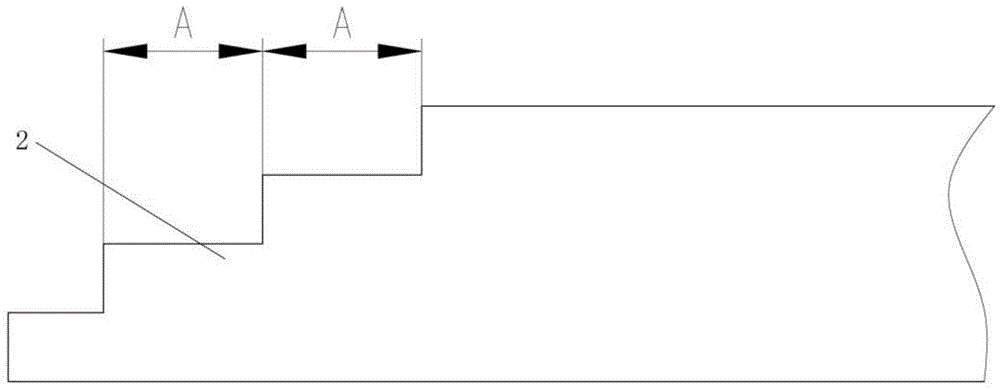

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , the preparatory step of the method of the present invention is, in the docking area of the left end joint 1 and the right end joint 2 that need to be docked, a plurality of step steps obliquely intersecting with the longitudinal centerline of the belt are correspondingly provided, wherein the belt width is B, and the belt step The width is A, the length of the inner end of the step bevel (joint length) is L, and the length of the outer end of the step bevel is L'.

[0021] The present invention adopts the oblique section stepped joint form to bond the belt, and adopts a plurality of step steps obliquely intersecting with the longitudinal center line of the belt. The relationship between the number of cut layers X of the joint steps and the number of layers Y of the belt canvas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com