Reduction gear with group drive of involute gear and cycloid gear

A technology of involute gear and cycloid gear, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of complicated installation, high machining precision and high cost of cycloid planetary reduction gear, To achieve the effect of reliable use, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

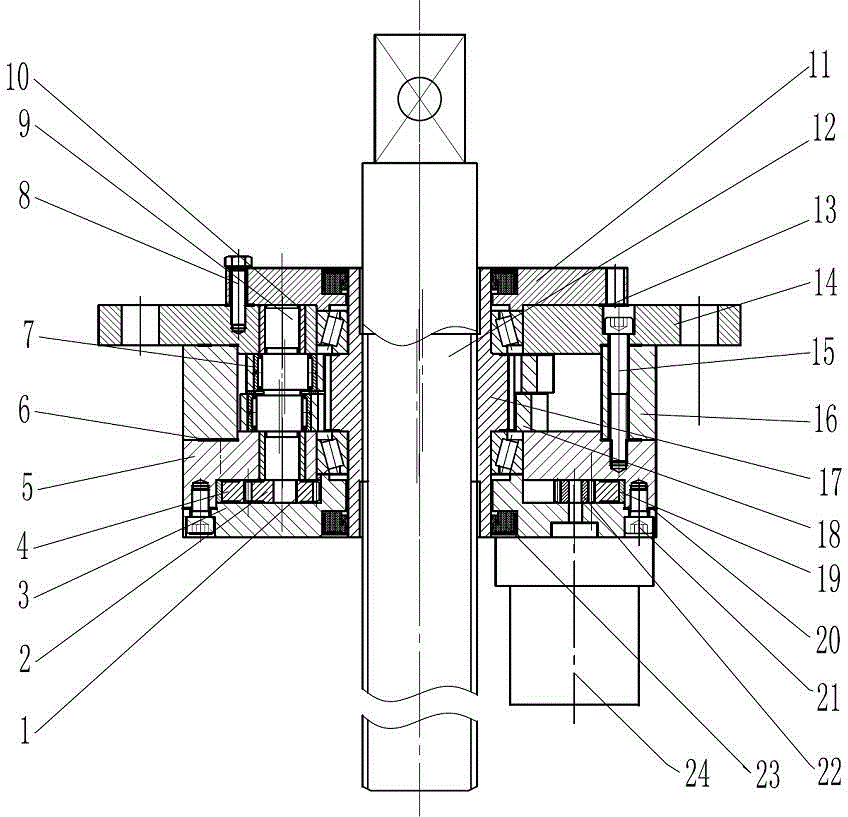

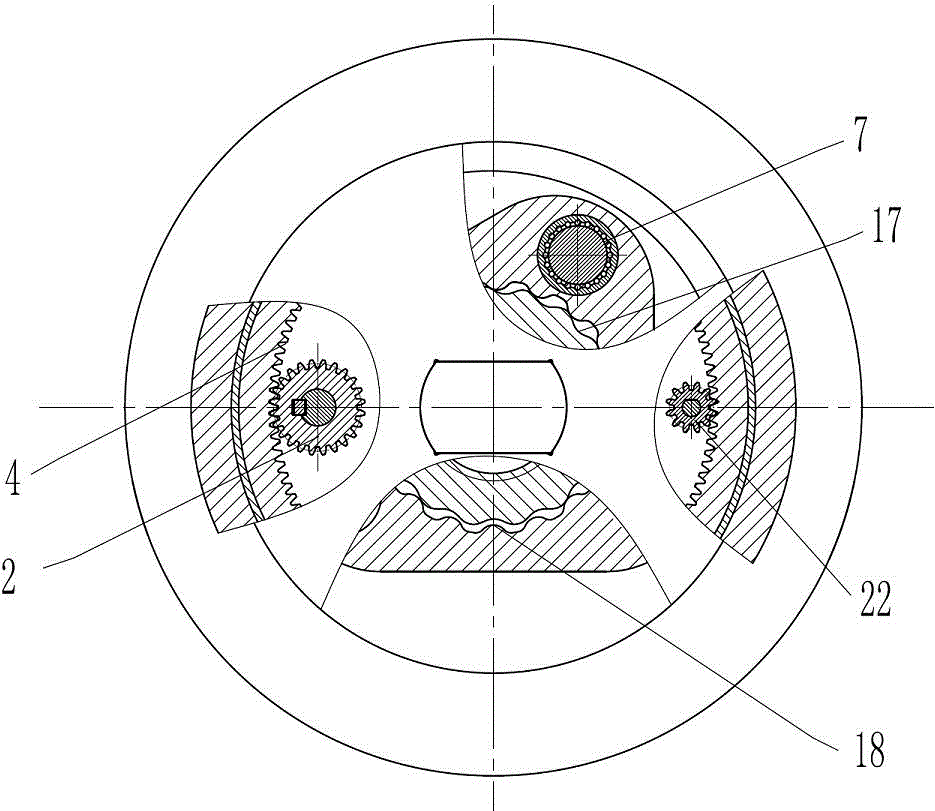

[0019] see figure 1 with figure 2 , figure 1 It is a general sectional view of the structure of the present invention; figure 2 It is a cross-sectional top view of the structure of the present invention; this embodiment is a reduction gear combined with an involute gear and a cycloid gear, which is used in a solar tracking device.

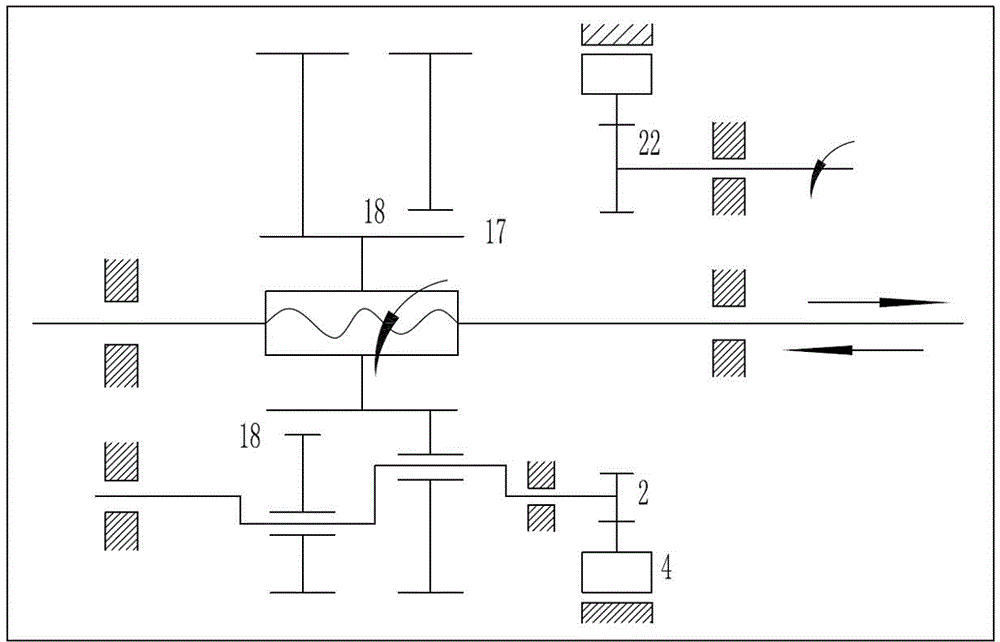

[0020] The present invention relates to a deceleration device for combined transmission of involute gear and cycloid gear, which is provided with a two-stage deceleration mechanism for combined transmission of planetary involute gear and cycloid gear in a closed cavity; the planetary The involute gear transmission reduction mechanism is formed by driving the sun gear 22 to rotate by the rotation of the motor 24, and then driving the inner ring gear 4 and the planetary gear 2 to rotate; the cycloid transmission reduction mechanism is composed of an eccentric shaft 9, a cycloid tooth Circle 18 and cycloidal wheel 17 constitute, and cycloidal ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com