Grey disperse dye compound, disperse dye and preparation method and usage of disperse dye

A technology of disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of inconsistent dye lifting effect, high dye cost, large color difference between head and tail, etc., and achieves excellent fastness properties, Good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

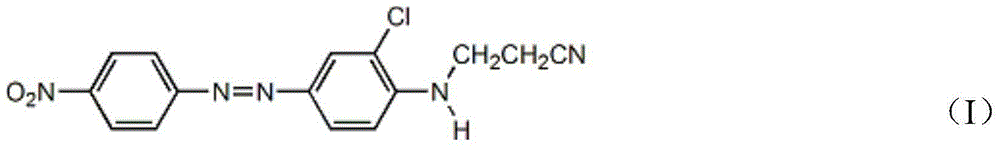

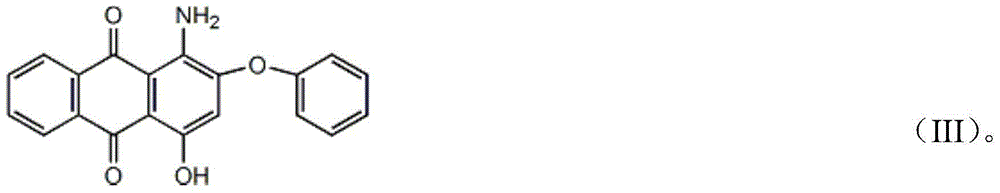

[0050] Add 20 grams of formula (I) component A, 54 grams of formula (II) component B, 26 grams of formula (III) component C, 200 grams of lignin 83A, 200 grams of diffusing agent MF, add 700 grams of water and stir well, Grind and disperse and dry to obtain gray disperse dyes.

Embodiment 2-10

[0062] According to the composition formula in Table 2, the gray disperse dye was made through stirring, grinding and drying. Wherein the moisture weight in Table 2 is the moisture weight of final gray disperse dye.

[0063] Table 2:

[0064]

[0065] The gray disperse dye of embodiment 2-10 is carried out performance test with the same method, compared with comparative example 1, the dyeing intensity of the gray disperse dye of embodiment 2-10 is high more than 3%, sublimation fastness reaches 4 grades, compatibility The performance reaches A-B level, and the cost is more than 3% lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com