An automatic feeding and discharging device and feeding and discharging method

An automatic technology for feeding and unloading materials, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of cumbersome operation of feeding and unloading structures, drug pollution, complex structures, etc., to achieve small footprint, reduce friction, and easy operation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

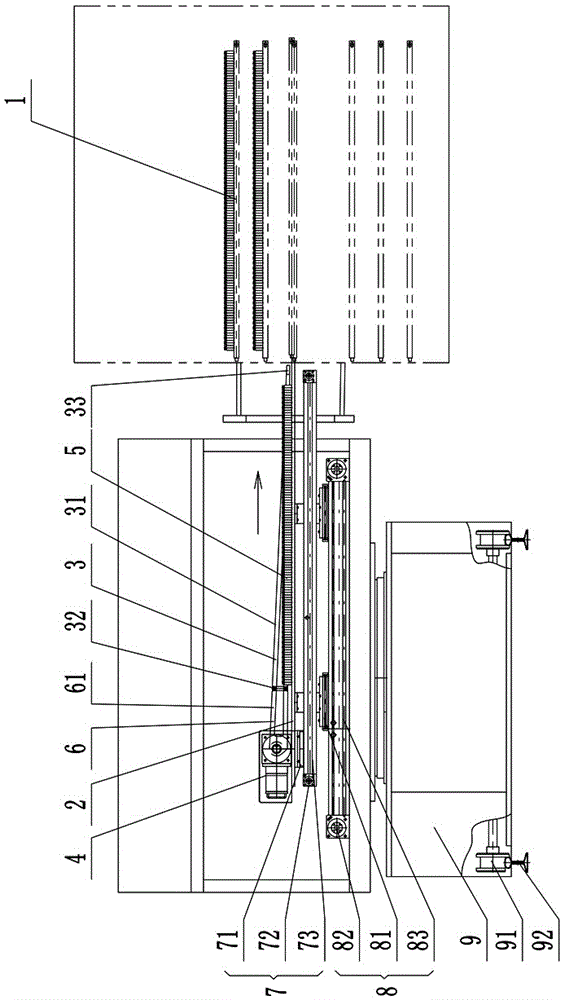

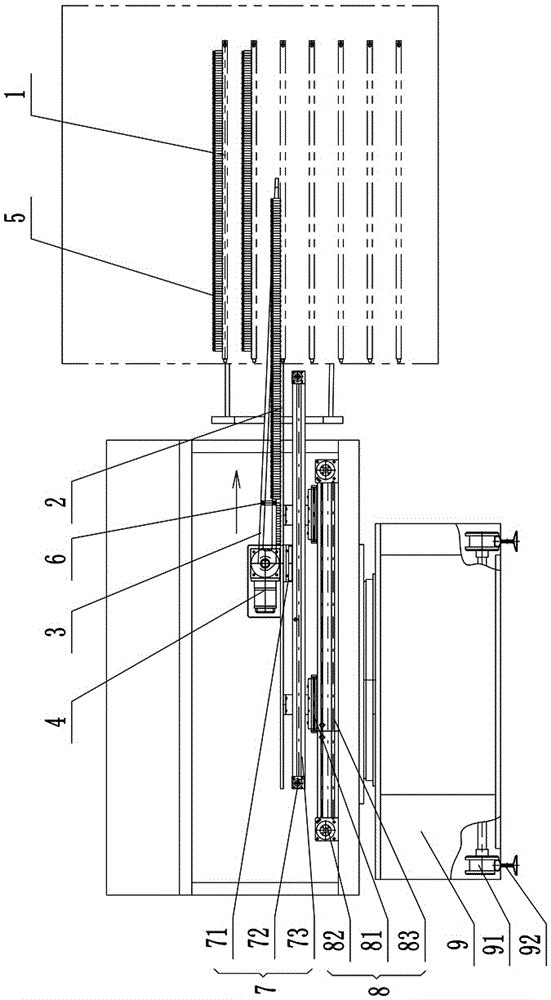

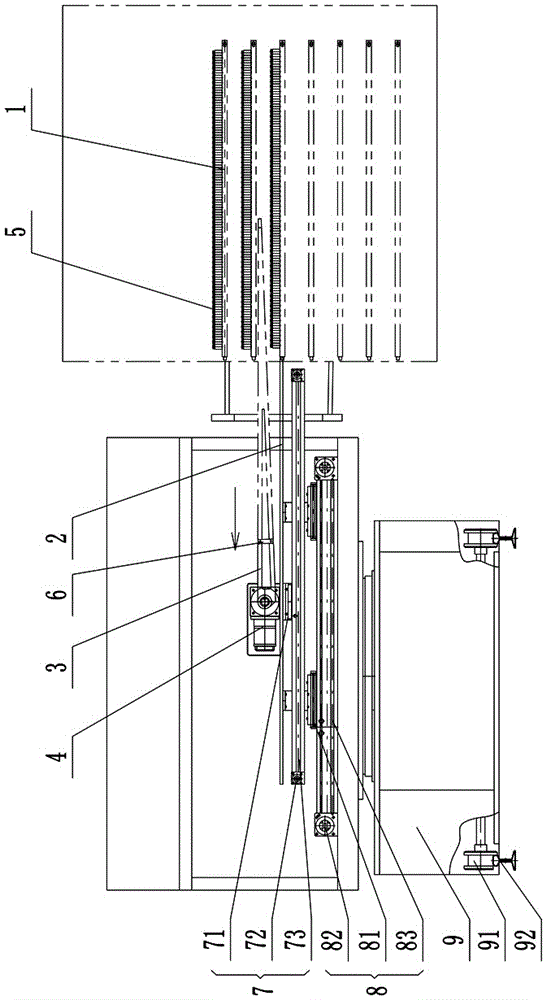

[0031] Such as Figure 1 to Figure 6 As shown, the automatic feeding and unloading device of this embodiment includes a bottle collecting platform 2 and a bottle shifting assembly. 2 to do linear reciprocating motion, the bottle moving assembly includes a bottle catch frame 3, the bottle catch frame 3 is located on the bottle collection platform 2, the bottle catch frame 3 is composed of side frame plates 31 located on both sides of the bottle collection platform 2 and two sides Rear frame plate 32 between side frame plates 31, front frame plate 33 form, rear frame plate 32 is used for pushing bottle and bottle protection, and front frame plate 33 is used for pulling bottle and bottle protection. The rear frame plate 32 of the bottle catcher frame 3 is connected with a rotary drive member 4, and the rotary drive member 4 drives the bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com