Lace weaving device in shuttleless loom

A shuttleless loom and lace technology, applied in looms, auxiliary equipment for weaving, weaving, etc., can solve the problems of inability to weave lace fabrics and meet the diversification of the market, achieve rich diversification, promote development, increase The effect of life force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

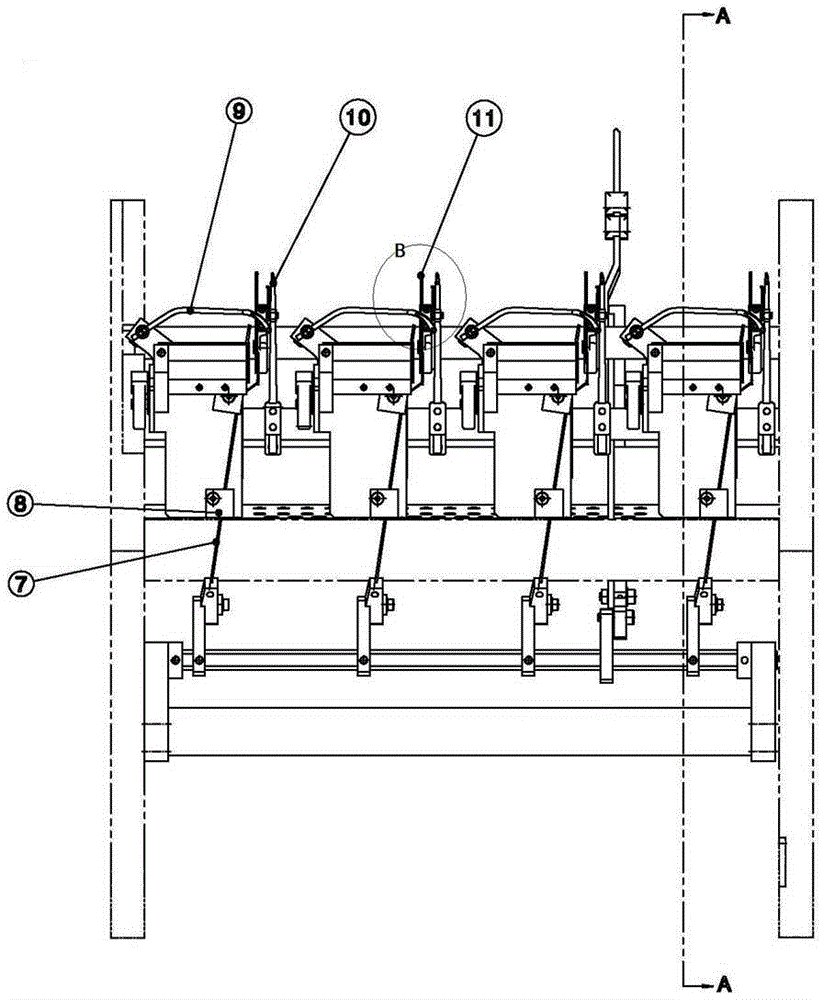

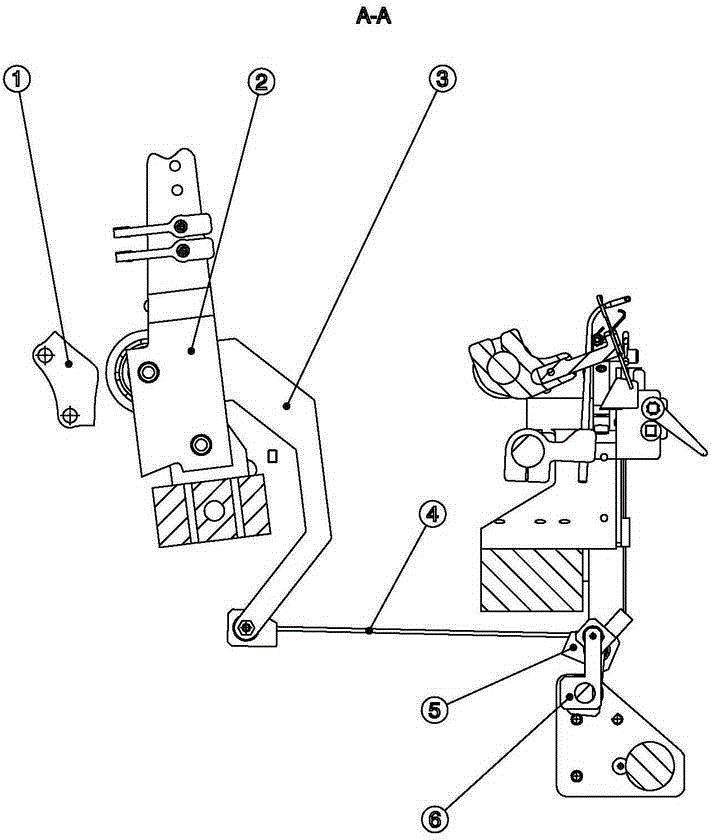

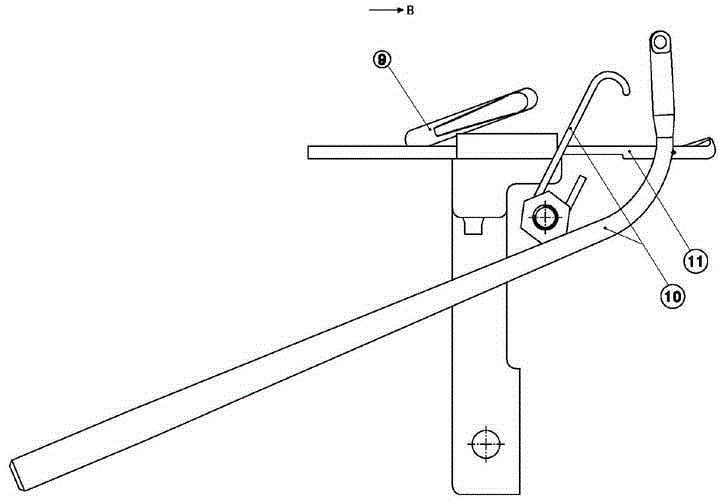

[0019] refer to Figure 1 to Figure 3 As shown, a lace weaving device in a shuttleless loom includes a flower chain piece 1, the outer curve of the flower chain piece 1 cooperates with the bearing outer ring on the blade set 2 to form a cam driving roller structure, and drives the blades The group 2 moves up and down, the blade group 2 drives and connects one end of the connecting rod 3, the up and down movement of the blade group 2 drives the connecting rod 3 to move up and down, and the other end of the connecting rod 3 is connected to the thin guide rod 4 through the rotating pin, and the thin guide rod 4 The other end of the connecting block 5 is fixed in the connecting block 5, and the up and down movement of the thin guide rod 4 drives the connecting block 5 to swing slightly, and the connecting block 5 transmits torque to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com