Track detection method

A track detection and track technology, which is used in railway vehicle shape measuring instruments, railway car body parts, railway auxiliary equipment, etc. Accuracy and detection efficiency, penetration ability and strong anti-interference ability, and the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

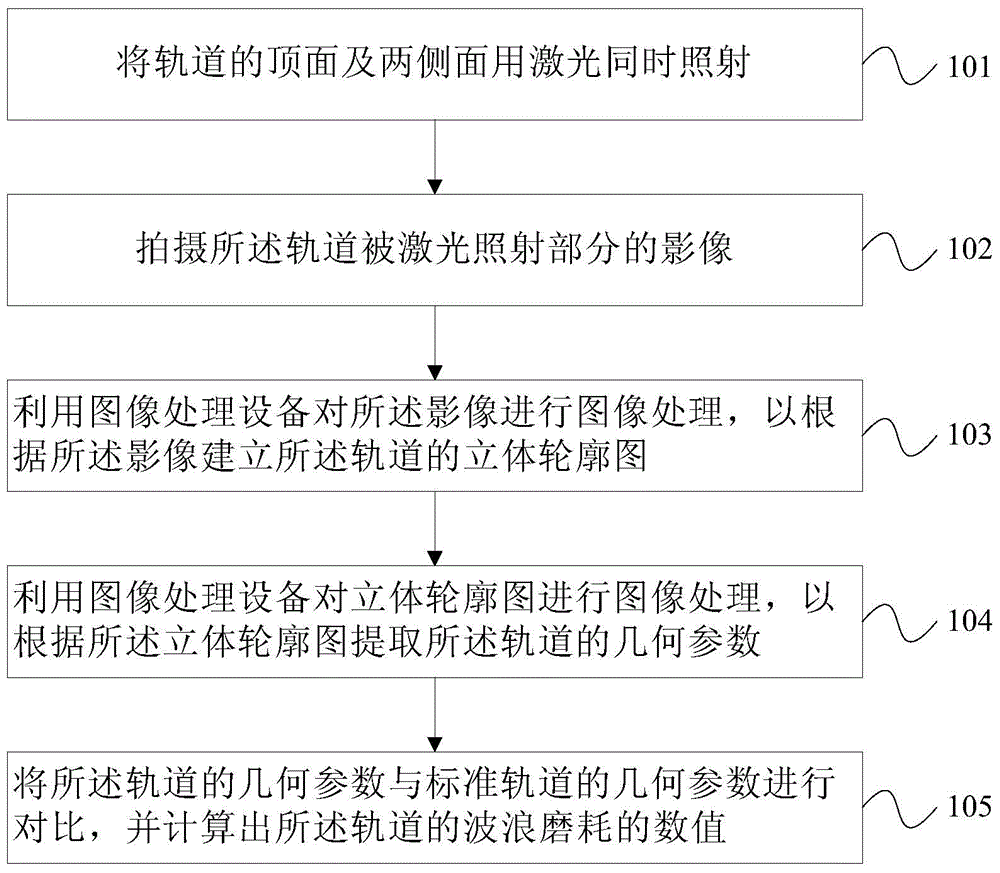

[0014] Please refer to figure 1 , the specific steps of a track detection method provided in the embodiment of the present invention are as follows:

[0015] Step 101, simultaneously irradiating the top surface and both sides of the track with laser light.

[0016] Since the top surface and both sides of the track will be worn by waves during use, in order to establish a three-dimensional contour map of the track and obtain accurate values of wave wear in the subsequent steps, it is necessary to first irradiate the top and two sides of the track with laser . Due to the strong penetrating ability and anti-interference ability of laser, the use of laser to illuminate the top surface and both sides of the track can improve the clarity of subsequent image shooting, so that subsequent measurement data will not be affected by dust or other light, ensuring measurement Data Accuracy. .

[0017] Preferably, step 101 includes step 106 and step 107 .

[0018] Step 106, simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com