Active carbon filter

An activated carbon filter and filter layer technology, which is applied in the field of water filtration and purification devices, can solve the problems of difficult replacement of activated carbon, affect production efficiency, and reduce the adsorption effect of activated carbon, and achieve convenient and quick replacement of activated carbon, saving time and manpower , filter full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

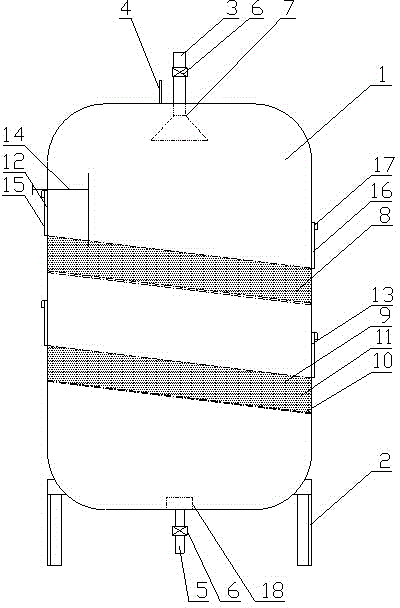

[0009] Such as figure 1 As shown, the preferred embodiment of the invention is: an activated carbon filter, including a cylinder 1 and a bracket 2, the upper end of the cylinder 1 is provided with a water inlet 3, and one side of the water inlet 3 is provided with an air inlet 4 , the lower end is provided with a water outlet 5, the cylinder 4 is fixed on the support 2, a flow control valve 6 is arranged at the water inlet 3 and the water outlet 4, and a nozzle is arranged at the lower end of the water inlet 3 7. The cylinder body 1 is provided with a first filter layer 8 and a second filter layer 9 with the same structure from top to bottom, both of which include a baffle 10 and an activated carbon layer 11. The first filter layer 8 and the second filter layer The layers 9 are all arranged obliquely in the cylinder 1, the inclination angle is 10-15 degrees, and the first filter layer 8 and the second filter layer 9 are arranged in parallel; in the first filter layer 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com