Vacuum bag reusing structure

A vacuum bag and putty technology, which is applied in the field of composite material manufacturing, can solve the problems of deformation, insufficient strength of putty strips and vacuum films, and high production cost, and achieve the effects of reducing pollution, saving production cost and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

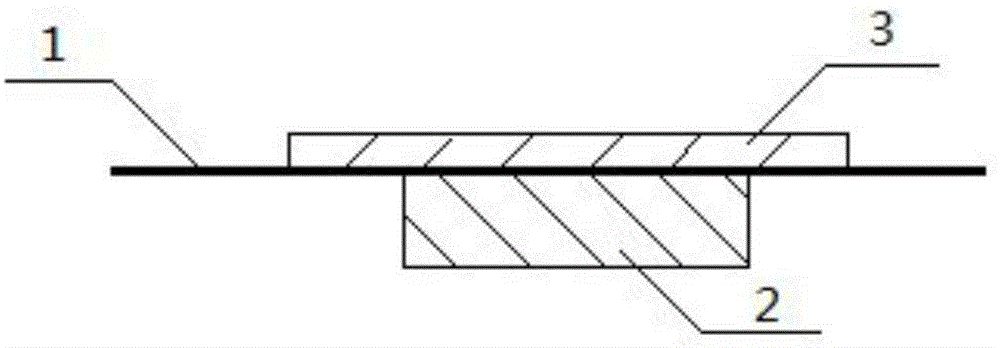

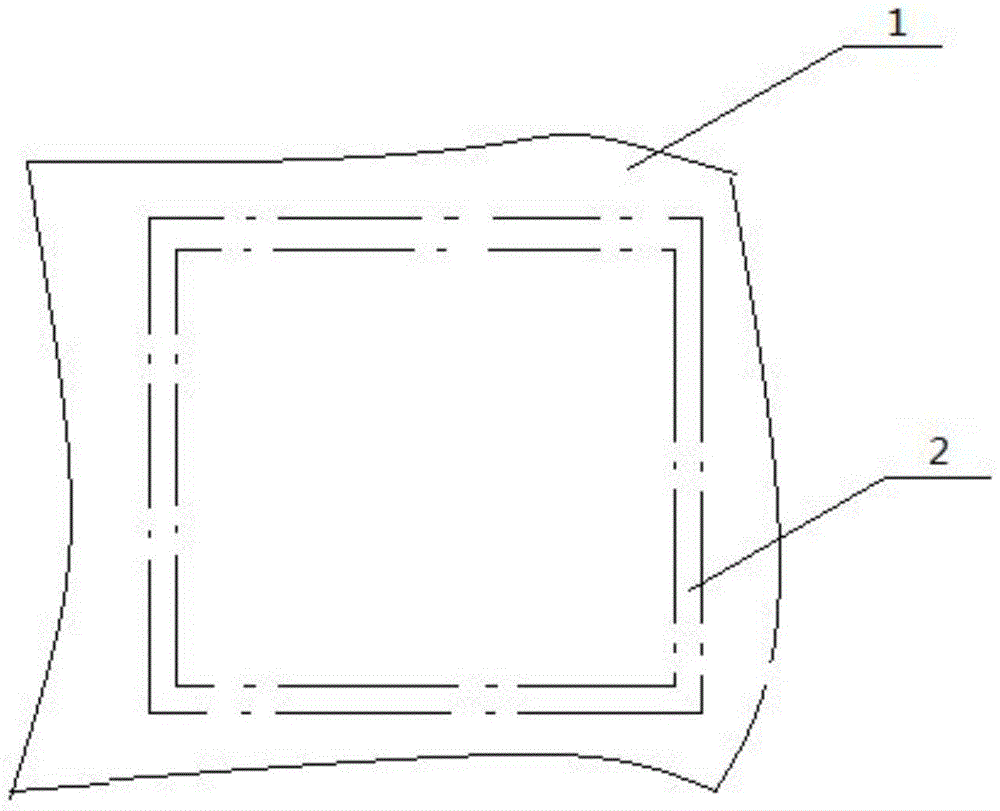

[0012] The present invention is described below in conjunction with accompanying drawing:

[0013] A structure capable of reusing a vacuum bag, comprising a putty strip 2, a mold, and a vacuum bag 1, the putty strip 2 is bonded to the mold, and then the vacuum bag 1 is crimped on the putty strip 2, the mold, the putty strip 2 1. A sealed space is formed between the vacuum bags 1, which is characterized in that: it also includes a self-adhesive reinforcement strip 3, and the self-adhesive reinforcement strip 3 is pasted outside the vacuum bag 1, and the bottom of the self-adhesive reinforcement strip 3 is in the direction of the putty strip 2 match.

[0014] When in use, even if the vacuum bag 1 is in a complex environment, that is, when processing parts with excessive curvature or complex shapes, the corresponding curvature of the mold is also large, and the adhesion between the vacuum bag 1 and the putty is not good when the shape is complex. , and even affect the degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com