A kind of alkali-soluble acrylate polymer composition and preparation method thereof

A technology of acrylate and linear polymers, which is applied in the field of polymer synthesis and can solve problems such as high turbidity, limited thickening ability, and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

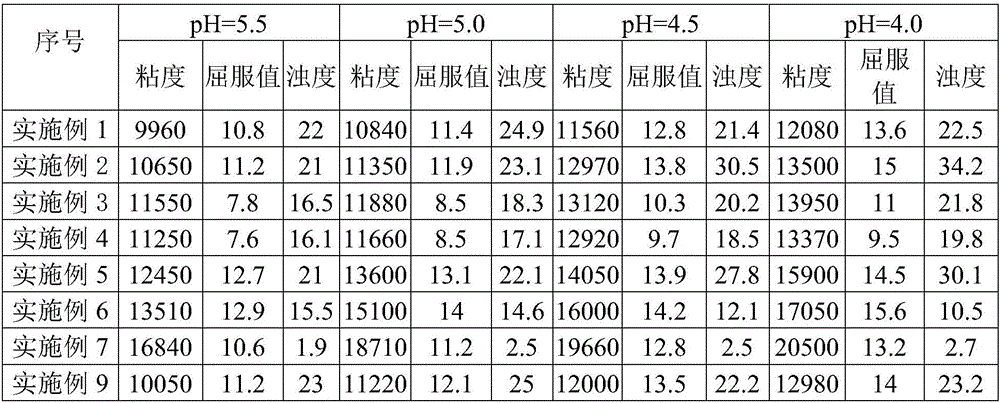

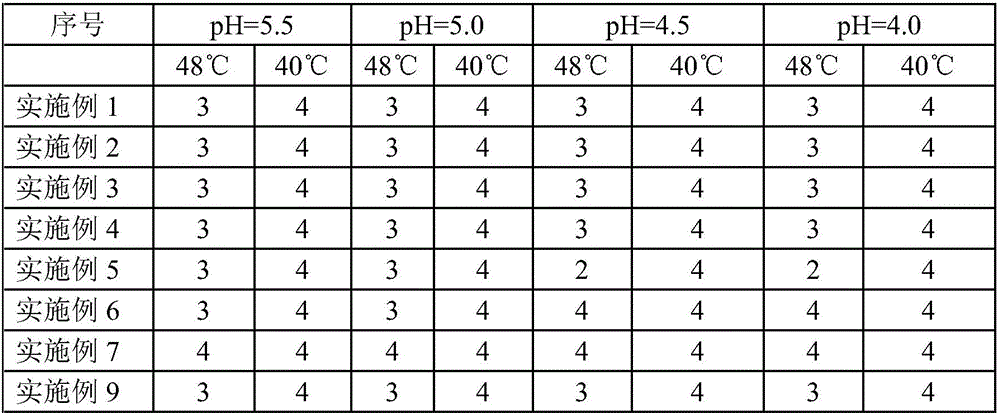

Examples

specific Embodiment 1

[0065] Add 166 g of acrylic acid and 324 g of methyl methacrylate into a 2 L four-neck flask equipped with a nitrogen device, a magnetic stirring device and a peristaltic pump to form a monomer phase.

[0066] Prepare 68 g of ammonium persulfate solution containing 1.12 g of ammonium persulfate, labeled as initiator.

[0067] Add 894g of deionized water, 13g of sodium lauryl sulfate, and 10g of methyl methacrylate into a 2L five-neck flask equipped with a nitrogen device, a condenser, a stirrer, a thermometer and a peristaltic pump, and add 10g of methyl methacrylate after stirring for 10 minutes. Based on acrylic acid, start stirring and ventilate nitrogen, raise the temperature of the system to 86°C, start to add the initiator (0.28mL / min) dropwise for 20min, and form a water phase.

[0068] Continue dripping the initiator at a speed of 0.28mL / min, and start to drop the monomer phase to the five-necked flask, the rate of addition is 2.29mL / min, stop dripping after the monome...

specific Embodiment 2

[0071] Add 166g of acrylic acid and 324g of ethyl methacrylate into a 2L four-necked flask equipped with a nitrogen device, a magnetic stirring device and a peristaltic pump to form a monomer phase.

[0072] Prepare 68 g of ammonium persulfate solution containing 1.12 g of ammonium persulfate, labeled as initiator.

[0073] Add 894g of deionized water, 13g of sodium lauryl sulfate, and 10g of methyl methacrylate into a 2L five-neck flask equipped with a nitrogen device, a condenser, a stirrer, a thermometer and a peristaltic pump, and add 10g of methyl methacrylate after stirring for 10 minutes. Based on acrylic acid, start stirring and blow nitrogen, raise the temperature of the system to 82°C, start to add the initiator (0.28mL / min) dropwise for 20min, and form the water phase.

[0074] Continue to drop the initiator at a rate of 0.28mL / min, and start to drop the monomer phase into the five-necked flask, the dropping rate is 2.29mL / min, the temperature is controlled at 82±1°...

specific Embodiment 3

[0077] It is substantially the same as Example 1, except that the crosslinking agent in the reaction process is 1 g of diallyl itaconate, and the initiator is 1.2 g of potassium persulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com