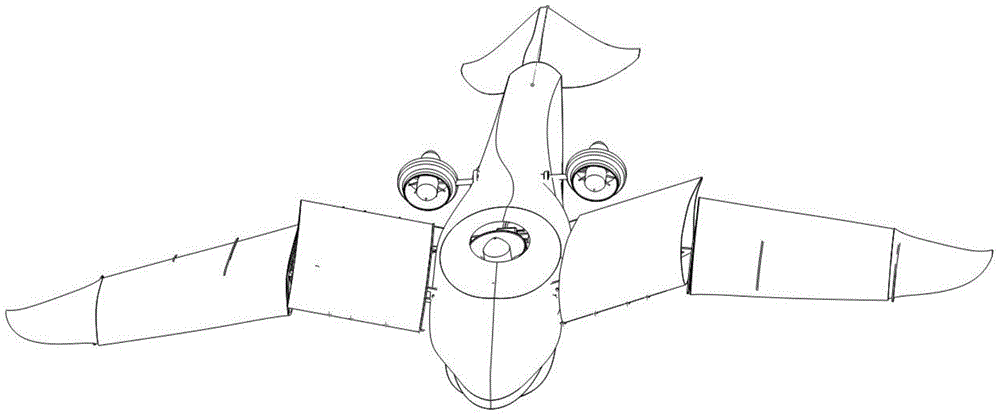

Small flapping wing type ducted aircraft

An aircraft and ducting technology, applied in the field of new aircraft, can solve the problems of low speed, short endurance time, and small thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

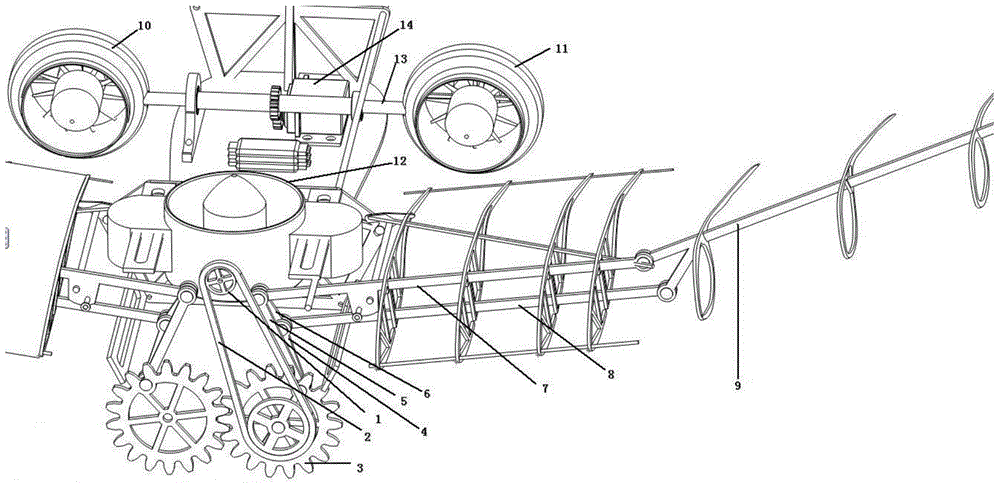

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

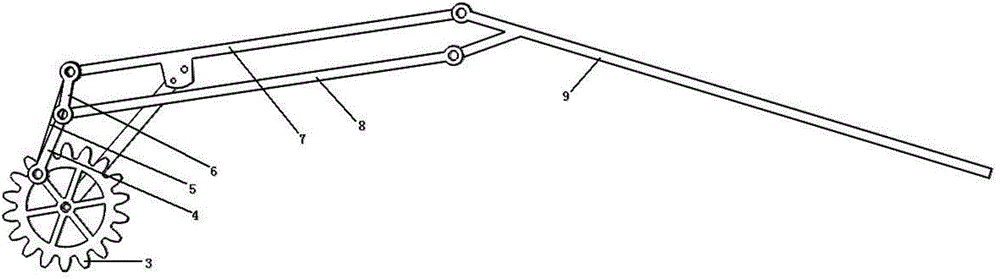

[0012] The main drive motor of the flapping wing mechanism drives the synchronous pulley 1 to rotate, and the synchronous pulley 1 drives the double gear 3 (in the same body as the large synchronous pulley) to rotate through the synchronous belt 2, and the double gear 3 drives the main connecting rod 5 and the auxiliary connecting rod 4 , auxiliary connecting rod 6 motions, main connecting rod 5, auxiliary connecting rod 4, auxiliary connecting rod 6 three constitute " triangular structure ", and the three are relatively motionless. The main link 5, the secondary link 4, and the secondary link 6 drive the primary rocker (primary main bone 7, primary secondary bone 8) to move, and the primary rocker drives the secondary rocker (secondary main bone 9) to move . The primary rocker and the secondary rocker work together to complete the bionic flapping motion.

[0013] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com