Hydraulic power control system for hydraulic plug type lifting system

A control system and hydraulic power technology, applied in fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as slow lifting leg speed, achieve the effects of accelerating telescopic speed, ensuring stability, and increasing lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

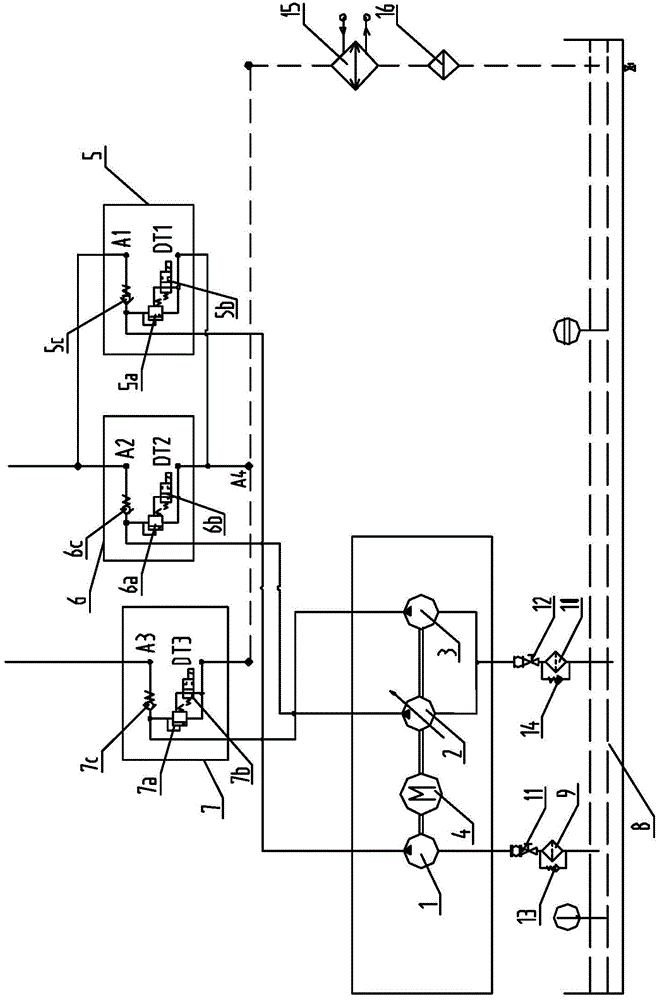

[0029] An embodiment of the present invention provides a hydraulic power control system of a hydraulic bolt-type lifting system, such as figure 1 As shown, the hydraulic power control system includes a hydraulic drive assembly, a first unloading circuit 5, a second unloading circuit 6, a third unloading circuit 7 and a main control valve 17. The hydraulic drive assembly includes a first hydraulic pump 1, The second hydraulic pump 2, the third hydraulic pump 3 and the driving device 4 for powering the first hydraulic pump 1, the second hydraulic pump 2 and the third hydraulic pump 3, the first unloading circuit 5 includes a first pilot relief valve 5a and the first two-position two-way solenoid valve 5b, the second unloading circuit 6 includes the second pilot relief valve 6a and the second two-position two-way solenoid valve 6b, the third unloading circuit 7 includes the third pilot relief valve 7a and the third two-position two-way solenoid valve 7b.

[0030] The oil outlet ...

Embodiment 2

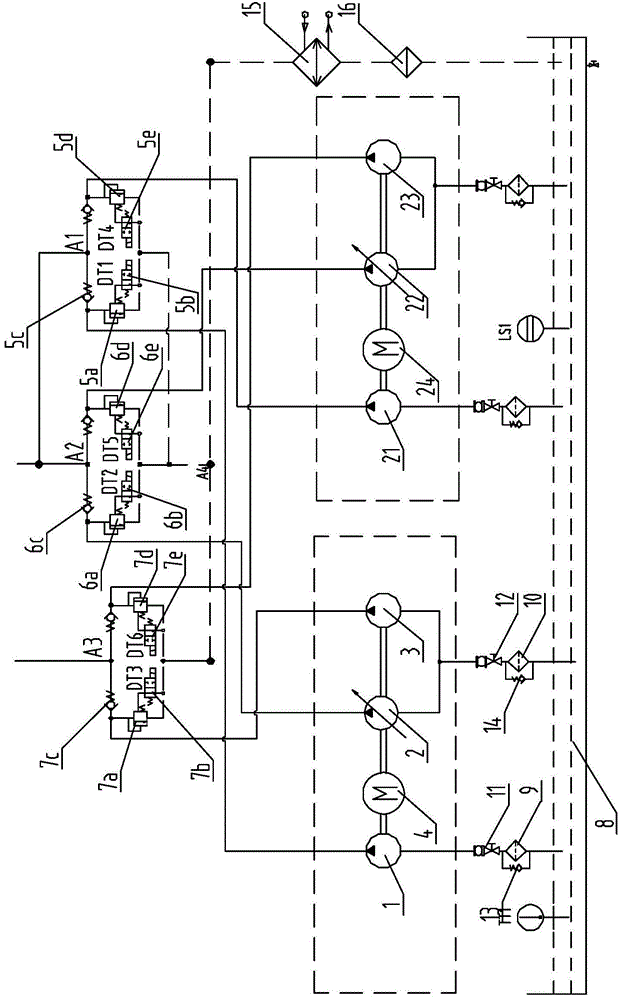

[0052] An embodiment of the present invention provides a hydraulic power control system, such as image 3 As shown, the difference between the hydraulic power control system and the first embodiment is that the hydraulic power control system can also include a second hydraulic power control system including a second hydraulic drive assembly, a fourth unloading circuit, a fifth unloading circuit and a second hydraulic power control system. Six unloading circuits, the second hydraulic power control system includes the second hydraulic drive assembly, the fourth unloading circuit, the fifth unloading circuit and the sixth unloading circuit and the hydraulic drive assembly, the first unloading circuit 5, the second unloading circuit The unloading circuit 6 and the third unloading circuit 7 have the same structure, and the second hydraulic drive assembly includes a fourth hydraulic pump 21, a fifth hydraulic pump 22, a sixth hydraulic pump 23 and a second driving device 24, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com