Template hoisting device

A lifting device and formwork technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of manpower consumption, unbalanced force, construction accidents, etc., and achieve the effect of saving manpower, firm connection and good balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

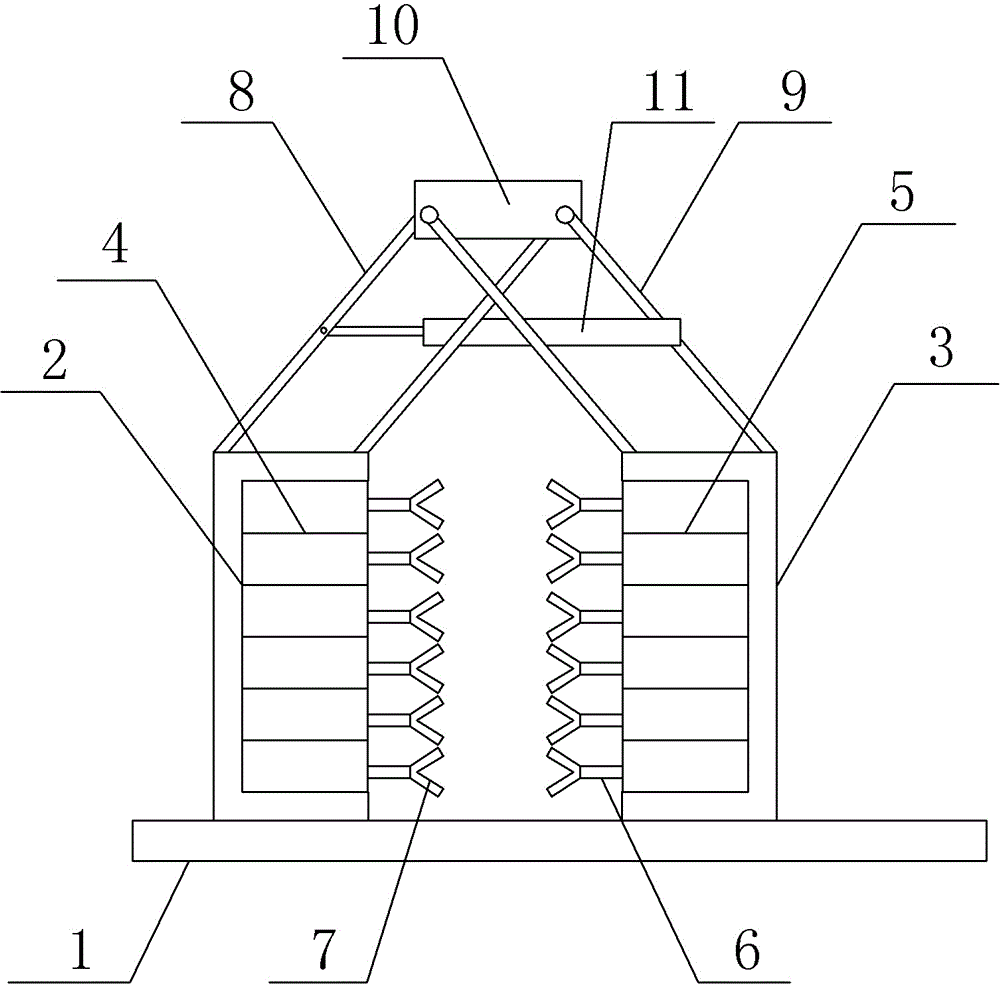

[0011] The reference signs in the drawings of the description include: base plate 1, left frame 2, right frame 3, left cylinder group 4, right cylinder group 5, piston rod 6, pneumatic gripper 7, left four-link 8, right four-link 9, hanging block 10, control cylinder 11.

[0012] The embodiment is basically shown in the accompanying drawings: the template lifting device includes a bottom plate, and a chute is installed on the surface of the bottom plate. The chute is matched with a left frame and a right frame through rollers, and the left frame and the right frame are mirror images.

[0013] There are left four-links and right four-links respectively installed above the left frame and the right frame, and the left four-links and right four-links are parallel four-bars. The lower end is hinged, the upper end of the right frame is hinged with the lower end of the right fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com