Urban rail traffic engineering electromechanical equipment embedded part installation method

A technology for urban rail transit and electromechanical equipment, applied in building components, building insulation materials, buildings, etc., can solve problems such as increasing operation and maintenance costs, health impacts of construction workers, and reducing engineering life, saving drilling and testing costs, The effect of reducing operation and maintenance costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

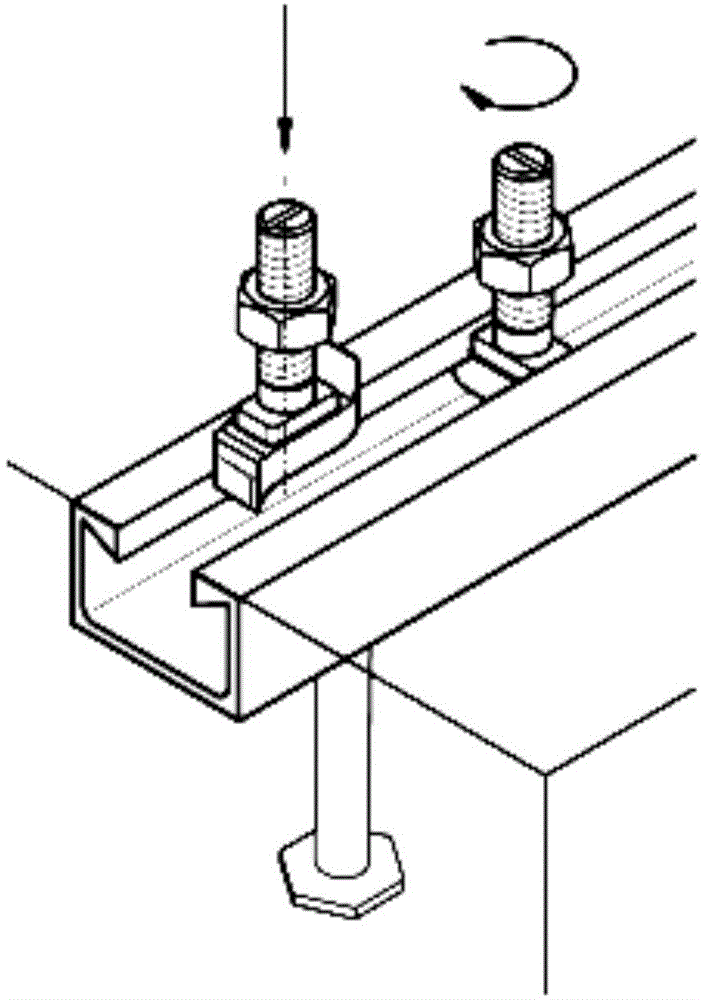

[0014] The present invention is achieved in this way. A method for installing pre-embedded parts of electromechanical equipment in urban rail transit projects pre-embeds the steel chute in concrete, and then buckles the big head of the T-shaped bolt into the C-shaped groove of the steel chute. The components are then fixed with T-shaped bolts, and the channel steel is filled with foam filler or strip filler material; it can prevent concrete from entering the channel steel, and the steel chute is also suitable for all fixtures that will undergo dynamic loads, such as lifting rails or mechanical fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com