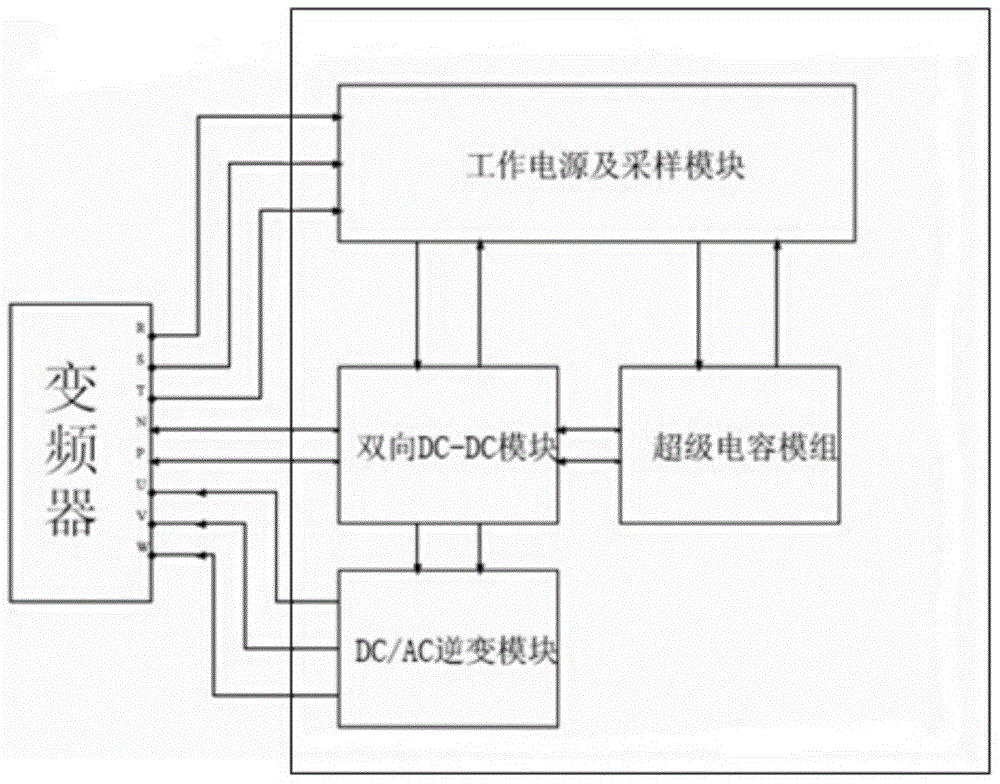

Elevator variable-frequency traction equipment energy saving system using bidirectional DC (direct current)-DC module

An energy-saving system and elevator technology, applied to elevators in buildings, electric energy storage systems, electrical components, etc., can solve problems such as unusable, power grid impact, thermal pollution, etc., and achieve safe, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Basic conditions:

[0021] 1 Elevator bus voltage (V1)

[0022] 2 Reference mains voltage (V2)

[0023] 3 supercapacitor module voltage (V3 working voltage range 90V-150V)

[0024] 4 Mains V4

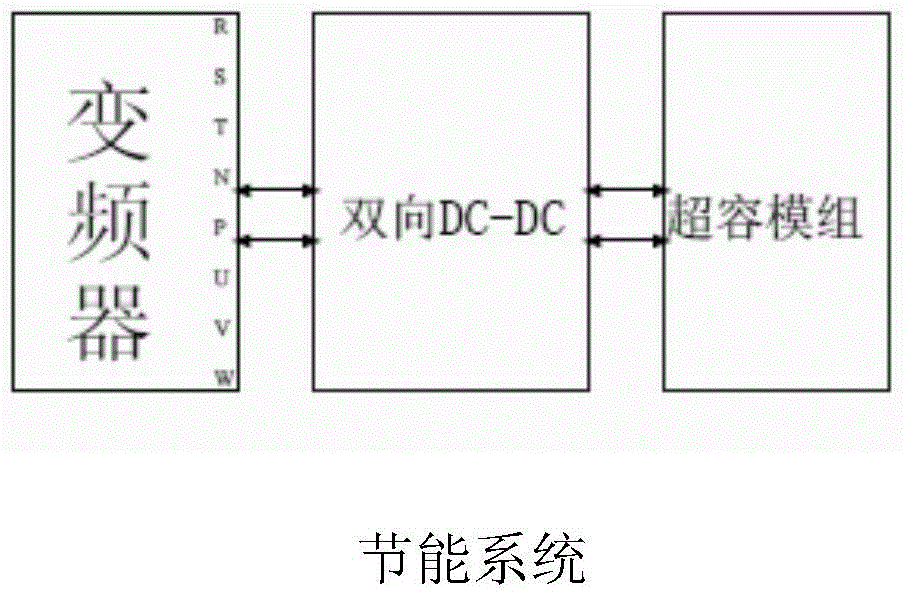

[0025] When V1>V2, and V3<150; the elevator is in a state of potential energy, and V1 charges V3 through DC-DC. When V1<V2, and 110V<V3<150V; the elevator is in a non-potential energy state, and V3 sends electric energy back to V1 through DC-DC. At this time, when the power required by the elevator is greater than the power increased by the energy-saving system, the insufficient part is provided by the mains.

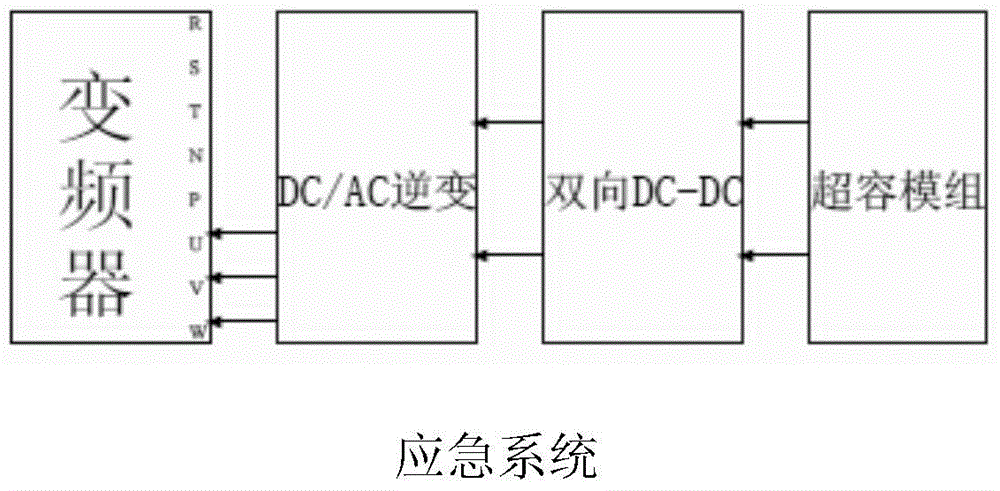

[0026] When V4=0; at this time, the ultra-capacity module provides three-phase 380V mains power to the elevator through DC-DC, DC / AC, and supplies the elevator for emergency use.

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com