Hydrostatic axial piston engine

一种轴向活塞机、活塞机的技术,应用在往复式活塞发动机、机械设备、发动机元件等方向,能够解决控制底部损坏等问题,达到避免损坏和毁坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

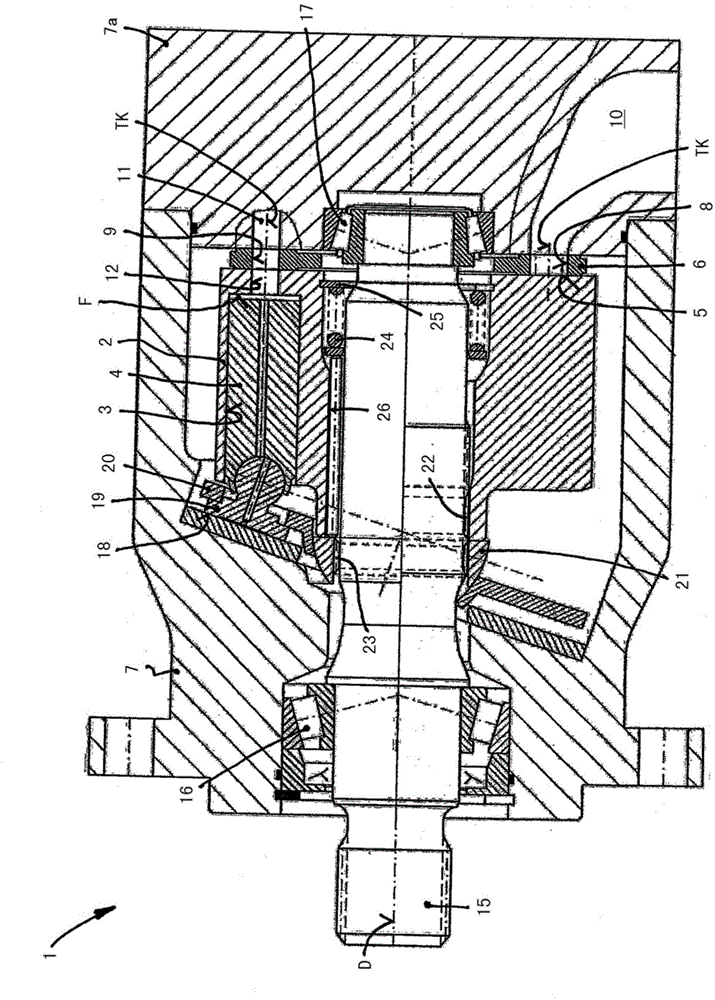

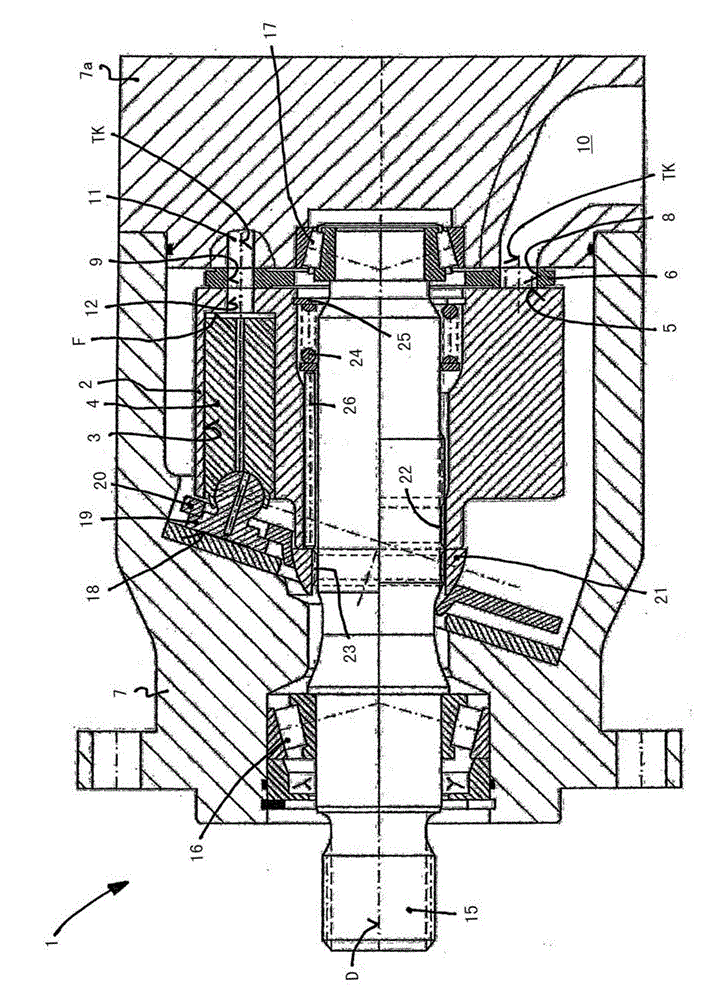

[0027] exist figure 1 A hydrostatic axial piston machine 1 of the swash plate embodiment according to the prior art is shown in longitudinal section, which operates with an open circuit and is optimized with regard to pump operation.

[0028] The axial piston machine 1 has a cylinder 2 arranged rotatably about an axis of rotation D, which is provided with a plurality of piston recesses 3 arranged coaxially with the axis of rotation D and arranged on a partial circle TK, The piston recesses are preferably formed by cylindrical bores and in each case a transmission piston 4 is mounted so as to be displaceable in the longitudinal direction.

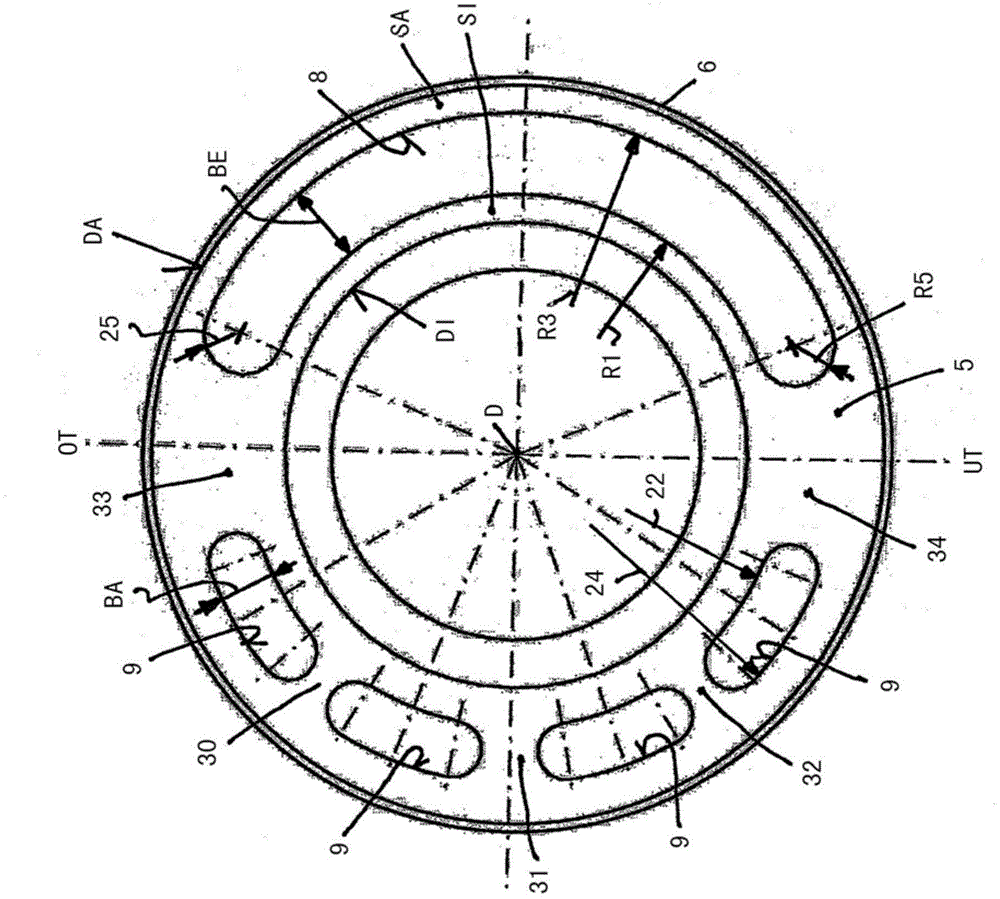

[0029] The cylinder 2 is supported in the axial direction with its end faces on a housing-fixed control surface 5 which is formed on a disk-shaped control base 6 which is fixed to the housing 7 in a non-rotatable manner. Or on the corresponding housing cover 7a of the housing 7. The control base 6 is equipped with kidney-shaped control slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com